Kitchen ventilator and manufacturing method thereof

A technology for range hoods and manufacturing methods, which is applied in the fields of oil fume removal, heating methods, household heating, etc., and can solve the problems of raising manufacturing costs and unfavorable sharing of components of range hoods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

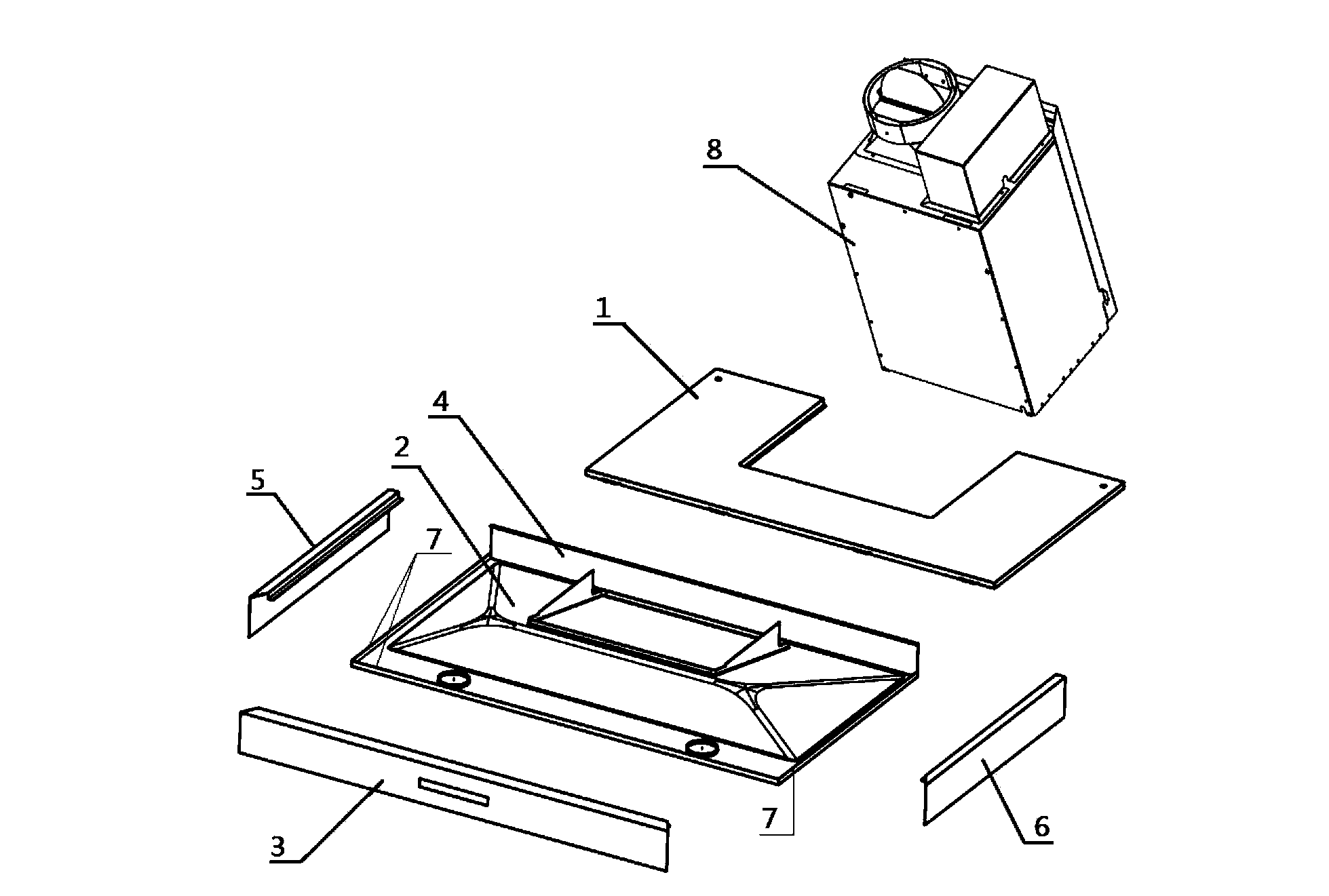

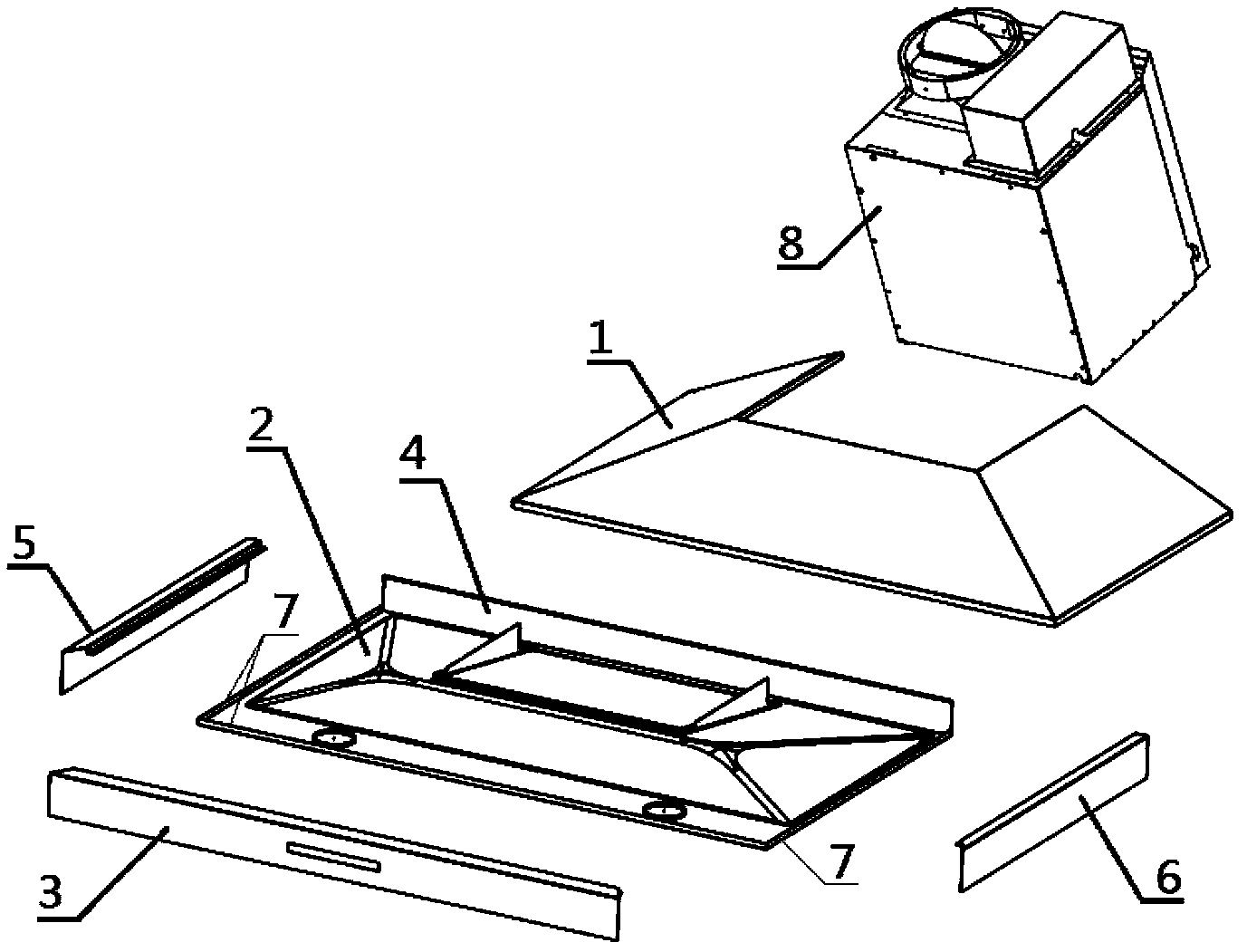

[0035] A kind of range hood embodiment that the present invention proposes, such as figure 1 As shown, the range hood includes a housing and a fan system 8 . The housing comprises an inner cover 2 and side wall elements connected to the inner cover 2 . The inner housing 2 is a first module M1 of the cooker hood, which is provided with a first connecting element for connecting with a side wall element. The so-called "inner cover 2 is the first module M1 of the range hood" means that the inner cover 2 is an independent component of the range hood, and the inner cover 2 is assembled with other related components of the range hood after being manufactured. The inner cover 2 itself adopts an integrally formed structure, and in addition, the inner cover 2 also includes a rear side wall element 4 . The fan system 8 is connected with the inner cover 2 .

[0036] The side wall element is the second module M2 of the cooker hood. The so-called "the side wall element is the second mod...

Embodiment 2

[0043] The present invention also proposes a method for manufacturing the above-mentioned range hood embodiment, and the structure of the range hood will not be repeated here, please refer to the relevant description of Embodiment 1.

[0044] The manufacturing method embodiment of this cooker hood comprises the following steps:

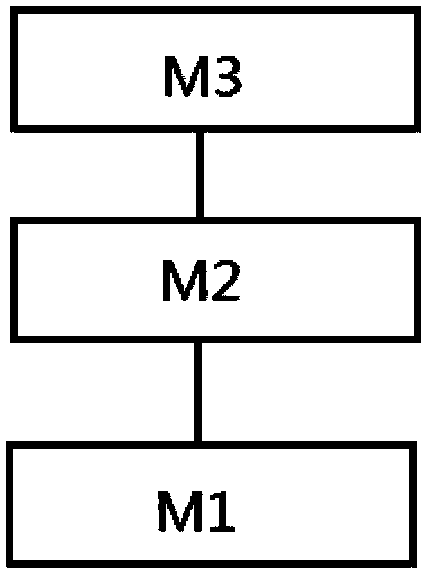

[0045] Manufacture a first module M1 and at least two optional and different second modules M2, specifically, the first module M1 is manufactured using an integral molding process; from at least two optional and different second modules M2 Select a second module M2 from the module M2; connect the first connecting element of the first module M1 with the second connecting element of the selected second module M2, specifically, weld the first The module M1 is connected with the second module M2; further, the welding position is polished until a seamless structure is presented;

[0046] manufacturing at least two alternative and different third modules M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com