Heated aboveground biogas digester

A biogas digester and heating technology, applied in the field of biogas digesters, can solve problems such as unfavorable promotion of clean energy, low fermentation degree of biogas digesters, and influence on normal use of biogas, and achieve the effects of simple structural improvement, guaranteed supply, and strong practicability

Inactive Publication Date: 2014-06-18

德阳嘉龙机械制造有限公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the low temperature of the traditional above-ground biogas digesters in winter, the fermentation degree of the biogas digesters is low and the gas production is low, which affects the normal use of biogas and is not conducive to the promotion of clean energy.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0013] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

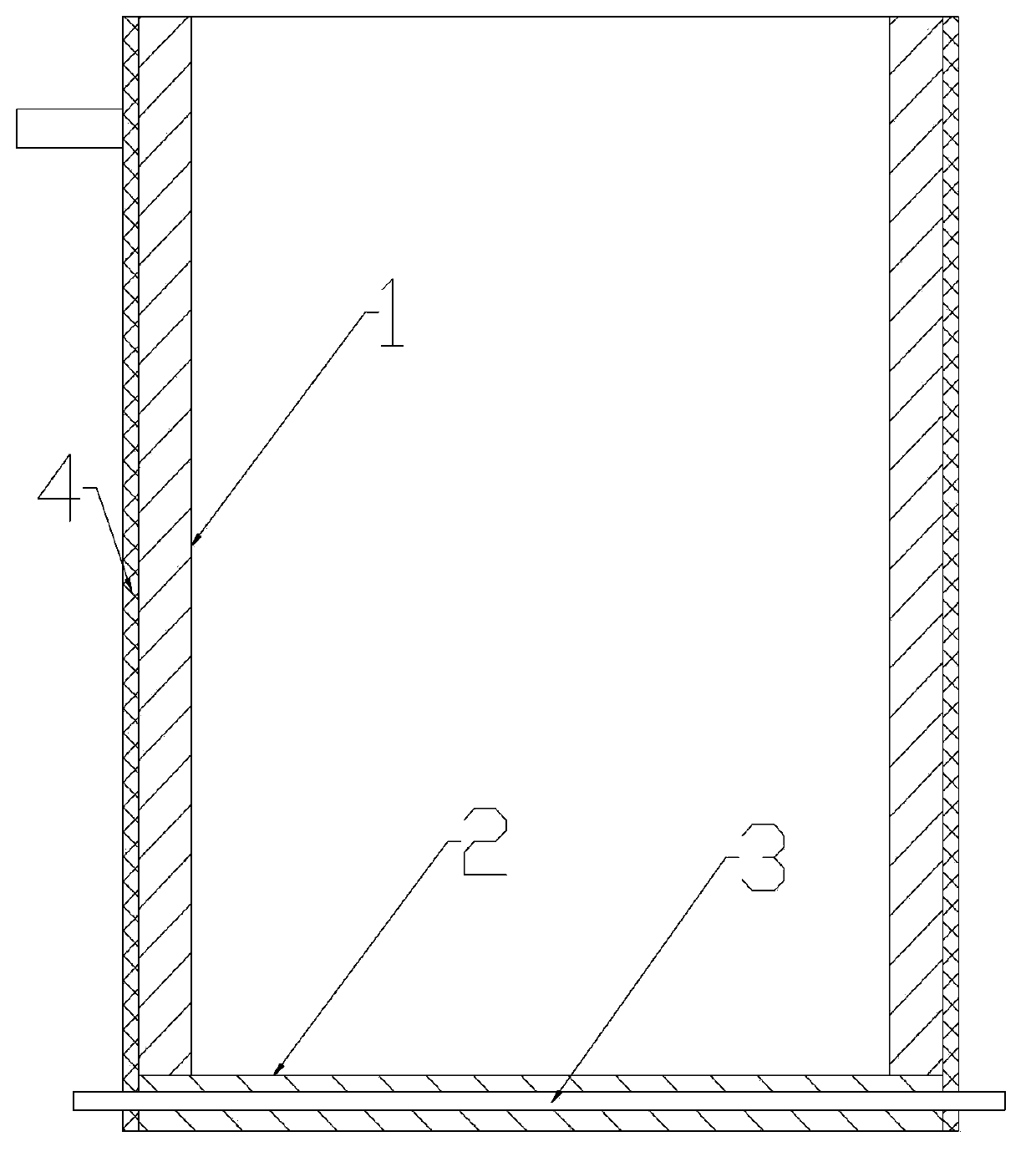

The invention discloses a heated aboveground biogas digester. The heated aboveground biogas digester comprises a cylindrical fermentation tank, a plurality of heating tubes are arranged in the pedestal of the fermentation tank, and both ends of the heating tubes are connected with a power supply. The heating tubes are arranged in the pedestal of the fermentation tank of the heated aboveground biogas digester, so an electric heating mode is adopted to improve the temperature in the fermentation tank in order to promote the biogas production and ensure the biogas supply, so it is in favor of using the biogas digester winter. The heated aboveground biogas digester has the advantages of improved simple structure, use and operation convenience, and strong practicality.

Description

technical field [0001] The invention relates to a biogas digester, in particular to an aboveground biogas digester. Background technique [0002] At present, above-ground biogas digesters have been widely used by people. Due to the low temperature in winter, the traditional above-ground biogas digesters have a low degree of fermentation and low gas production, which affects people's normal use of biogas and is not conducive to the promotion of clean energy. Contents of the invention [0003] The technical problem to be solved by the invention is to provide a heating type above-ground biogas digester that can increase the degree of fermentation and increase the gas production. [0004] In order to solve the problems of the technologies described above, the technical solution adopted in the present invention is: [0005] A heated above-ground biogas digester includes a cylindrical fermenter, a base of the fermenter is provided with a plurality of heating pipes, and both en...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C12M1/107C12M1/02

CPCC12M21/04C12M41/22Y02E50/30

Inventor 陈之平

Owner 德阳嘉龙机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com