Mud flushing roller washing machine

A technology of rollers and mud flushing, which is applied in the direction of vehicle exterior cleaning devices, etc., can solve the problems of high maintenance cost, troublesome processing and installation, and easy failure, and achieve the effect of convenient flushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

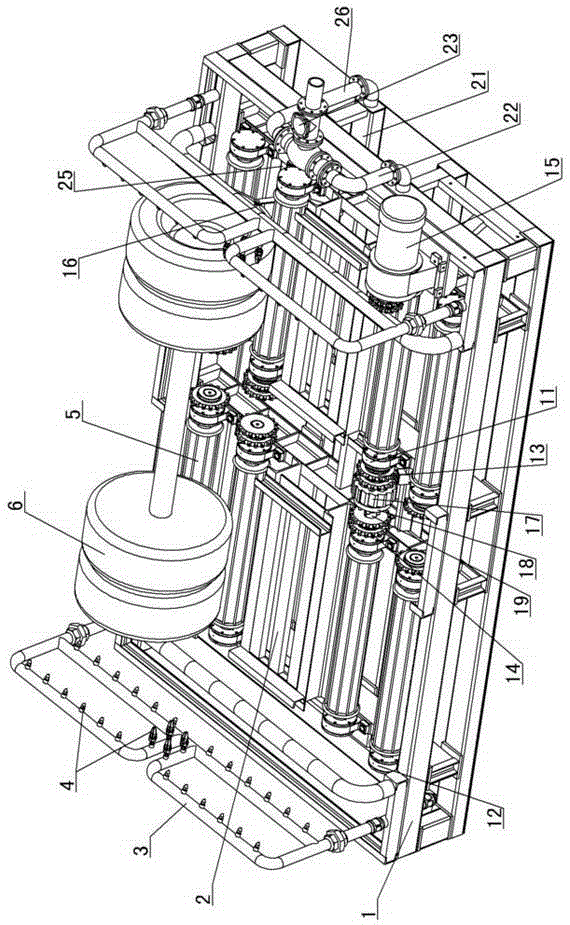

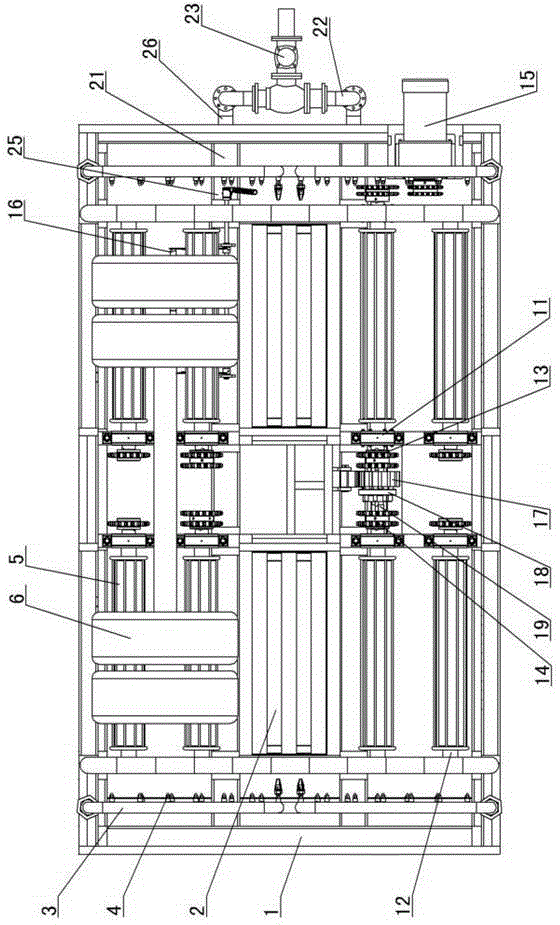

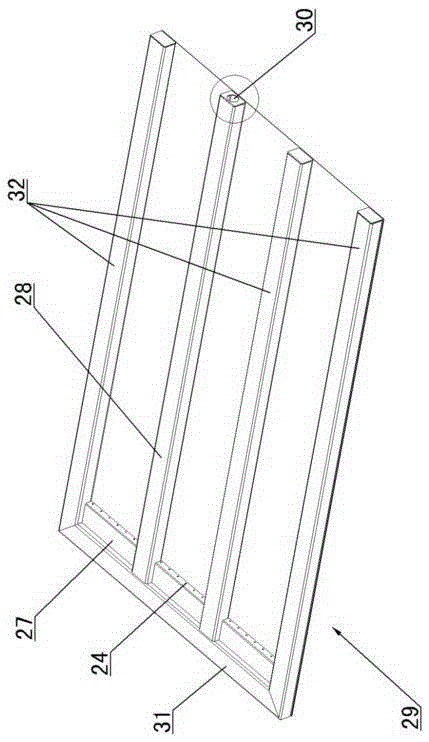

[0010] The invention relates to a mud flushing type roller washing machine, such as figure 1 — image 3 Shown, comprise the main frame 1 of washing machine, be provided with roller 5 and grille plate 2 on the main frame, be connected by chain between each roller 5, wheel 6 is pressed on the roller, and roller 5 is driven by roller The mechanism drives the rolling. The roller mechanism includes a driving roller assembly 11, a driven roller assembly 12 and a ratchet assembly. The driving roller sprocket 13 is installed on the driving roller assembly 11, and the driven roller assembly The driven roller sprocket 14 is installed on 12, the driving roller assembly 11 is driven by the motor through the reducer 15, and side water spray mechanisms are respectively set on both sides of the main frame 1, and the side water spray mechanisms include side spray Assembly 3, nozzle 4 is installed on the side spray assembly, mud flushing pipeline 21 is installed on the bottom of the main fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com