Heat dissipation device

A heat dissipation device and body technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of inability to have remote heat dissipation effect, poor heat dissipation speed, narrow heat dissipation range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

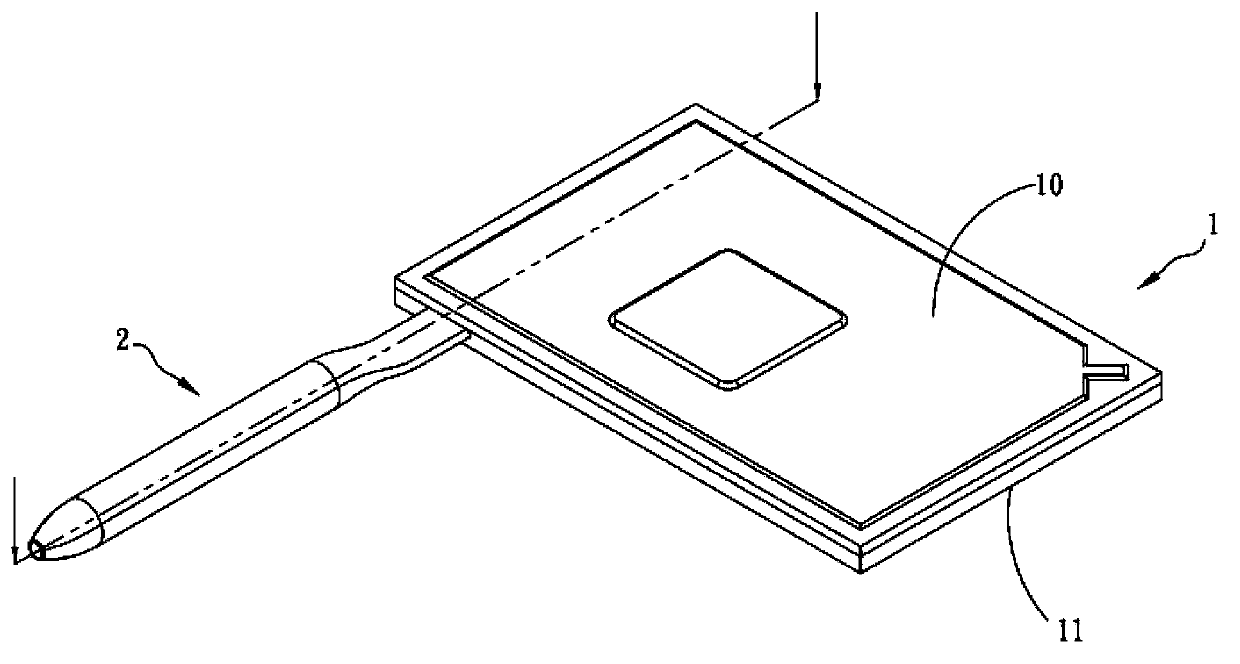

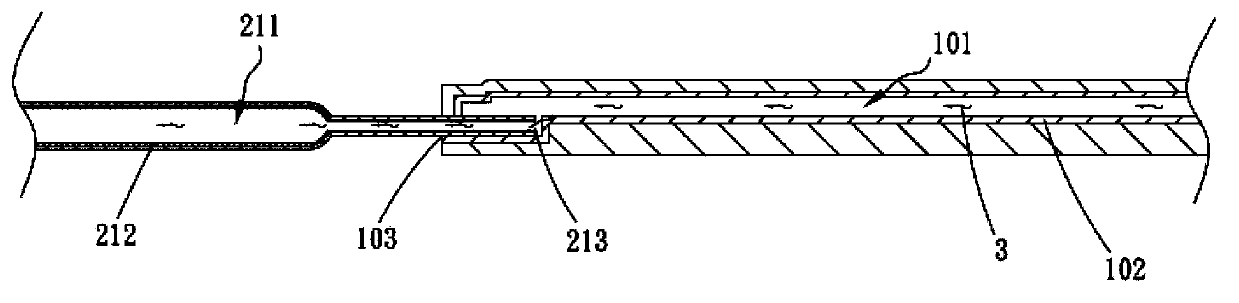

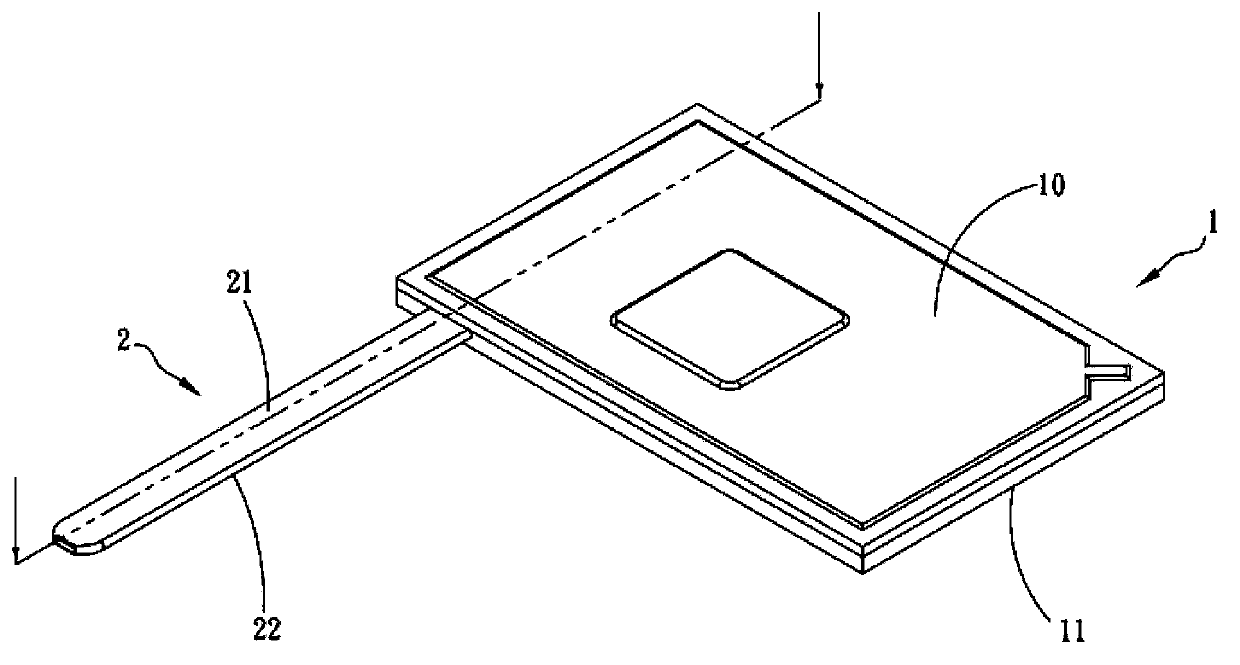

[0038] see Figure 1A , Figure 1B , is a three-dimensional combined view and a cross-sectional view of the first embodiment of the heat dissipation device of the present invention. A heat dissipation device includes a first body 1, a second body 2 and a working fluid 3. The first body 1 has a first Plate body 10 and a second plate body 11 relative to the first plate body 10, the first and second plate bodies 10, 11 correspond to the cover and jointly define a first chamber 101, the inner wall of the first chamber 101 is provided with There is a first capillary structure 102, the first capillary structure 102 can be any one of sintered powder body, grid body, fiber body, foam material and porous material, and the first body 1 also has an orifice 103;

[0039] The aforementioned s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com