Modular generator

A generator and magnet technology, applied in the field of modular generators, can solve the problems of large generator loss, output power reduction, and difficult heat diffusion, etc., and achieve the effect of reduced volume, large output power, and favorable heat diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

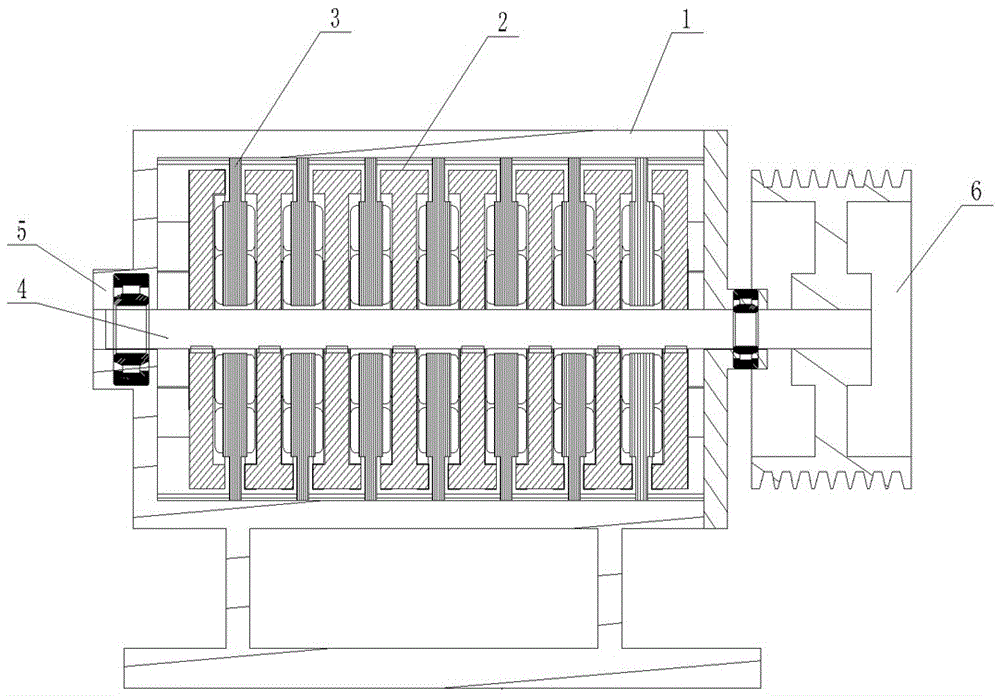

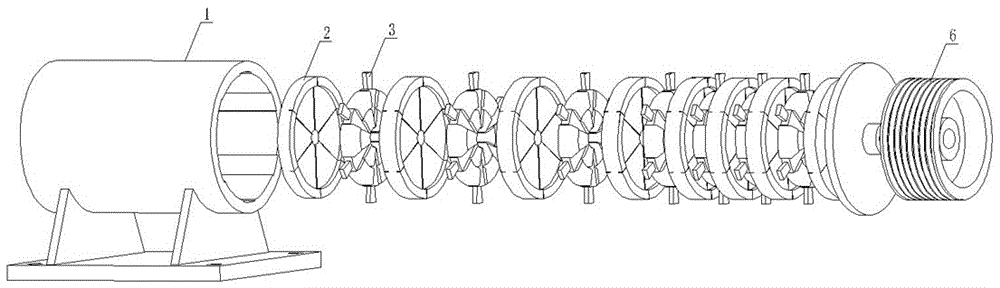

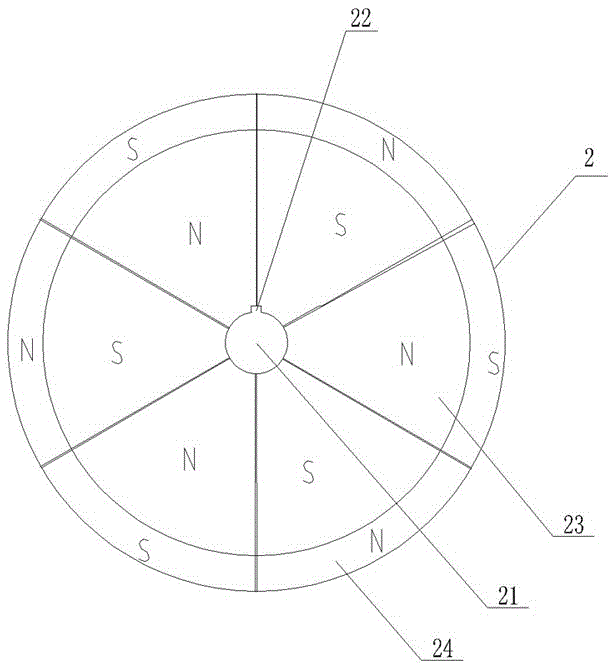

[0018] Refer to attached figure 1 And attached figure 2 , a modular generator, including a housing 1, at least two magnet rotors 2, at least one coil stator 3 and a drive shaft 4, the inside of the housing 1 is hollow and cylindrical, and the surface of the housing 1 is provided with vent holes, which help for the diffusion of heat. Both ends of the cylindrical housing 1 are respectively provided with shaft seats 5. In this embodiment, the magnet rotor 2 is provided with eight pieces, and the coil stator 3 is provided with seven pieces, that is, the two sides of the coil stator 3 are respectively provided with A magnet rotor 2, the combination of the magnet rotor 2 and the coil stator 3 is installed in the housing 1, the transmission shaft 4 runs through the housing 1, the combination of the magnet rotor 2 and the coil stator 3 and the pulley 6, and the transmission shaft 4 and the magnet rotor 2 are mutually Combined with the fixation, the belt pulley 6 drives the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com