Double-water-conducting straight-drop type closestool

A straight-down toilet technology, applied in the field of living appliances, can solve the problems of inability to form a siphon, low momentum, high water consumption, etc., and achieve the effects of shortening flushing time, fast replacement speed, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

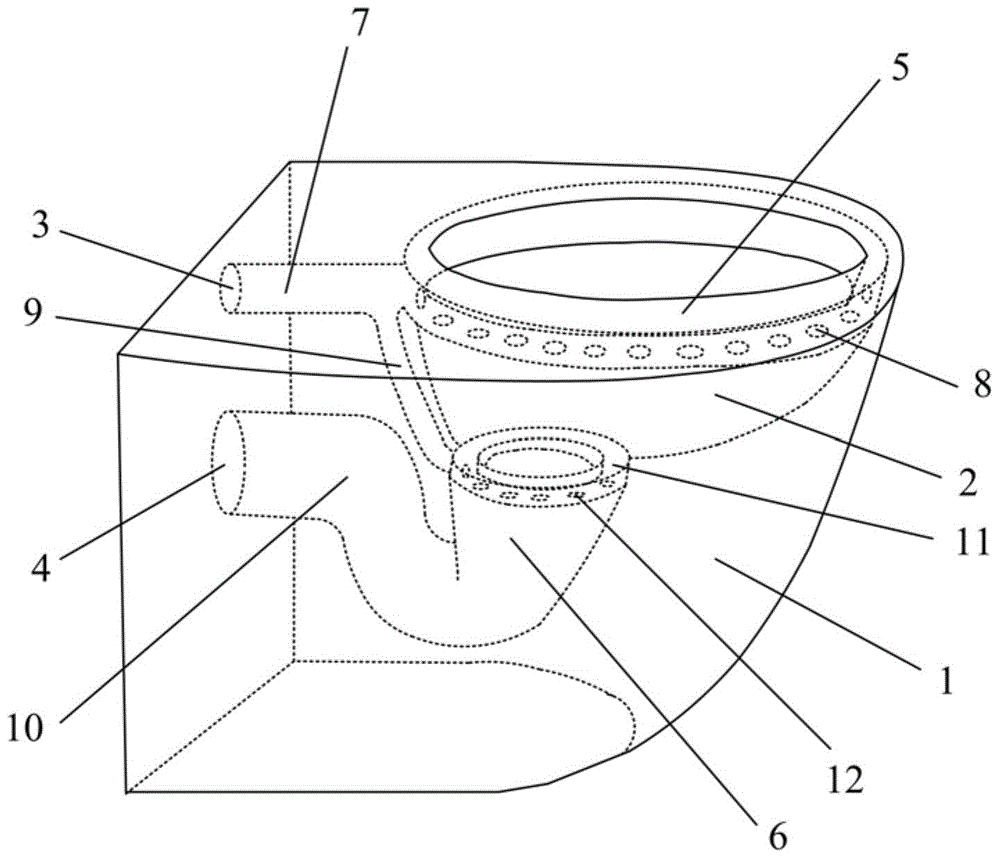

[0016] Such as figure 1 As shown, it is a structural schematic diagram of a double-guide straight-down toilet, which includes a toilet body 1 and a urinal 2, the toilet body 1 is provided with a water inlet 3 and a sewage outlet 4, and the upper part of the urinal 2 is provided with an upper water guide Circle 5, the bottom of the urinal 2 is connected with the sewage outlet 6, the water inlet 3 and the upper water guide ring 5 are connected through the main water pipe 7, and the lower end of the upper water guide ring 5 is provided with a plurality of washing holes 8 distributed along the circumferential direction; The double-guiding straight-fall toilet also includes an auxiliary flushing water pipe 9 and a sewage pipe 10. One end of the sewage pipe 10 is connected to the sewage outlet 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com