Omnibearing refrigeration refrigerator

An all-round, freezer technology, used in household refrigeration devices, coolers, lighting and heating equipment, etc., can solve the problems of increased power consumption, low refrigeration efficiency, increased compressor working time, etc., to reduce power consumption , the effect of improving the cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

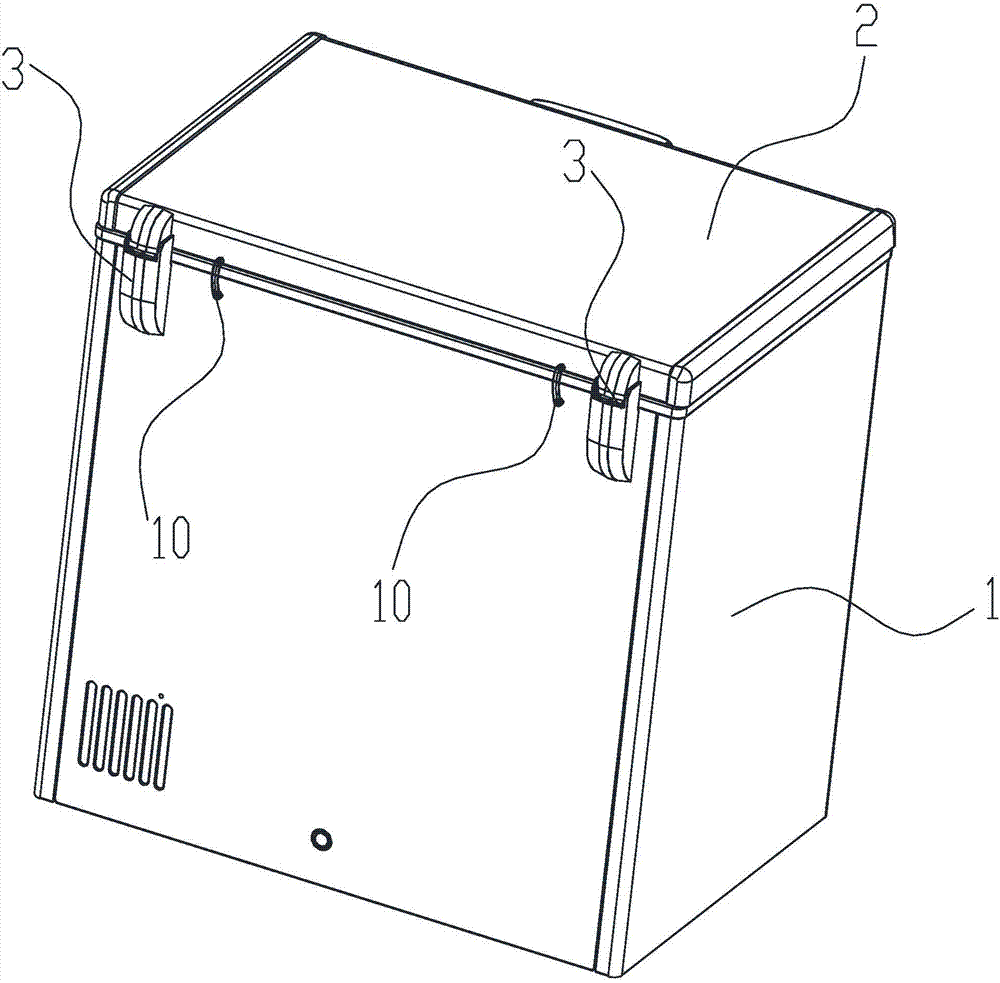

[0022] Such as figure 1 and figure 2 As shown, the freezer with all-round refrigeration includes a casing 1, a casing cover 2 and a refrigeration system.

[0023] A hinge 3 is provided on the connecting edge of the box body 1 and the box cover 2, one side of the hinge 3 is fixed on the outer wall of the box body 1, and the other side of the hinge is fixed on the outer wall of the box cover 2, thus through the hinge 3 The box body 1 and the box cover 2 are folded and connected to realize the movable opening and closing effect of the box cover 2 on the box body 1 .

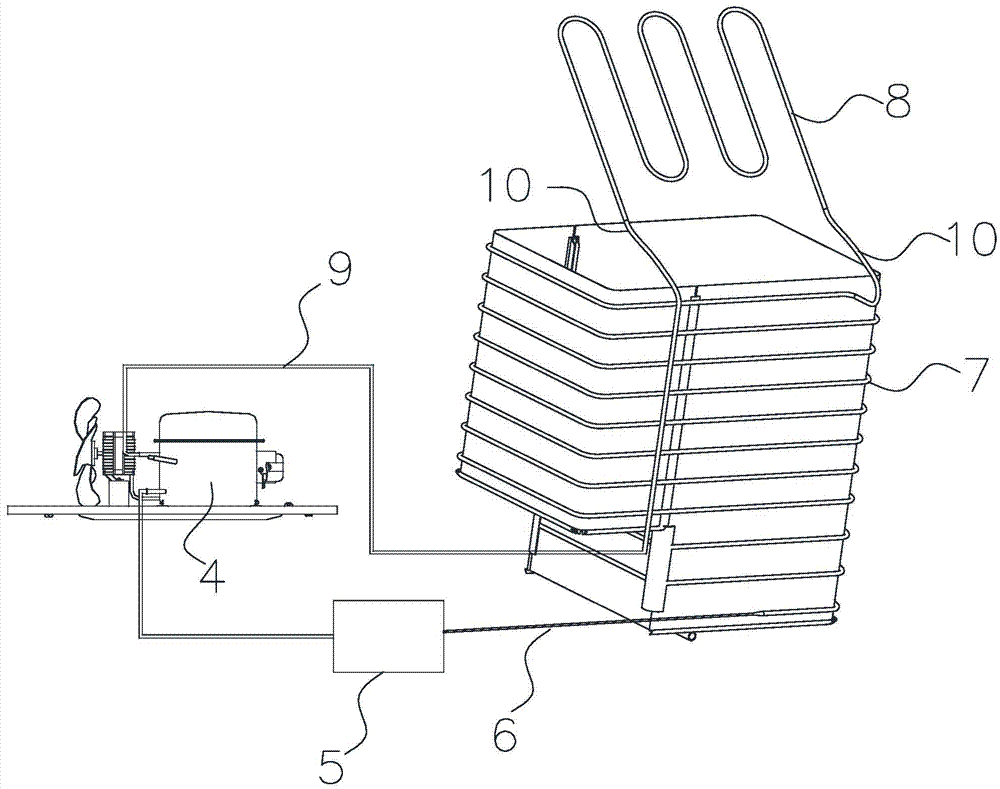

[0024] The refrigeration system includes a compressor 4, a condenser 5, a capillary tube 6, a box evaporator 7 and a cover evaporator 8, and the compressor 4, the condenser 5, the capillary tube 6, the box evaporator 7 and the cover evaporator 8 in sequence The second time is connected by pipeline to form a circulation loop. Wherein the box evaporator 7 is spirally arranged on the inner tank of the box 1 . The ...

Embodiment 2

[0030] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that:

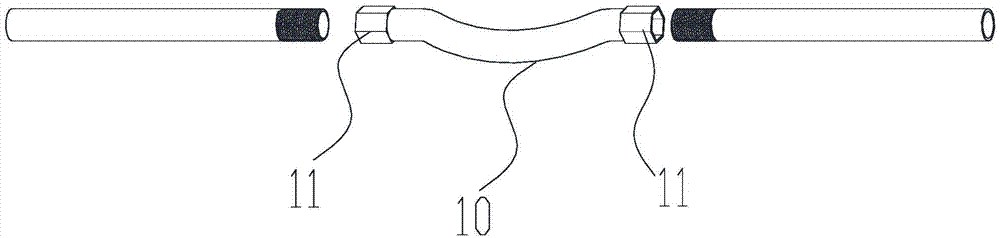

[0031] The joint includes a snap ring on the interface of the hose 10, a sealing ring is arranged on the inner periphery of the snap ring, and a snap groove is arranged on the outer periphery of the nozzle of the box evaporator 7 or the cover evaporator 8, and then the snap ring and the nozzle form a snap-fit assembly . The interfaces at both ends of the hose 10 are snap-connected with the nozzles of the box evaporator 7 or the cover evaporator 8 respectively, and the sealing ring is used to improve the sealing effect. The sealing clip is firm and reliable, which is convenient for disassembly, maintenance and replacement, and improves work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com