Convection type heat dissipation power cabinet

A power cabinet and cabinet technology, applied in the field of convection cooling power cabinets, can solve the problems of unfavorable power cabinet high-power operation, slow heat dissipation, and large heat generation of power cabinets, and achieve excellent heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

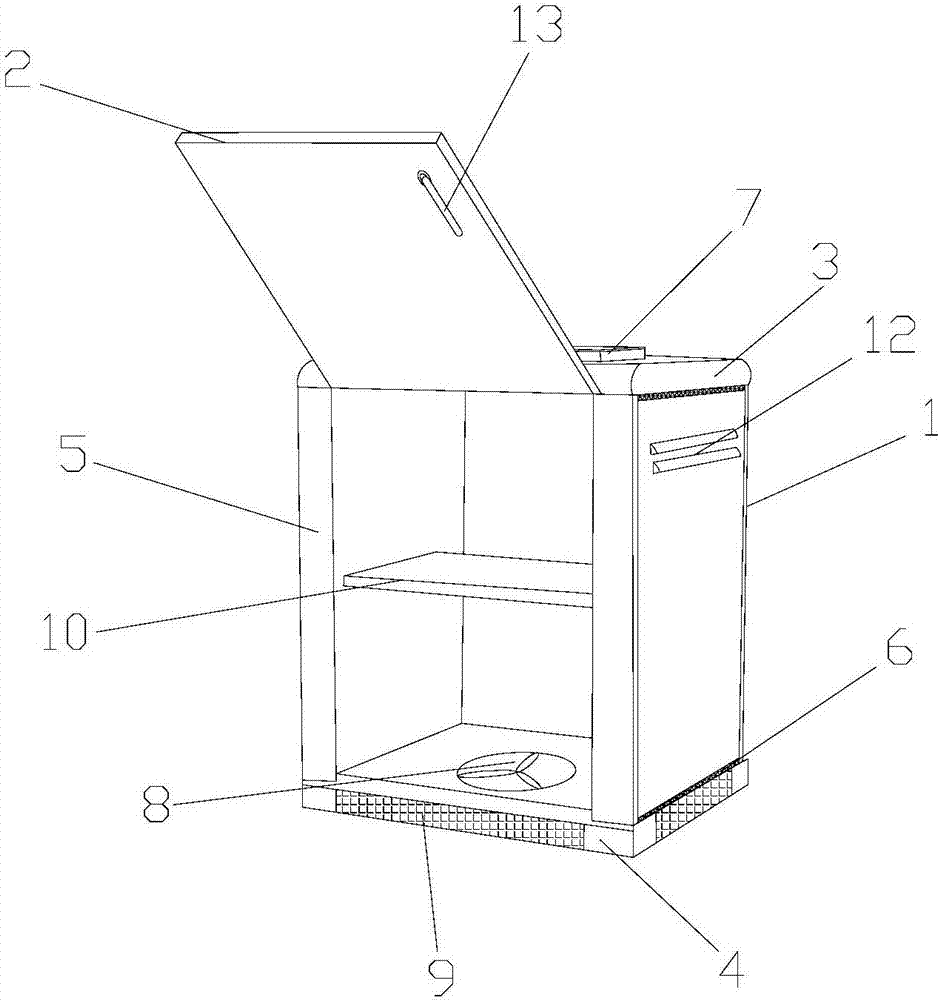

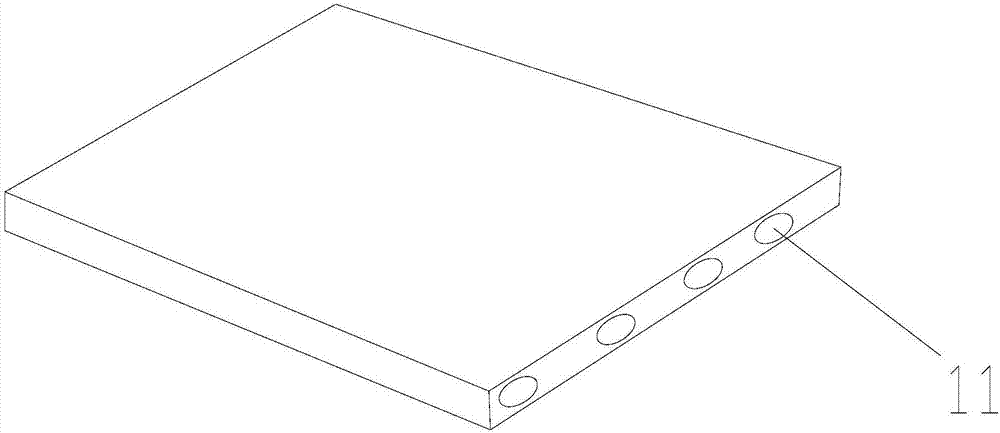

[0025] Such as Figure 1-2 As shown, a convection heat dissipation power cabinet includes a cabinet body 1 and a cabinet door 2, and the cabinet body 1 includes an upper cover 3, a lower cover 4 and side panels 5, and the upper cover 3 and the lower cover 4 are both Self-tapping screws (not shown) are installed, and the self-tapping screws are threadedly connected with the side plate 5, and the self-tapping screws are all embedded in the upper cover 3 and the lower cover 4, and the upper cover 3 and the lower cover 4 are connected with the lower cover 4. Conductive cloth pads 6 are arranged between the side plates, the upper cover 3 is provided with a blower 7, the lower cover 4 is hollow, the lower cover 4 is equipped with an exhaust fan 8, and the exhaust fan 8 To be embedded in the lower cover 4, the lower cover 4 is provided with an air vent 9, the side plate 5 is provided with an aluminum veneer 10, and the aluminum veneer 10 is provided with a vent (not shown) , a magne...

Embodiment 2

[0040] Such as Figure 1-2 As shown, a convection heat dissipation power cabinet includes a cabinet body 1 and a cabinet door 2, and the cabinet body 1 includes an upper cover 3, a lower cover 4 and side panels 5, and the upper cover 3 and the lower cover 4 are both Self-tapping screws (not shown) are installed, and the self-tapping screws are threadedly connected with the side plate 5, and the self-tapping screws are embedded in the upper cover 3 and the lower cover 4, and the upper cover 3 and the lower cover 4 are connected with the lower cover 4. Conductive cloth pads 6 are arranged between the side plates, the upper cover 3 is provided with a blower 7, the lower cover 4 is hollow, the lower cover 4 is equipped with an exhaust fan 8, and the exhaust fan 8 To be embedded in the lower cover 4, the lower cover 4 is provided with an air vent 9, the side plate 5 is provided with an aluminum veneer 10, and the aluminum veneer 10 is provided with a vent (not shown) , a magnet 11...

Embodiment 3

[0055] Such as Figure 1-2 As shown, a convection heat dissipation power cabinet includes a cabinet body 1 and a cabinet door 2, and the cabinet body 1 includes an upper cover 3, a lower cover 4 and side panels 5, and the upper cover 3 and the lower cover 4 are both Self-tapping screws (not shown) are installed, and the self-tapping screws are threadedly connected with the side plate 5, and the self-tapping screws are all embedded in the upper cover 3 and the lower cover 4, and the upper cover 3 and the lower cover 4 are connected with the lower cover 4. Conductive cloth pads 6 are arranged between the side plates, the upper cover 3 is provided with a blower 7, the lower cover 4 is hollow, the lower cover 4 is equipped with an exhaust fan 8, and the exhaust fan 8 To be embedded in the lower cover 4, the lower cover 4 is provided with an air vent 9, the side plate 5 is provided with an aluminum veneer 10, and the aluminum veneer 10 is provided with a vent (not shown) , a magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com