Automatic maintenance equipment of probe card and method thereof

A technology for repairing equipment and probe cards, which is applied to measuring devices, instruments, measuring electrical variables, etc., can solve the problems of inability to guarantee the consistency of maintenance accuracy, affecting work efficiency, and easy loss of talents, so as to solve the problem of manual fatigue operation, Speed up maintenance efficiency and avoid the effect of human maintenance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with various embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

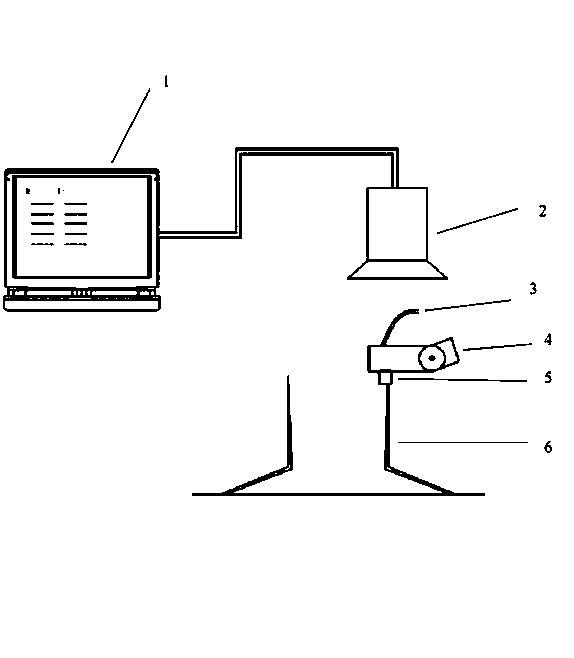

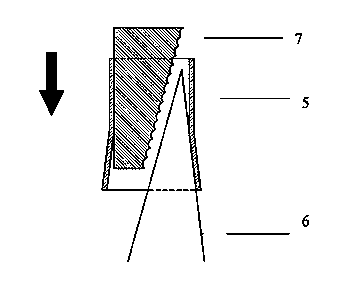

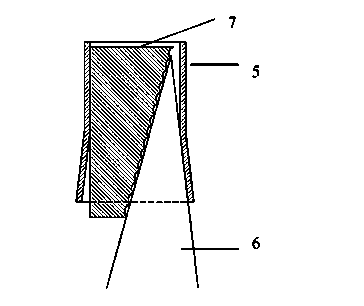

[0036] ginseng Figure 1 to Figure 3 As shown, an embodiment of the probe card automatic maintenance equipment provided by the present invention includes a microcomputer 1, a microscope 2, a vacuum suction pipe 3, a mechanical arm 4, and a vacuum suction nozzle 5. The microcomputer 1 and the microscope 2 connected, and the microcomputer 1 is the micro control unit in this embodiment, wherein the original factory coordinate value of the probe card is preset, and the actual coordinate value of the probe card is detected by the microscope 2, when the actual coordinate value and the original coordinate valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com