Whole blisk laser shock strengthening equipment

A technology of laser shock strengthening and integral blisk, which is applied in the field of laser shock strengthening equipment, can solve problems such as low production efficiency, immature production equipment, and difficult selection of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

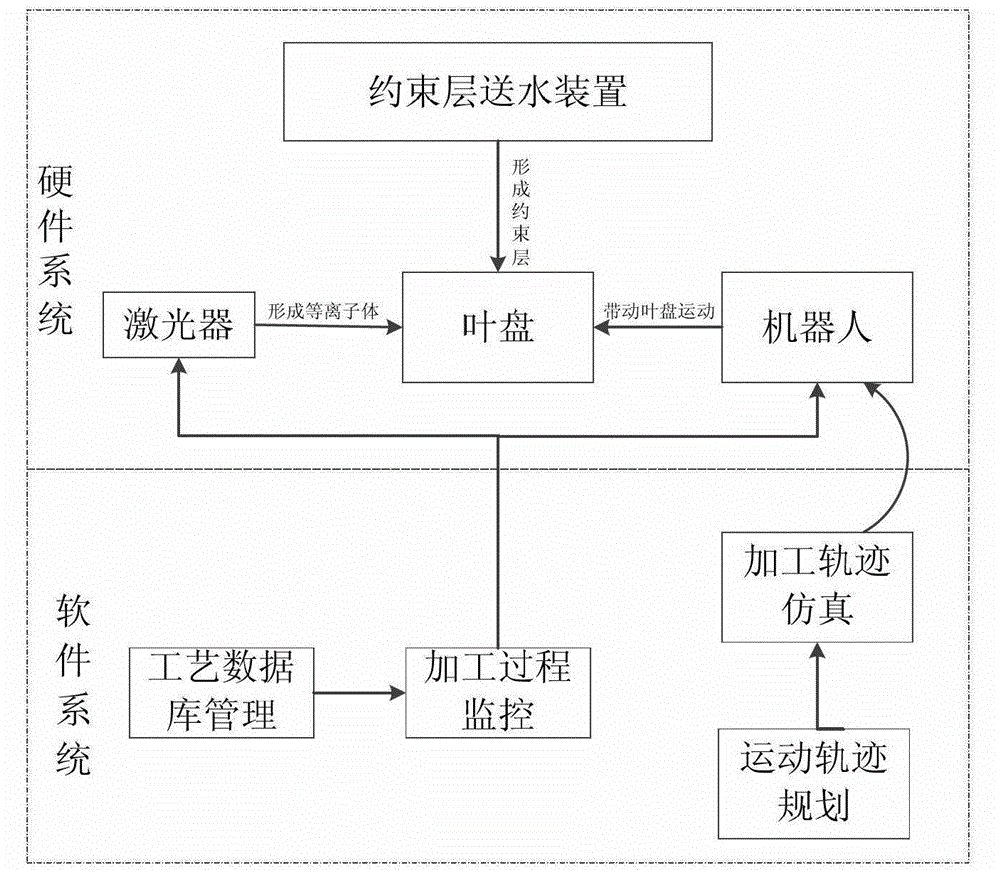

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be described in further detail below in conjunction with the accompanying drawings.

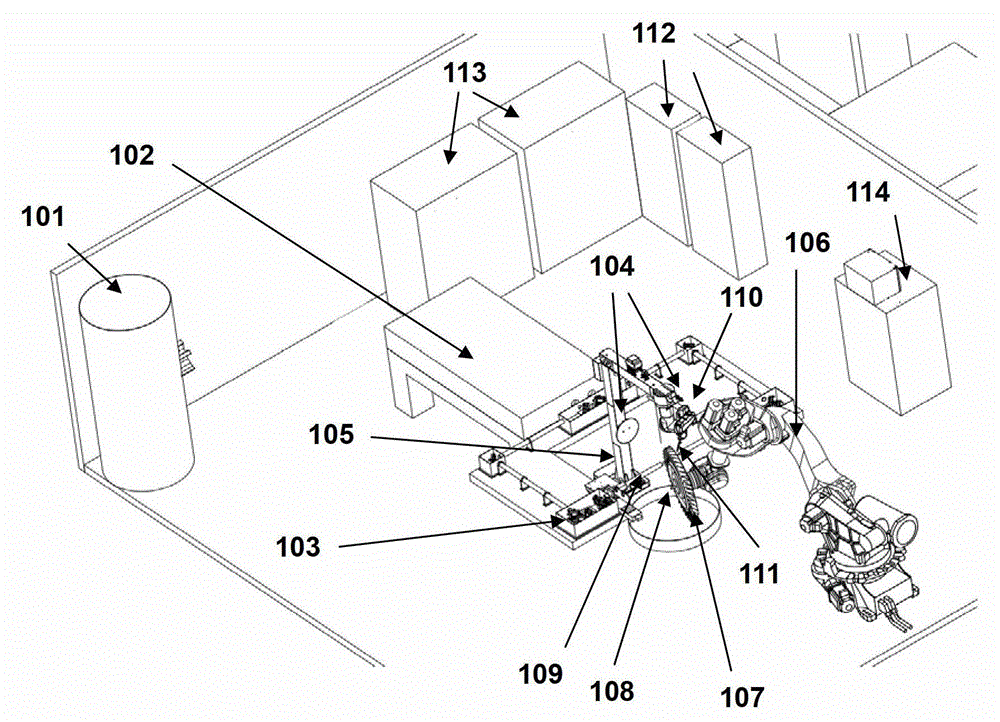

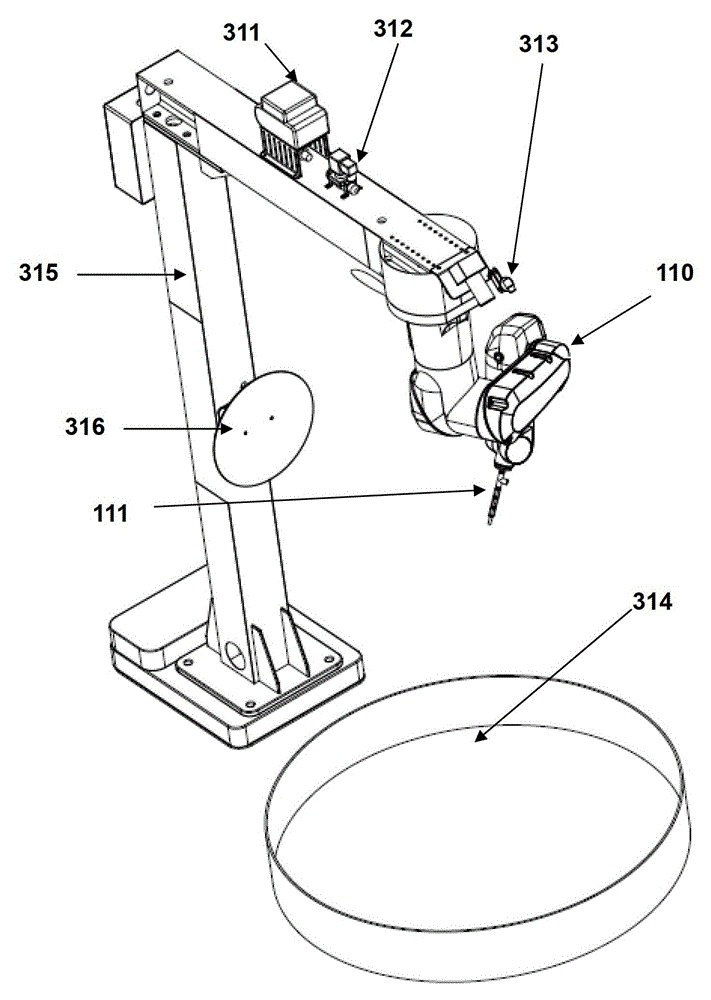

[0086] The structure and layout of the present invention are as figure 2 As shown, the water delivery system 101 is connected with the water delivery robot system 110 to deliver water to the processing area of the blisk 107 according to the specified direction and size; the laser beam emitted by the laser 102 is directly transmitted through the optical system 103 installed in front of the laser 102 to the processing area of the blisk 107 or transmitted to the processing area of the blisk 107 through the optical system 103 and the laser head 109, wherein the light outlet of the laser 102 is aligned with the light entrance of the optical system 103; the sound pressure quality monitoring system 316 is installed on the bracket 105 and at the same height as the blisk 107 processing area, it is used to monitor the processing quality of the blisk; the process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com