Rotating shaft geometric error identification method commonly used for five-axis numerical control machine tool

A technology of geometric error and CNC machine tools, which is applied to metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as not considering the influence of translational axis errors, and achieve good measurement integrity and high measurement accuracy , The effect of high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

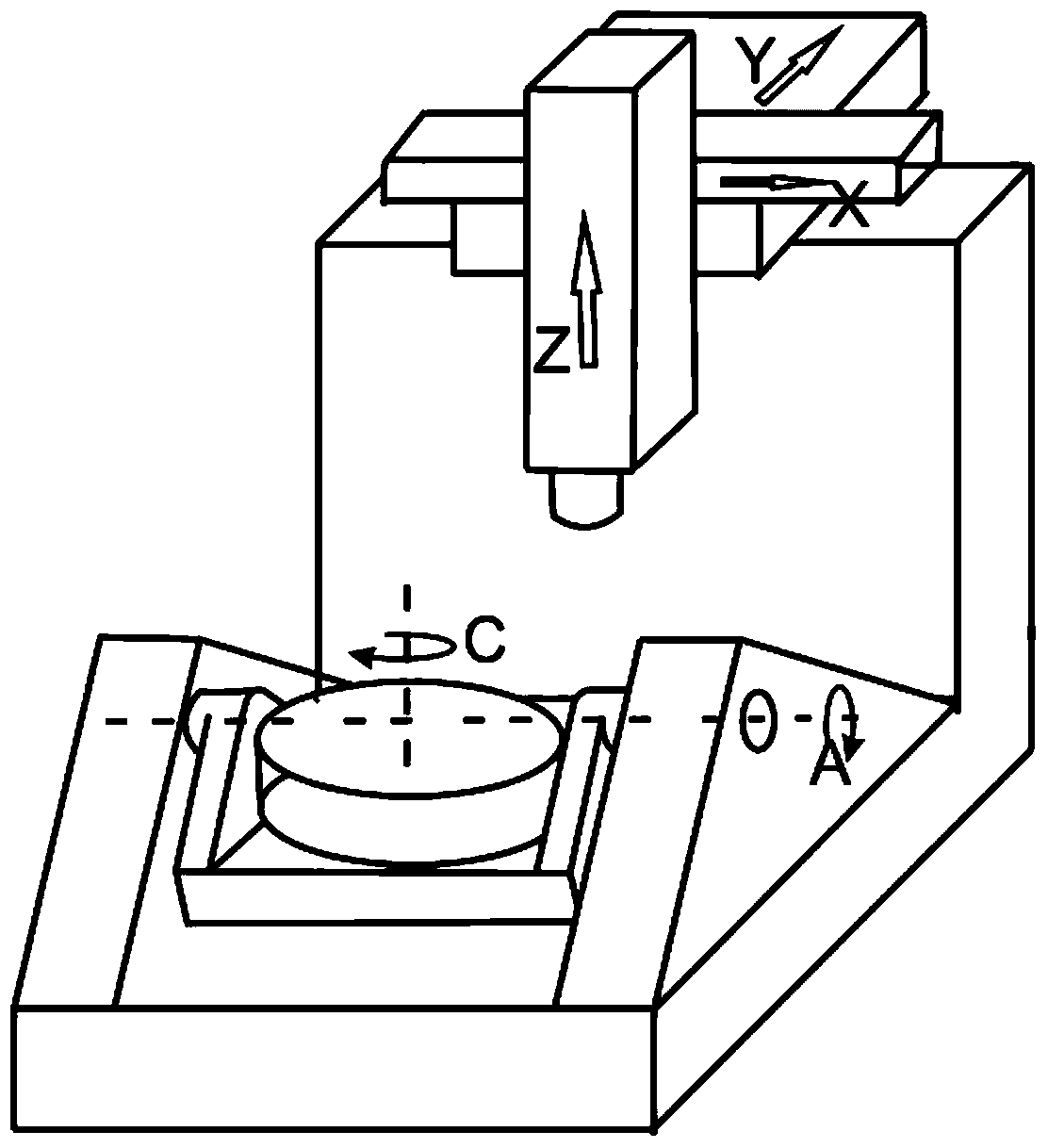

[0045] attached Figure 6 Shown is the flow chart of the method for identifying the geometric error of the universal rotary axis of the five-axis CNC machine tool of the present invention, with the attached figure 1 Shown is a schematic diagram of a CAFYXZ five-axis CNC machine tool, taking this machine tool as an example to illustrate the identification method of the rotary axis.

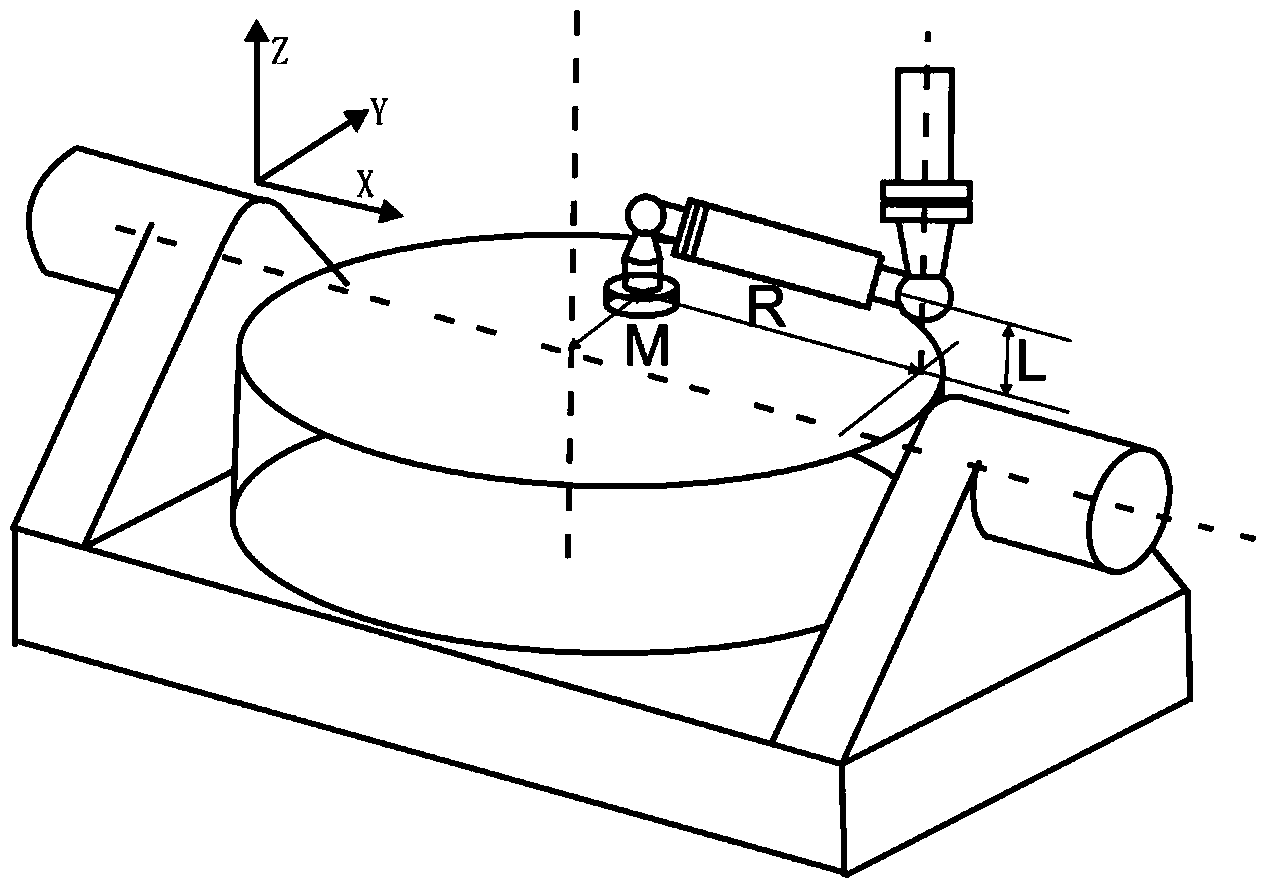

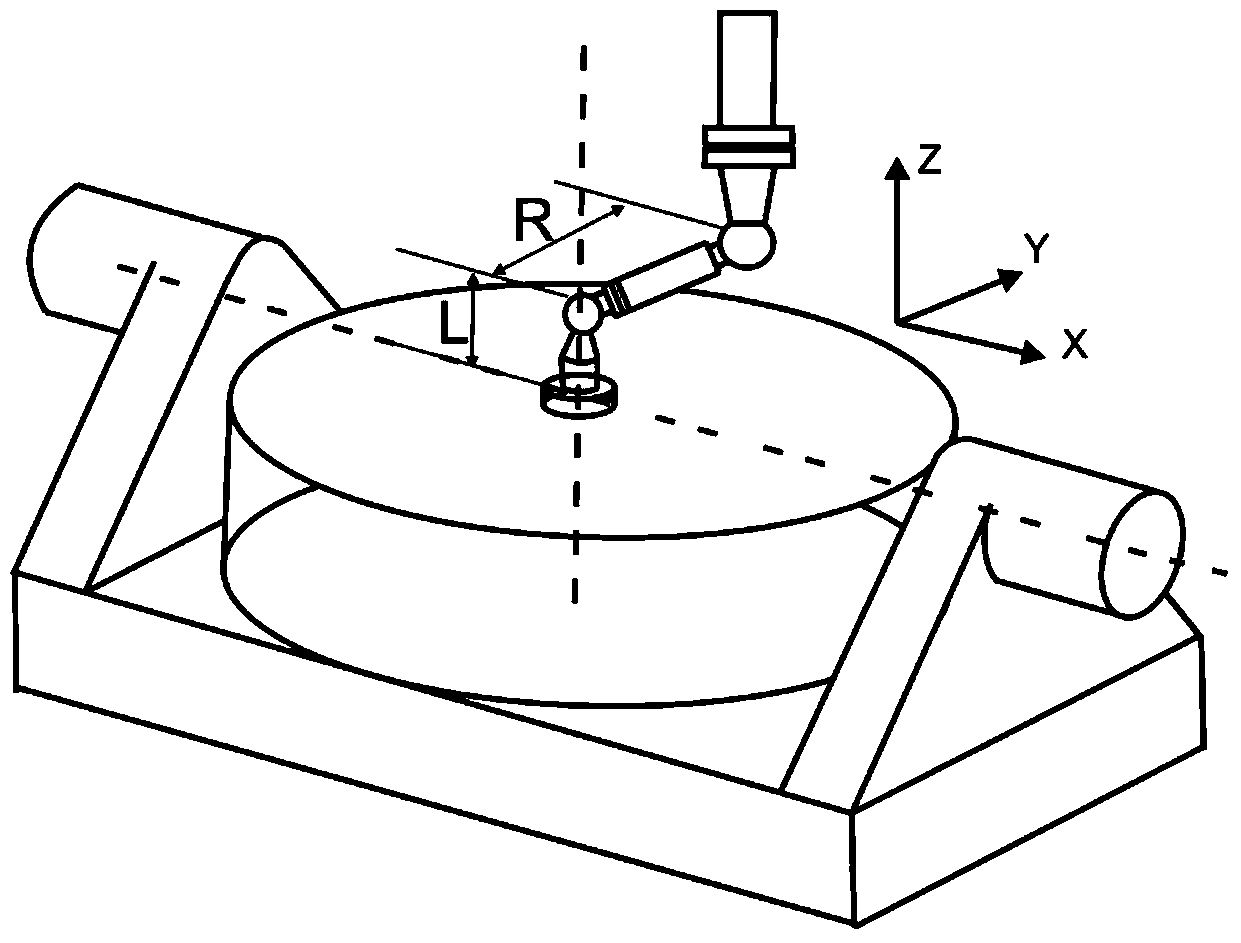

[0046] Step 1. According to the type of five-axis CNC machine tool, use the tracking function of the five-axis CNC machine tool to determine three installation modes for ballbar measurement:

[0047] Step 1.1. Determine that the two rotation axes of the five-axis CNC machine tool are A-axis and C-axis. In order to ensure that the ballbar is stationary relative to the measured rotation axis during ballbar measurement, use the tracking function of the machine tool t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com