A ceramic heater

A technology of ceramic heating sheets and ceramic sheets, which is applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., and can solve the problems of large number of leads, uneven heating, and small heating area of heating sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

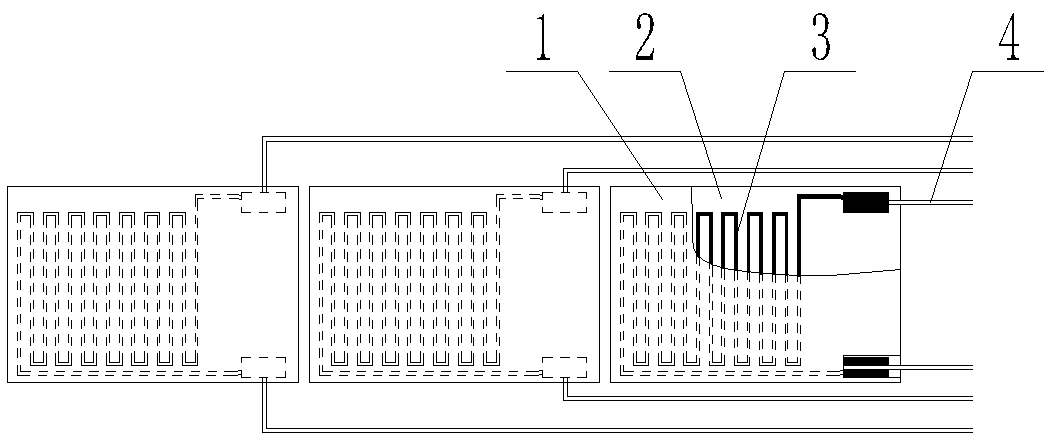

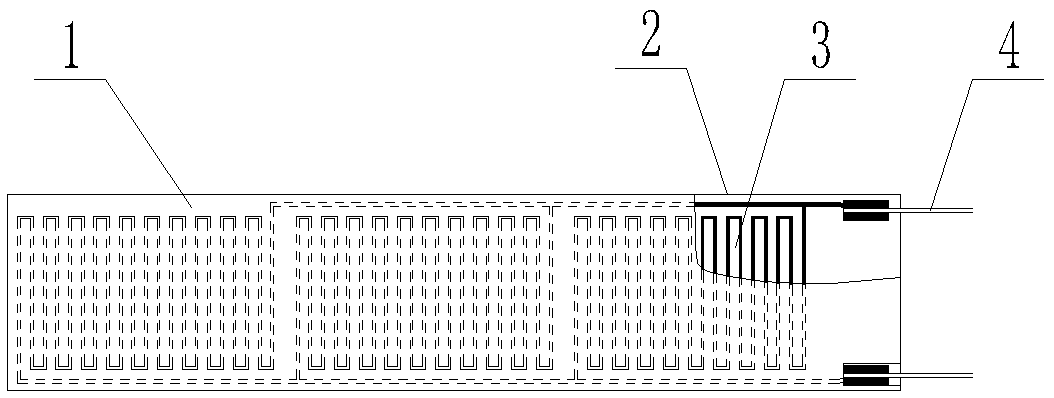

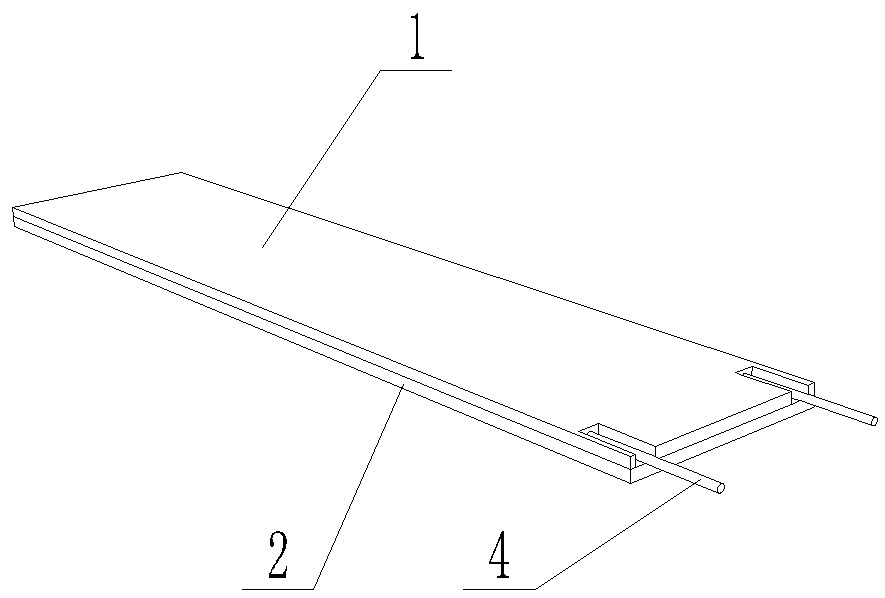

[0013] figure 1 A schematic diagram of the combination of multiple ceramic heating chips in the background technology to achieve large-area heating is given. When the heating component requires a large heating area, a combination of multiple ceramic heating chips is required. figure 1 Shown is the combination of three ceramic heating sheets. Since the heating area of a single such ceramic heating sheet is small, a combination of three such ceramic heating sheets can achieve large-scale heating. Each such ceramic heating sheet is composed of an upper ceramic heating sheet. Sheet 1, lower ceramic sheet 2, heating resistor 3, and lead wire 4. There is a heating blind area between adjacent ceramic heating sheets, resulting in uneven heating, and each ceramic heating sheet requires a set of lead wires 4, and each group has two lead wires 4. The combination of three such ceramic heating chips requires three sets of six lead wires 4 in total, resulting in a large number of lead wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com