Composite cloth guide roller

A fabric guide roller and composite technology, which is applied in the direction of winding strips, processing textile material carriers, thin material processing, etc., can solve problems affecting product quality, fabric guide surface wear, and affect cloth flatness, etc., to improve convenience Improve the quality and detail, improve the quality, and ensure the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

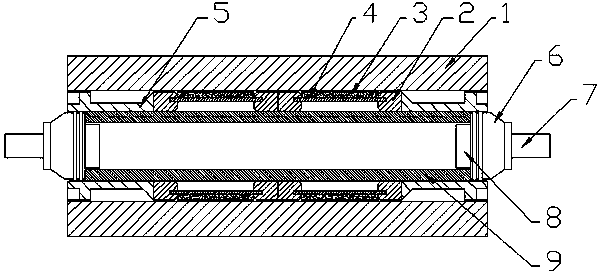

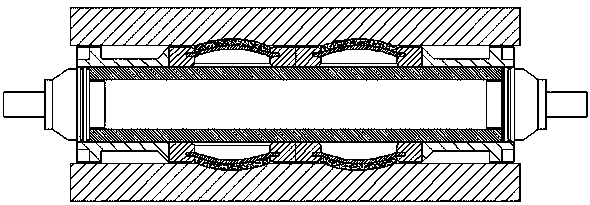

[0022] Further description will be given below in conjunction with the accompanying drawings

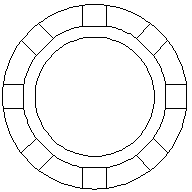

[0023] As shown in the cloth guide surface 1 and rubber 3, this product is a composite cloth guide roller. This product includes a rotating shaft and a cloth guiding surface 1 arranged outside the rotating shaft in contact with the cloth. The cloth guiding surface 1 and the rotating shaft A support mechanism is provided between them, the support mechanism includes two oppositely arranged collars 5, and two expansion rings arranged side by side between the collars 5, the expansion ring includes two fixed rings 2, and the two fixed rings 2 A bar-shaped spring piece 4 is arranged in a circular array on the opposite surface, and rubber 3 is arranged between the outer wall of the spring piece 4 and the inner wall of the cloth guide surface 1. The shaft includes a shaft 9 and a shaft head, and the shaft head It includes a fixed seat 6 and a connecting rod 7 vertically arranged at the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com