Failure analysis method for numerically-controlled machine tool

A fault analysis method and technology of CNC machine tools, which are applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., and can solve problems such as failure to consider failure correlation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

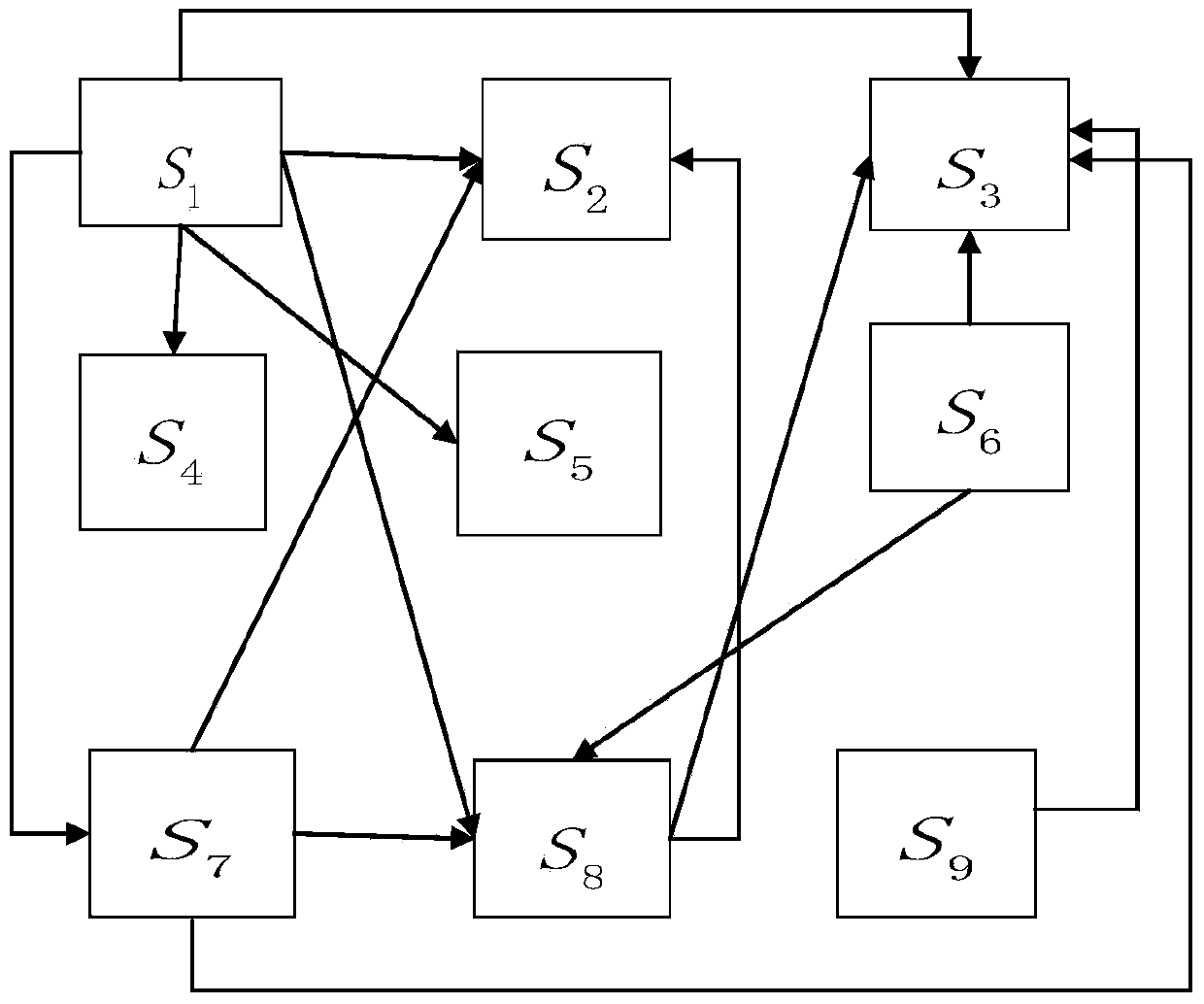

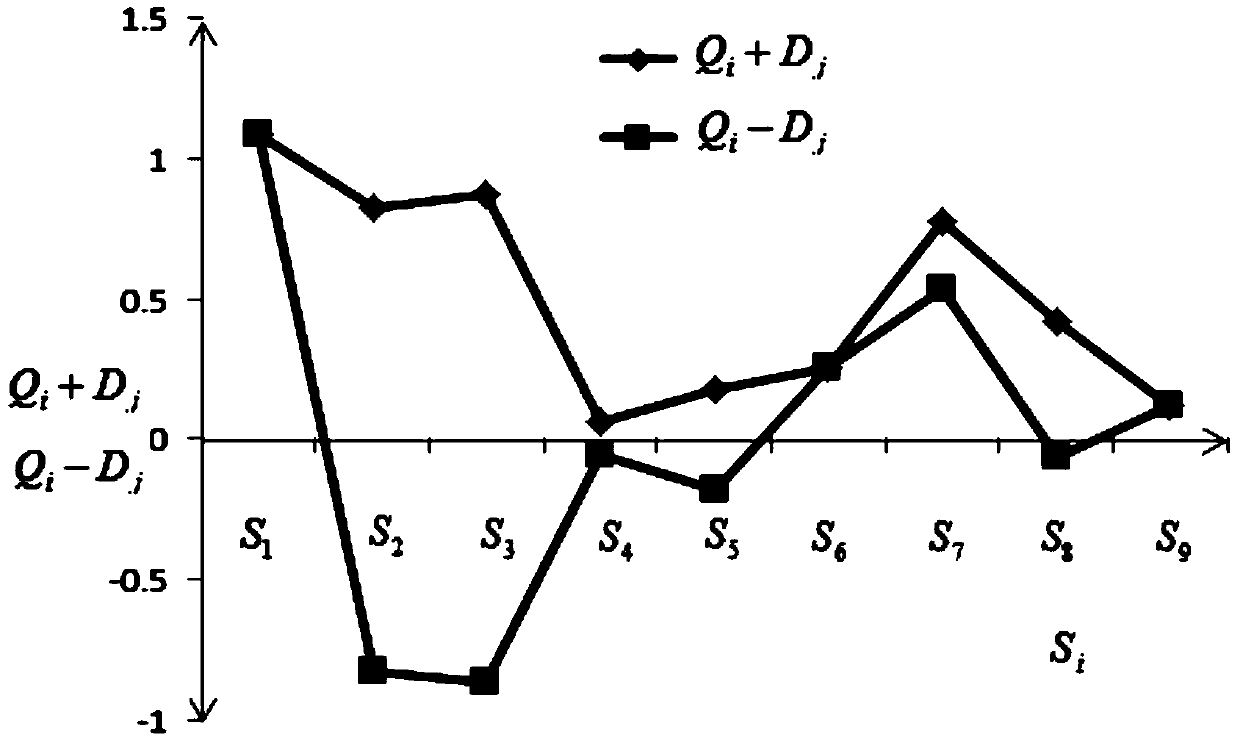

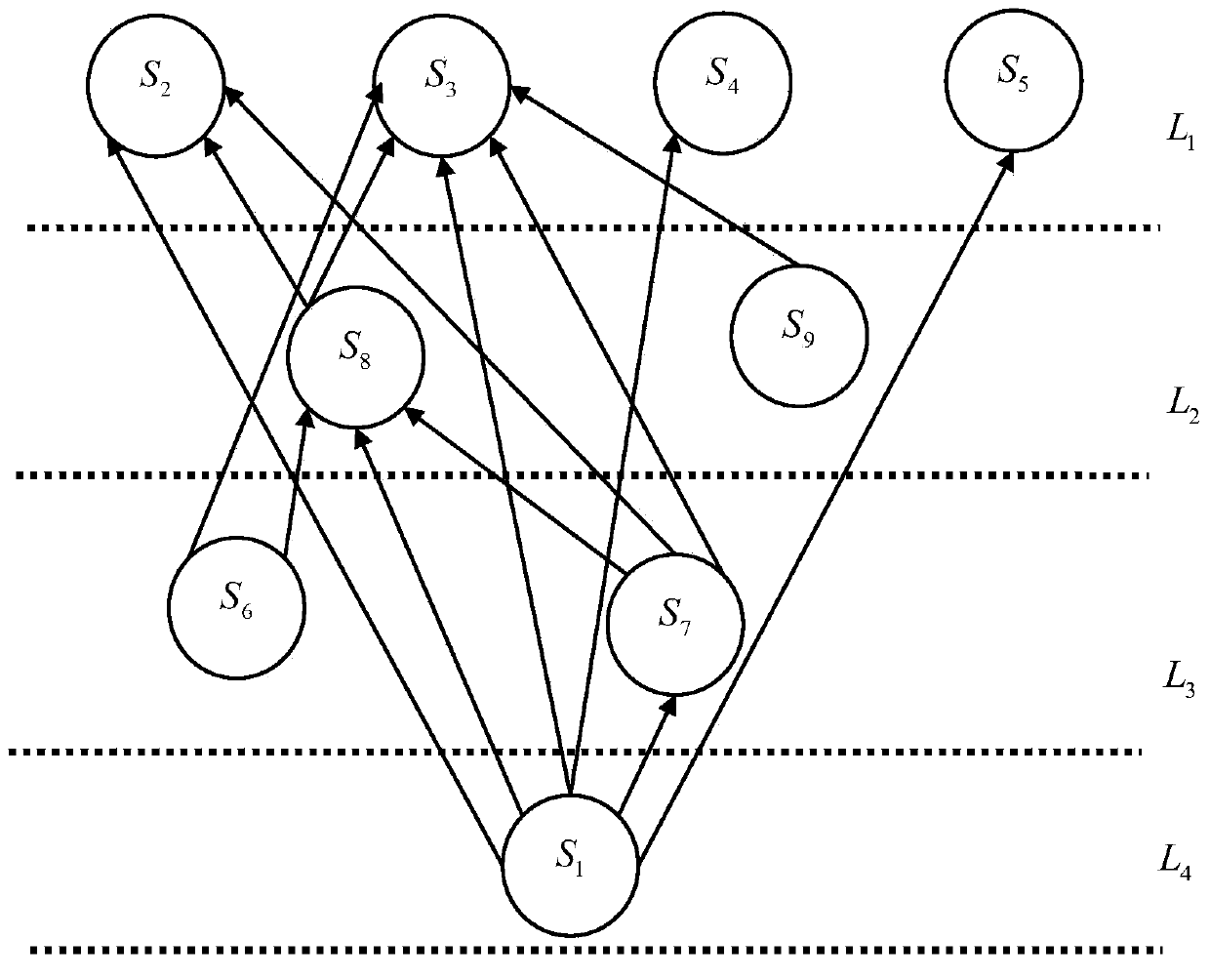

[0129] The present invention takes a certain series of numerically controlled machine tools as an example, combines fault statistical related data, considers fault subsystem correlation, adopts DEMATEL method, applies directed graph and matrix operation to obtain fault subsystem comprehensive impact matrix and correlation degree; and integrates ISM method, The logical relationship of many factors interacting with each other is visually represented by a multi-level hierarchical structure model, and the key subsystem is obtained by integrating the correlation degree and the multi-level hierarchical structure model. In order to further determine the key failure modes of key subsystems, FMECA technology is used to conduct hazard analysis on key subsystems, so as to find out key failure modes and clarify the focus of reliability improvement. The systematic application of this method is of great significance to reliability research such as fault diagnosis and location, and system rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com