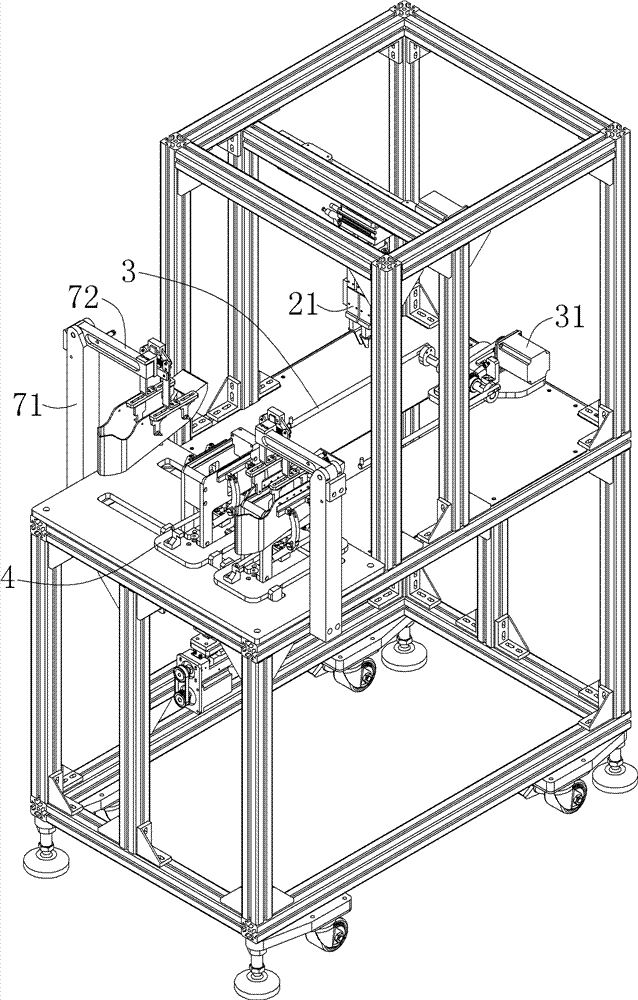

Upper transmission mechanism of automatic lacing machine

A transmission mechanism and automatic wearing technology, applied in footwear, shoe bindings, clothing, etc., can solve the problems of shoelace failure, high matching accuracy, and high cost of the driving mechanism, achieving accurate positioning, convenient feeding, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

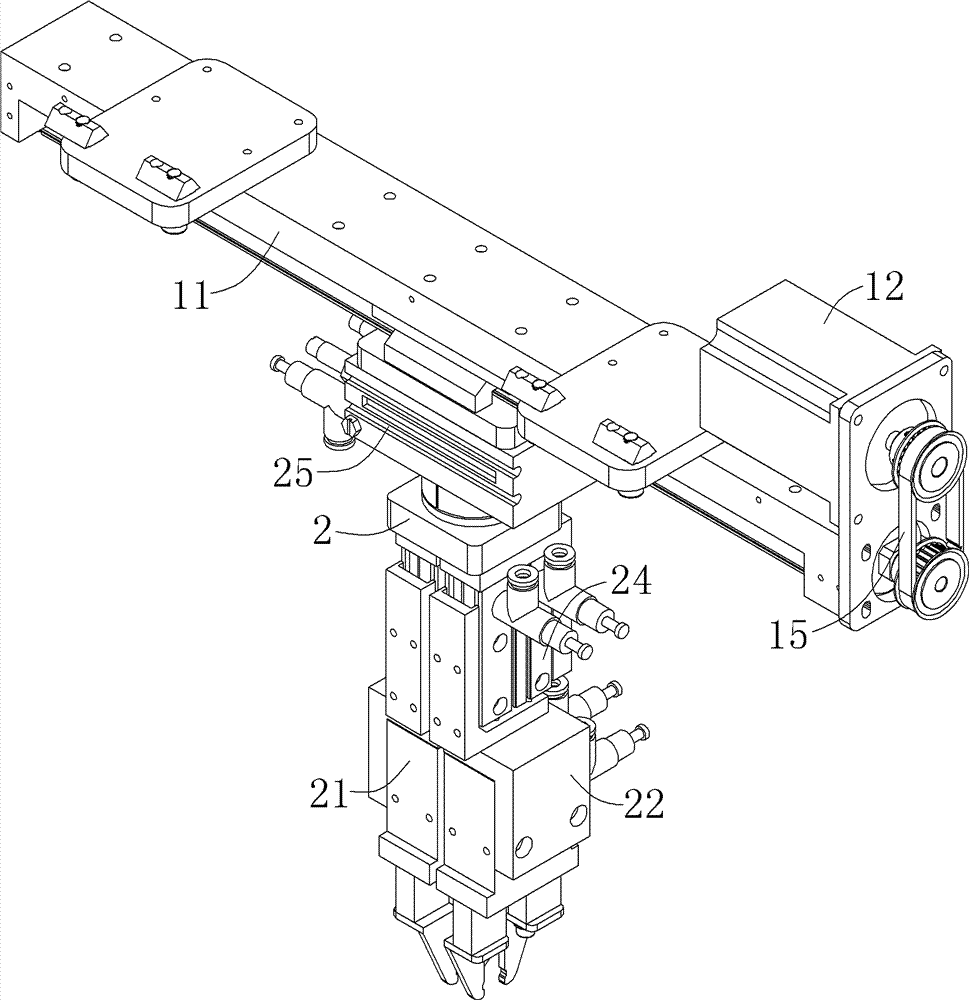

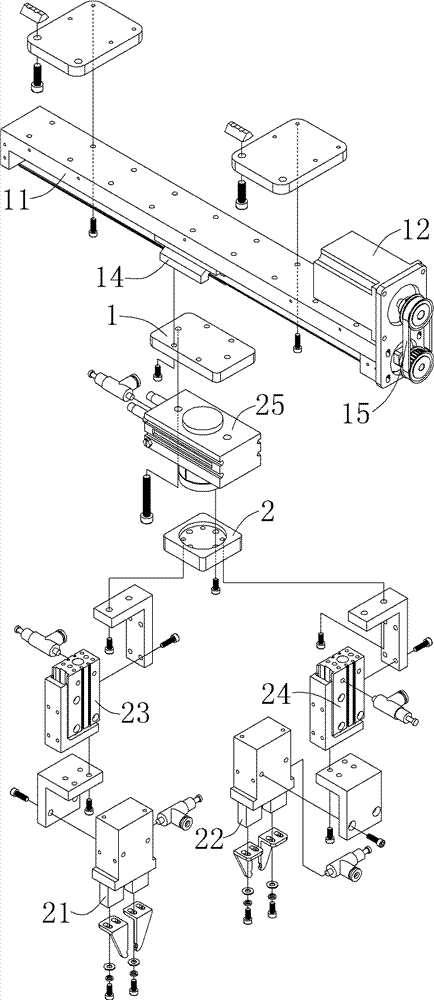

[0027] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] Figure 1 to Figure 9 Shown is the structural representation of the present invention.

[0029] The automatic shoelace machine includes a clamp mounting base 1 capable of linear motion in the X direction, a rotating seat 2 capable of rotating motion is provided on the clamp mounting base 1, and a first lifting cylinder 23 is arranged on the rotating base 2. The first clamp 21 and the second clamp 22 driven by the second lift cylinder 24 . The first clamp 21 and the second clamp 22 can clamp the shoelace ends, and under the drive of the clamp mounting base 1, alternately clamp the shoelace ends and pass the shoelace ends through the shoelace holes on the upper.

[0030] Such as Figure 1 to Figure 3 As shown, the clamp mounting base 1 is located on the upper part of the frame, and has an X-direction driving motor 12 that drives the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com