Fuel suspended substance sedimentation detecting system

A detection system and suspended solids technology, applied in the direction of measuring devices, material inspection products, and material analysis through optical means, can solve the problems of large errors, influence of detection results, difficult storage and analysis of recorded data, etc., to improve automation degree, the effect of enriching research tools and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further illustrate the present invention, below in conjunction with embodiment is described in more detail.

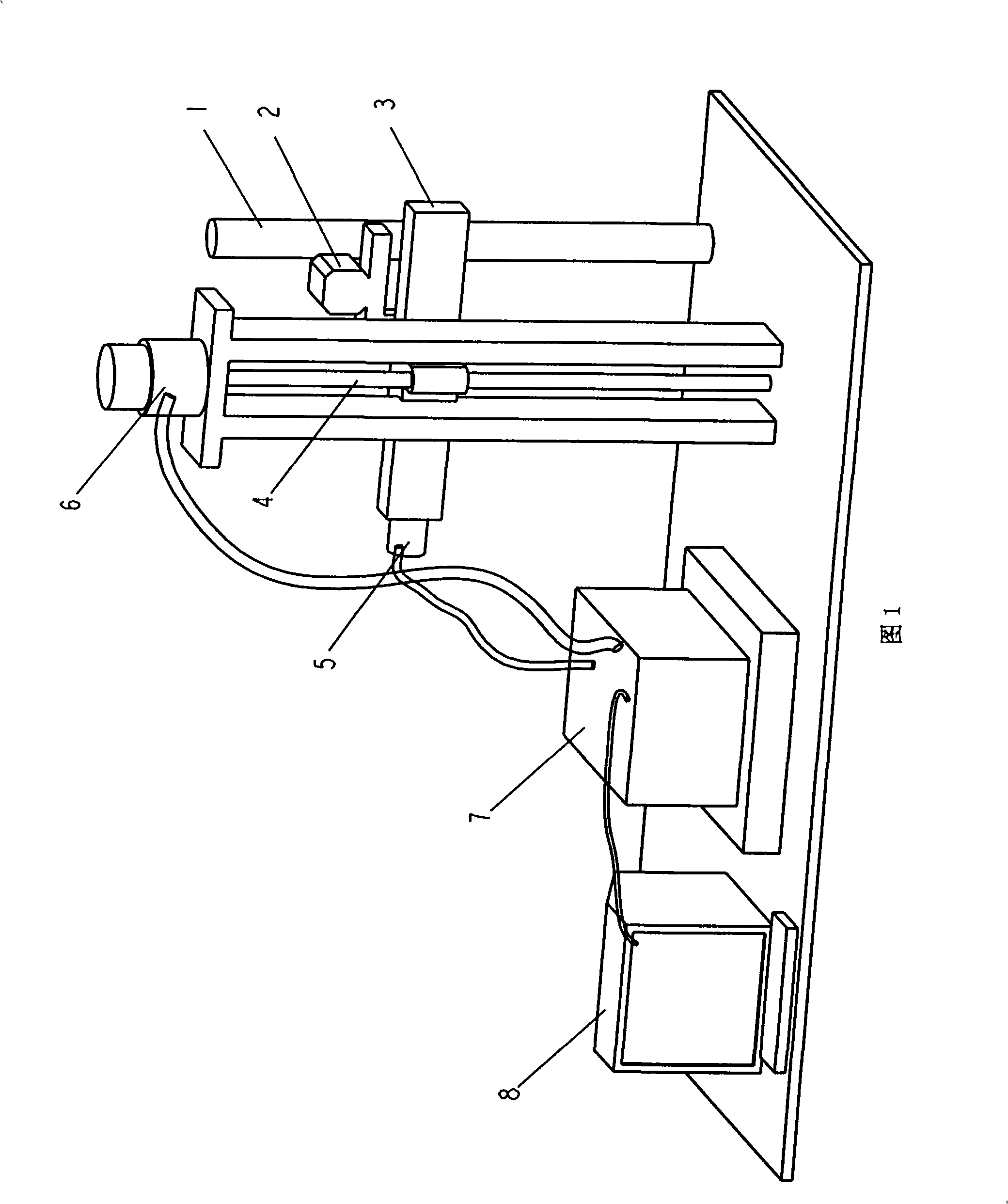

[0040] Fig. 1 is a structural schematic diagram of the fuel oil suspended solids settlement detection system of the present invention. The system is composed of five parts: a computer 8, a system controller 7, a high-precision numerical control coordinate frame composed of a cross arm 3 and a longitudinal arm 4, a camera 2 and a settlement column 1. The camera 2 is installed on the movable plate on the cross arm 3, and can move horizontally on the cross arm 3; the cross arm 3 is placed on the movable plate of the longitudinal arm 4, and can move vertically; in this way, the camera 2 can be in a plane Move arbitrarily; set a settling column 1 in front of the camera 2, the settling column 1 is made of hard glass, requires good transparency, can be taken off on the detection platform, and can be fixed upright in front of the camera 2 again.

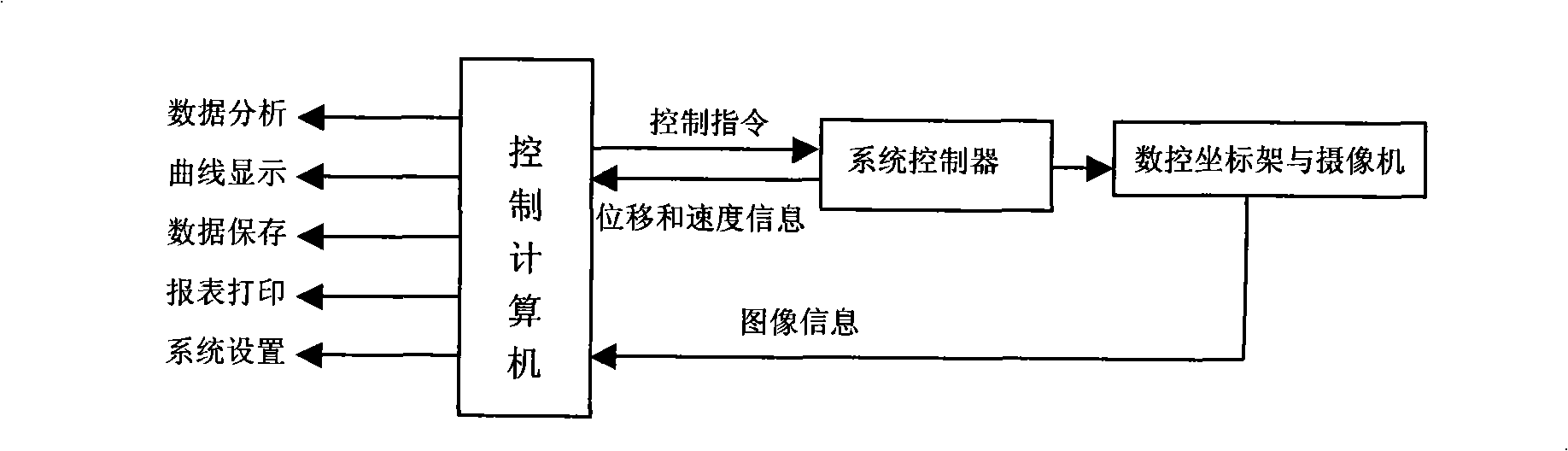

[0041] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com