Ultraviolet photochemical reactor device based on continuous flow technology

A photochemical reaction and reactor technology, applied in the field of optical reaction, can solve the problems of small heat release, strong monochromaticity of light, and high energy consumption of mercury lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

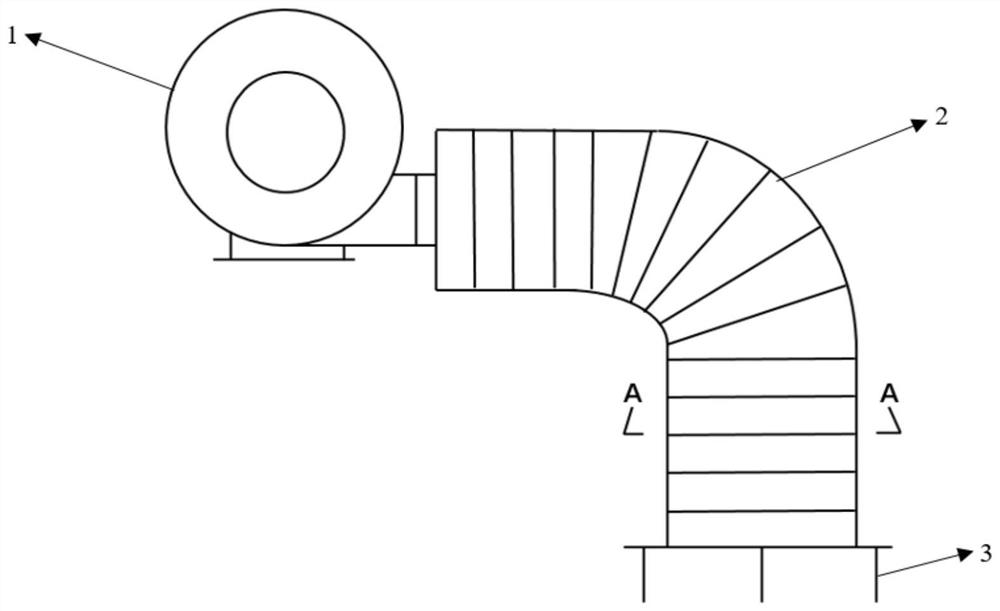

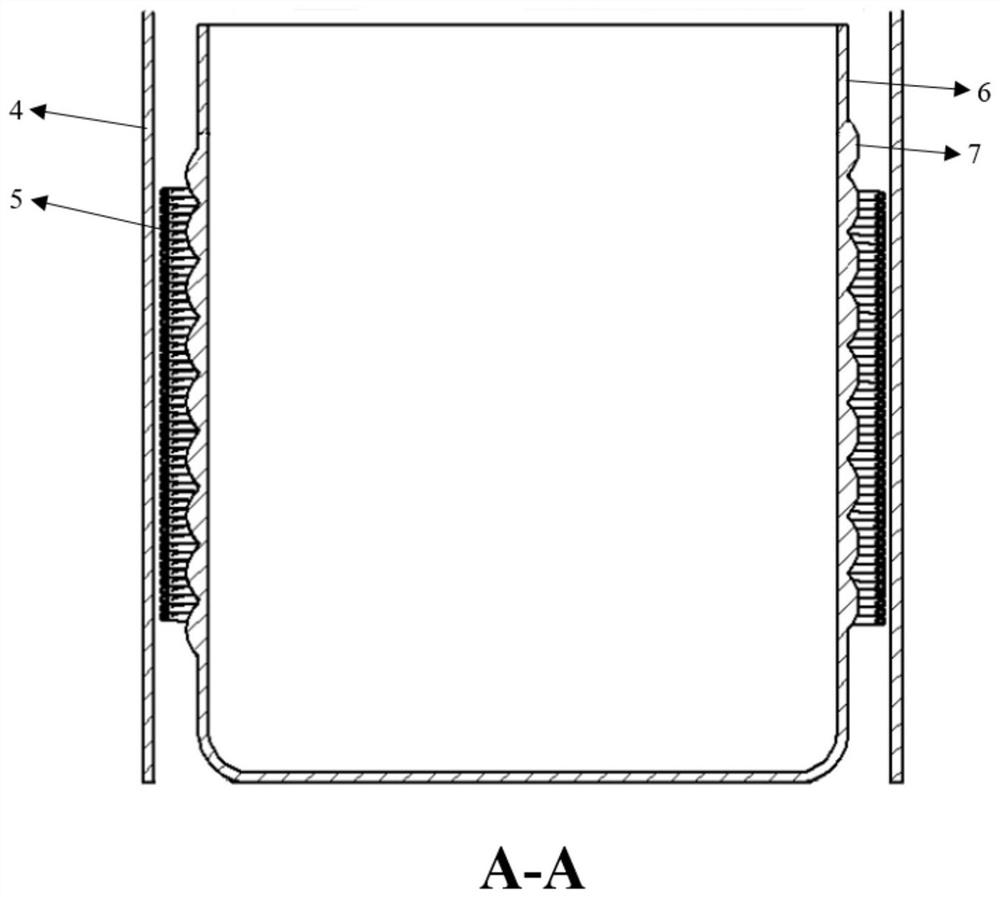

[0021] like figure 1 , figure 2 As shown, this embodiment includes: a blower 1 and a beaker 6 connected to it through an aluminum foil tube 2, wherein: the beaker 6 is provided with aluminum foil 4 outside, and the capillary reactor 5 and the ultraviolet LED lamp strip 7 are wound and arranged on the beaker 6 and between 4 sheets of aluminum foil.

[0022] The capillary reactor 5 is made of PFA, has an inner diameter of 1mm, a length of 12.5m, and a wall thickness of 0.3mm.

[0023] The blower 1 has an input power of 40W and an air volume of 1m 3 / min.

[0024] The aluminum foil tube 2 has an inner diameter of 120mm and a length of 1.5m, and can be stretched freely in the axial direction.

[0025] The material of the beaker 6 is silicate glass. Preferably, the inner diameter of the beaker is 80 mm, and the distance between the LED strip and the capillary is 5 mm.

[0026] The ultraviolet LED lamp strip 4 emits ultraviolet light with a characteristic wavelength of 365nm, ...

Embodiment 2

[0029] Compared with Example 1, the material of the capillary reactor 5 in this example is PFA, the inner diameter is 0.75mm, and the length is 8m.

[0030] The blower 1 has an input power of 60W and an air volume of 1.5m 3 / min

[0031] The inner diameter of the aluminum foil tube 2 is 120mm, and the length is 2m.

[0032] In this embodiment, the above system is used to carry out photosensitized cycloaddition reaction of norbornadiene. Preferably, the concentration of norbornadiene is 0.06mol / L, the photosensitizer used is tetraethyl Michler's ketone, and the solvent used is Acetone, the reaction residence time was 2 hours, and the product tetracycloheptane collected had a yield of 90%. Compared with the prior art where a single mercury lamp is used to irradiate the tank reactor, the reaction yield per hour is less than 20%.

Embodiment 3

[0034] Compared with Example 1, in this example, three groups of flexible light sources and capillary continuous flow reactors are set in parallel to increase the reaction flux per hour to 60mL / h.

[0035] In this embodiment, the above-mentioned system is used to carry out photosensitized cycloaddition reaction of norbornadiene. Preferably, the concentration of norbornadiene is 0.30mol / L, the photosensitizer used is tetraethyl Michler's ketone, and the solvent used is Acetone, the reaction residence time was 0.5 hour, and the product tetracycloheptane collected had a yield of 75%. Compared with the prior art where a single mercury lamp is used to irradiate the tank reactor, the space-time yield of the reaction is less than one-tenth of that of the continuous flow reactor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

| Optical power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com