Charging roller and preparation method thereof

A technology of charging rollers and fillers, applied in circuits, electrical components, corona discharge devices, etc., can solve environmental and human hazards, and achieve the effects of avoiding pollution, simplifying procedures, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

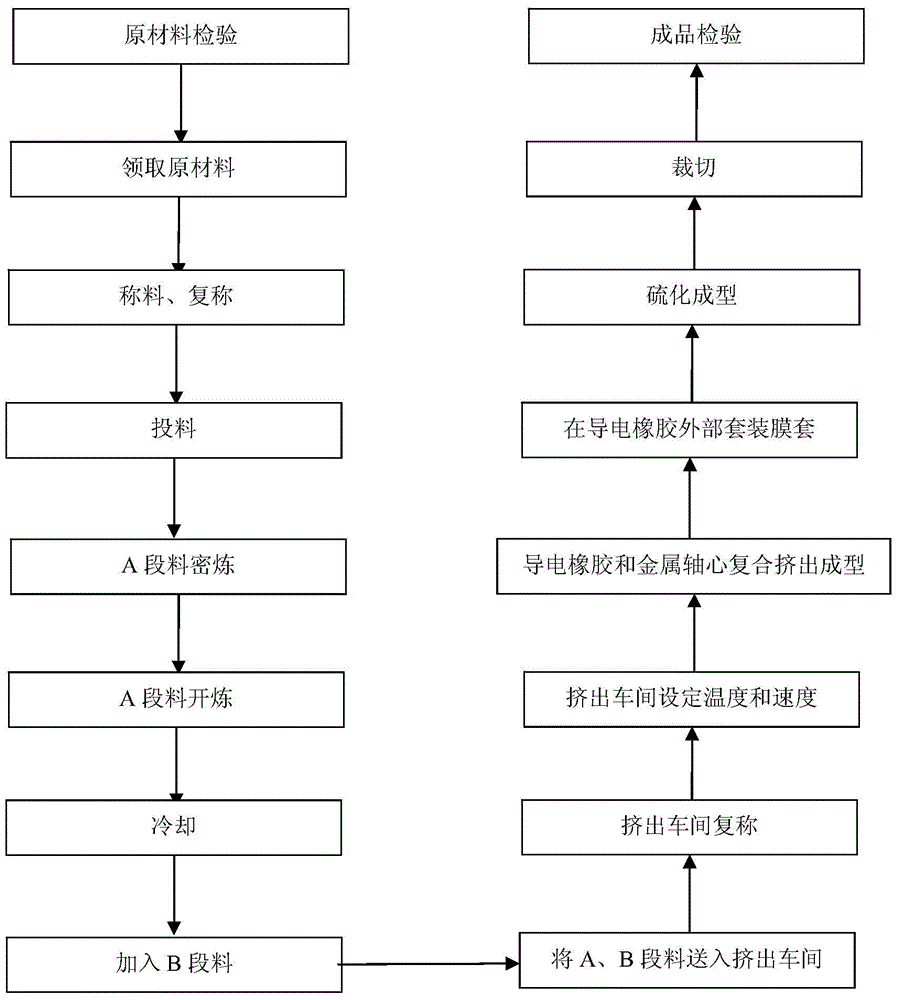

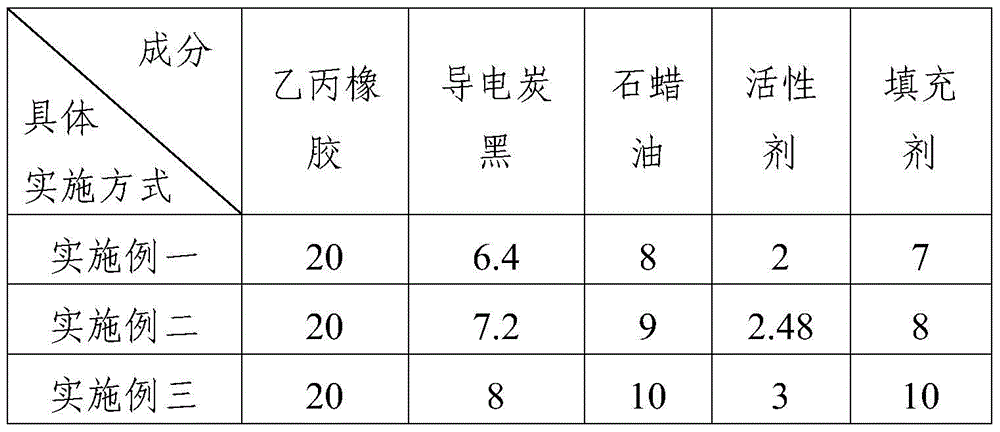

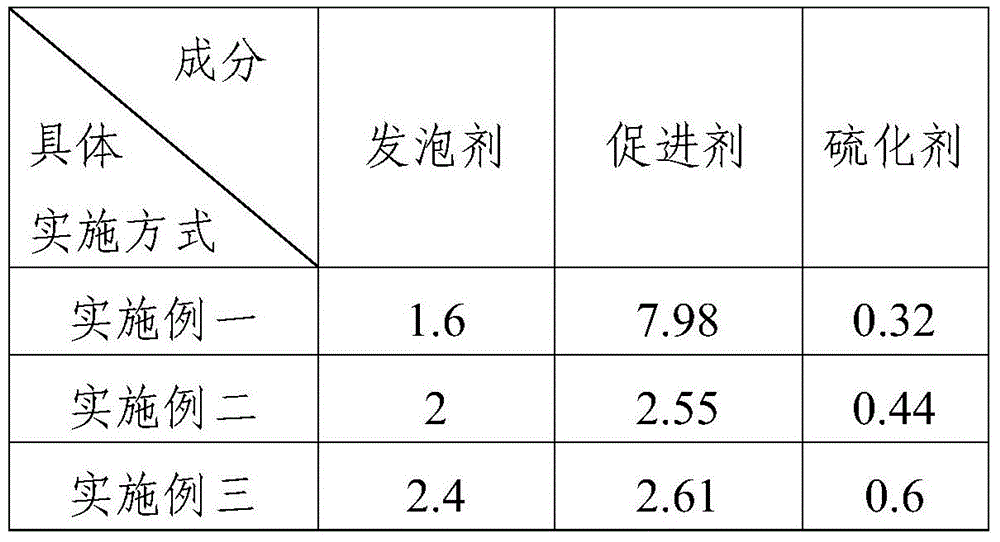

[0042] A charging roller of the present invention, which includes a metal shaft and conductive rubber sleeved on the outside of the metal shaft, a film cover is provided on the outside of the conductive rubber, and the film cover and the conductive rubber are integrally formed, and the conductive rubber is made of A section material and B section material, the weight percentage of A section material and B section material is: 100:9~11, the weight percentage of the A section material and B section material is preferably: 100:10; A section material is mixed Ethylene-propylene rubber with conductive carbon black, the percentage by weight of conductive carbon black and ethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com