Winding drum support with adjustable width

An adjustable and reel technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of unfavorable metal wire for subsequent use, heavy reel weight, and easy failure of the cantilever, etc., to achieve the best use effect Good, low cost, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

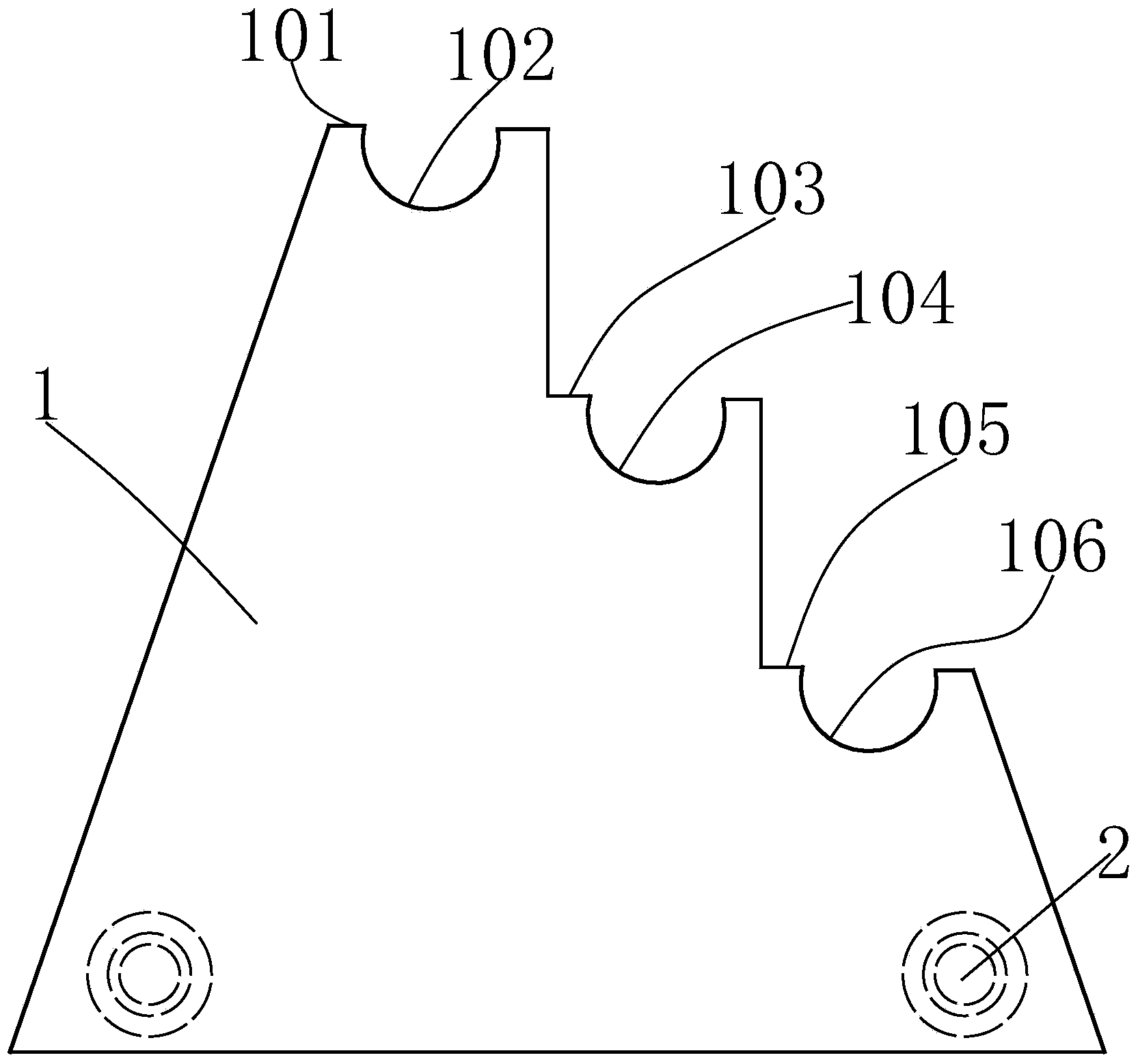

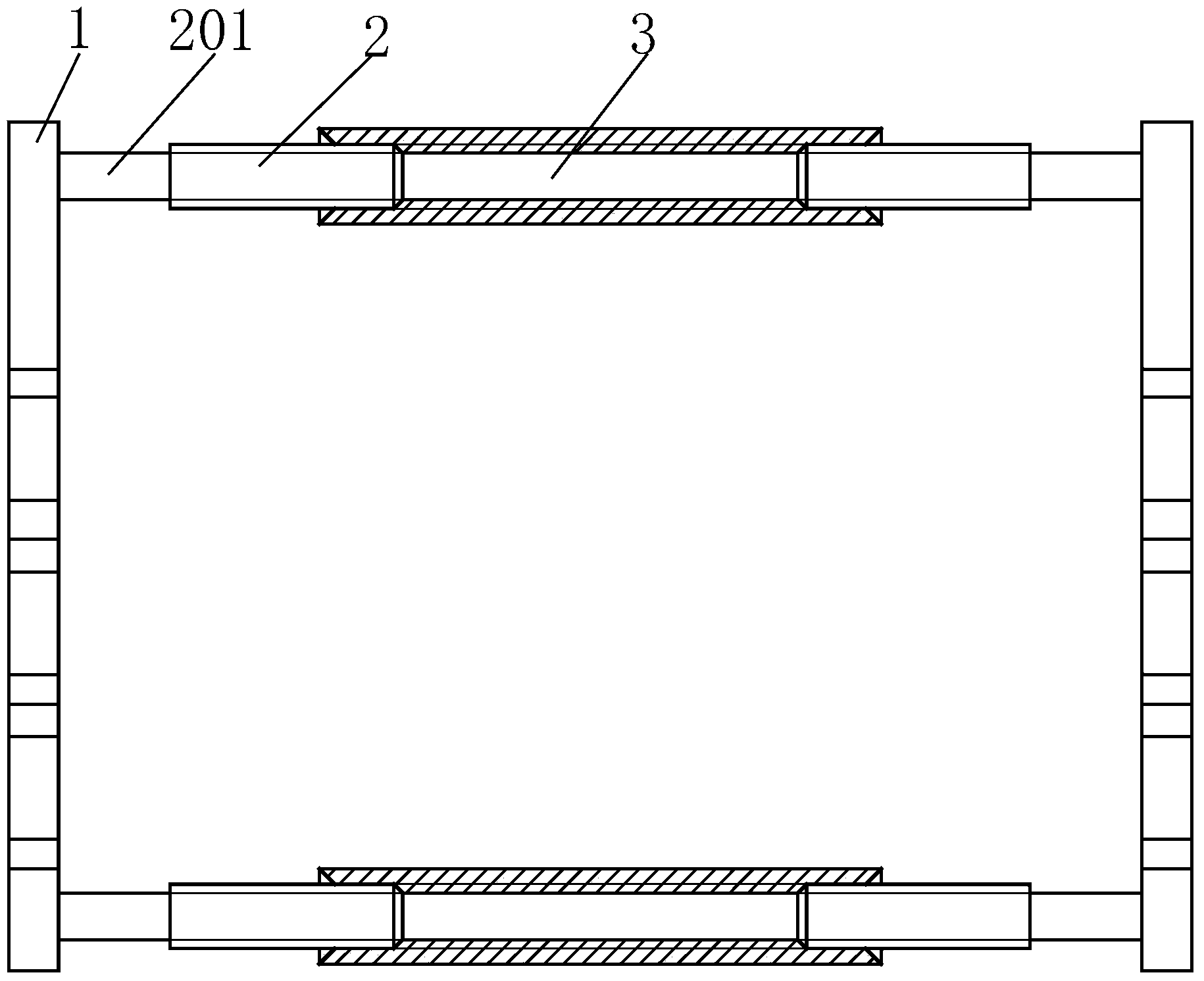

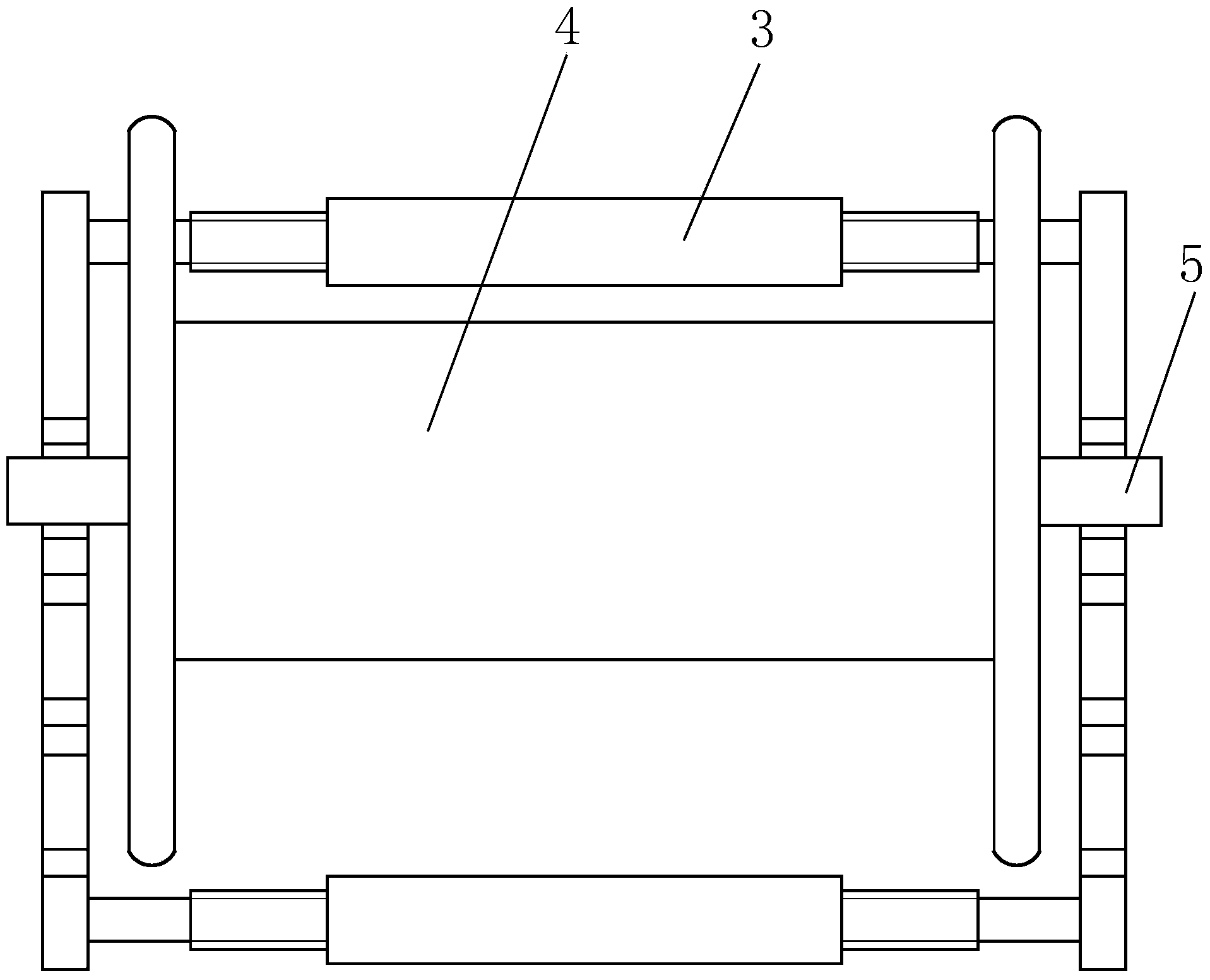

[0016] like Figure 1 to Figure 4 As shown, a width-adjustable reel support includes a side plate 1, the left and right sides of the side plate 1 are hypotenuses, and the upper end of the side plate 1 is provided with a stepped surface to target different diameters of the reel 4. Adopting different heights of step surfaces to support, it is beneficial to control the center of gravity of the reel 4 and improve the stability of the support; No. 1 arc groove 102 is provided on the No. 1 step 101 of the step surface, and No. 1 arc groove 102 is provided on the No. 2 step 103 of the step surface. No. two arc grooves 104 are arranged, and No. three arc grooves 106 are arranged on the third step 105 of the step face. Stability in the arc grooves. In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com