Multi-layer moving combined house

A technology of combined houses and prefabricated houses, which is applied in the direction of construction and building construction, can solve the problems of difficulty in reaching 3 floors or higher, many installation procedures, and long installation period, so as to ensure stability and firmness , Convenient construction and operation, and short installation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

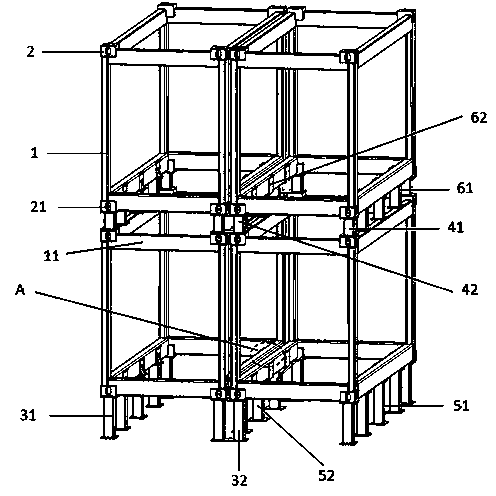

[0036] In this embodiment, a two-story composite house composed of four prefabricated house frames 1 is taken as an example:

[0037] 1. The first layer of installation:

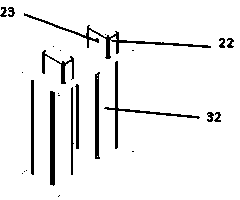

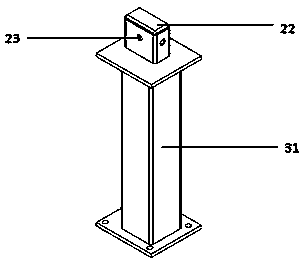

[0038] The ground is leveled, and the two prefab frames 1 are arranged side by side and fixed on the ground through two double-body load-bearing columns 32 and four single-body load-bearing columns 31. The specific implementation method is: the top of the double-body load-bearing columns 32 The heads 22 are respectively inserted into the fixing lassoes 2 on the two prefab frames 1, and fixed by screws to fix the two prefab frames 1 together. There are 2-4 double-body load-bearing columns 32 The double-body load-bearing frame 52, the bottom beams 11 of the two board room frames 1 are embedded in the mountain-shaped connecting piece 513 of the double-body load-bearing frame 52, and the bottom beam 11 and the double-body load-bearing frame 52 are fixed by screws, thereby further connecting the two The board ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com