Diameter measurement ruler

A caliper ruler and a technology for measuring diameter, which is applied in the field of caliper rulers, can solve problems such as the inability to measure the inner diameter of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

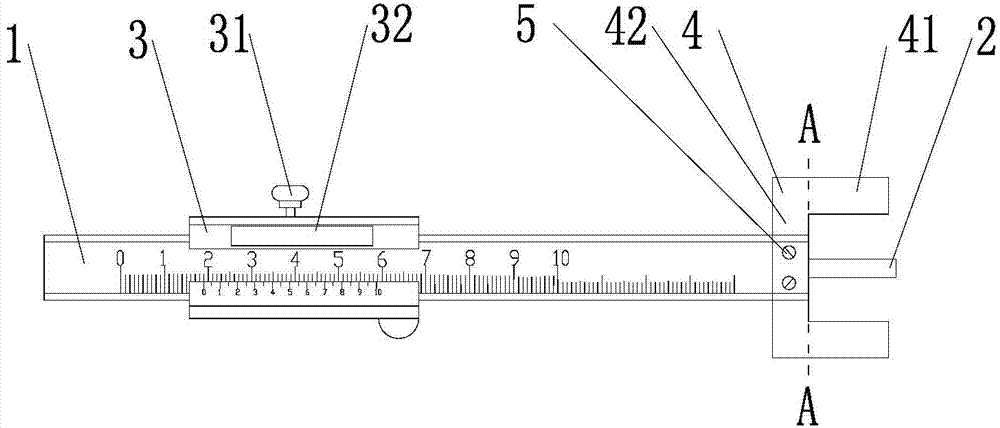

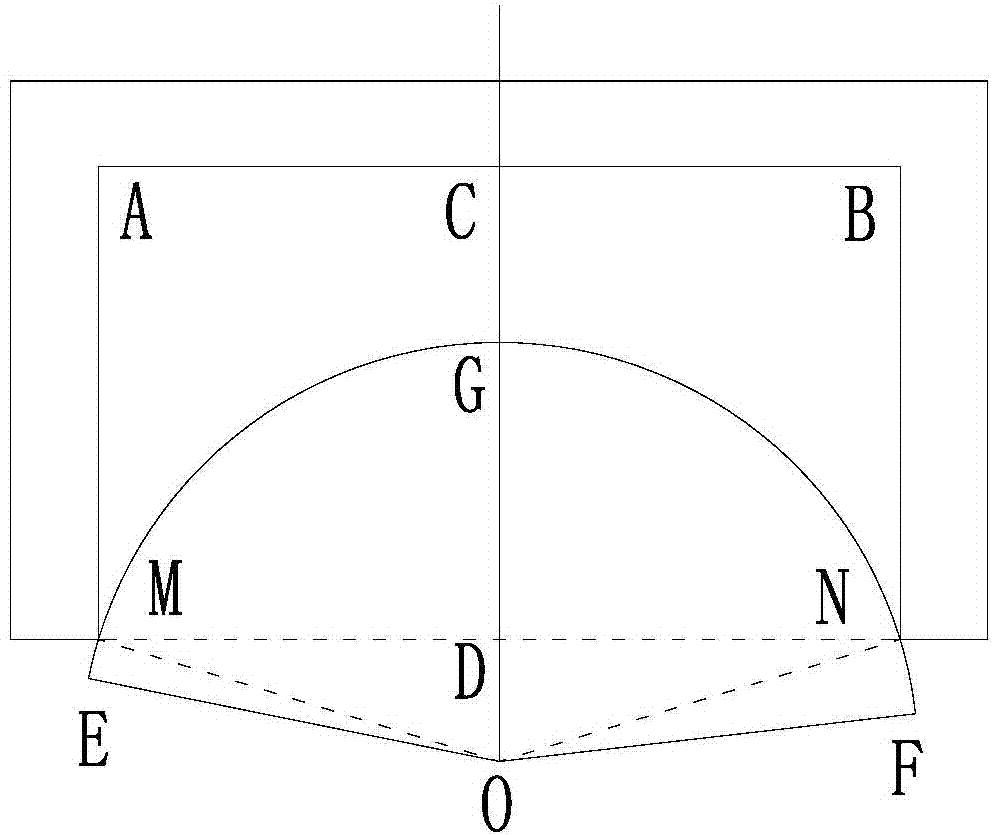

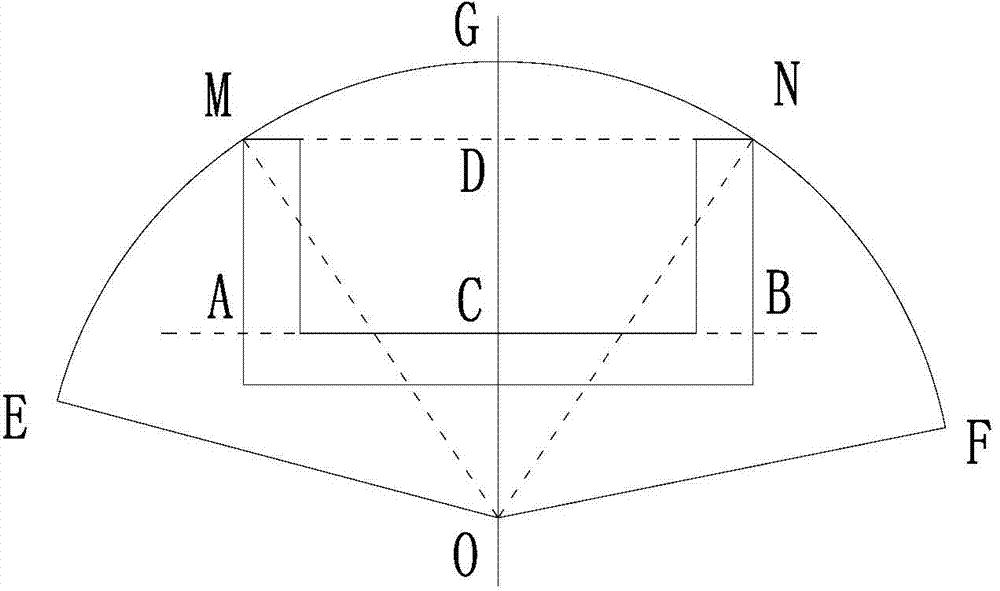

[0032] The caliper structure of the present embodiment is as figure 1 As shown, it includes a scale body 1, a moving ruler 2 arranged in the scale body 1 and parallel to the scale body 1, and a vernier 3 arranged on the scale body 1 and able to slide along the length direction of the scale body 1. The moving ruler 2 can also be According to actual needs, it is arranged on the interlayer, back or side of the ruler body 1. One end of the movable ruler 2 is connected to the vernier 3 in a manner that can move synchronously, and the other end is suspended in the air. The specific linking method of the movable ruler 2 and the vernier 3 can be selected according to needs. If a fixed link is adopted, the vernier 3 and the moving ruler 2 can also be directly designed as an integrated one, and the moving ruler 2 can also slide along the length direction of the ruler body 1 . The cursor 3 is also provided with a fastening screw 31 for fixing the position of the cursor 3 and a digital di...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that the shape of the claw 41 on the caliper block 4 is different, and the shape of the caliper block 4 of the present embodiment is as follows Figure 4 As shown, the jaws 41 arranged on the caliper block 4 are needle point-shaped jaws, and the distance between the two jaws 41 is the distance between the sharp points of the two jaws. Use the caliper of this embodiment to measure the outside diameter and inner diameter, the contact points of the jaws 41 and the arc of the workpiece to be measured are all on the sharp point of the jaws 41, so the scale value of the diameter scale does not need to mark the outer diameter and the inner diameter separately. The principle of the caliper of the present embodiment is the same as that of Embodiment 1.

Embodiment 3

[0038] The difference between this embodiment and Embodiment 1 is that there are two caliper blocks 4, which are used to measure the outer diameter and the inner diameter respectively, and different caliper blocks 4 can be replaced according to needs during use. The shape of the measuring block 4 used to measure the outer diameter is as Figure 5 As shown, the shape of the measuring block 4 used to measure the inner diameter is as follows Image 6 As shown, all are knife-shaped claws, and the distance between the two claws 41 is the distance between the sharp points of the two claws. The principle of the caliper of the present embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com