Lithium Bromide Absorption Heat Exchange System with Supplementary Combustion for Simultaneous Heat Supply by Two Channels of Water

A lithium bromide absorption and heat exchange system technology, applied in the field of air-conditioning equipment, can solve problems such as waste of heating capacity of a heating pipe network, and achieve the effects of increasing the effective heat release temperature difference, increasing the amount of extraction and utilization, and improving the effective utilization of the temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

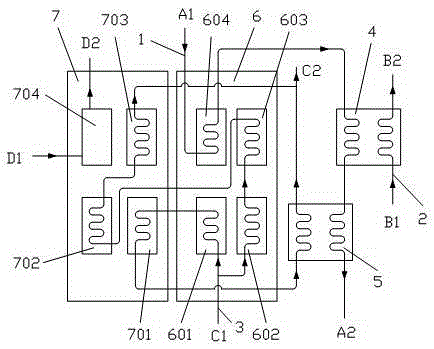

[0023] figure 2It is a diagram of an application example of the lithium bromide absorption heat exchange system with supplementary combustion of the two-way water supplying heat at the same time according to the present invention. The system consists of a primary network hot water pipeline system 1, a first secondary network hot water pipeline system 2, a second secondary network hot water pipeline system 3, a first heat exchanger 4, and a second heat exchanger 5. The hot water type lithium bromide absorption type unit 6 and the direct-fired lithium bromide absorption type unit 7 are constituted. The hot water type lithium bromide absorption unit 6 includes an evaporator 601 , an absorber 602 , a condenser 603 and a generator 604 . The direct-fired lithium bromide absorption unit 7 includes an evaporator 701 , an absorber 702 , a condenser 703 and a generator 704 . The primary network hot water from the primary network hot water pipeline system 1 first enters the generator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com