Method for detecting photoresist damage using dark field silicon wafer inspection machine

A technology for detecting light and detectors, applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve problems such as time-consuming and labor-intensive, inability to accurately reflect the degree of photoresist damage in real time, and avoid production losses , damage prevention, the effect of real-time scanning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

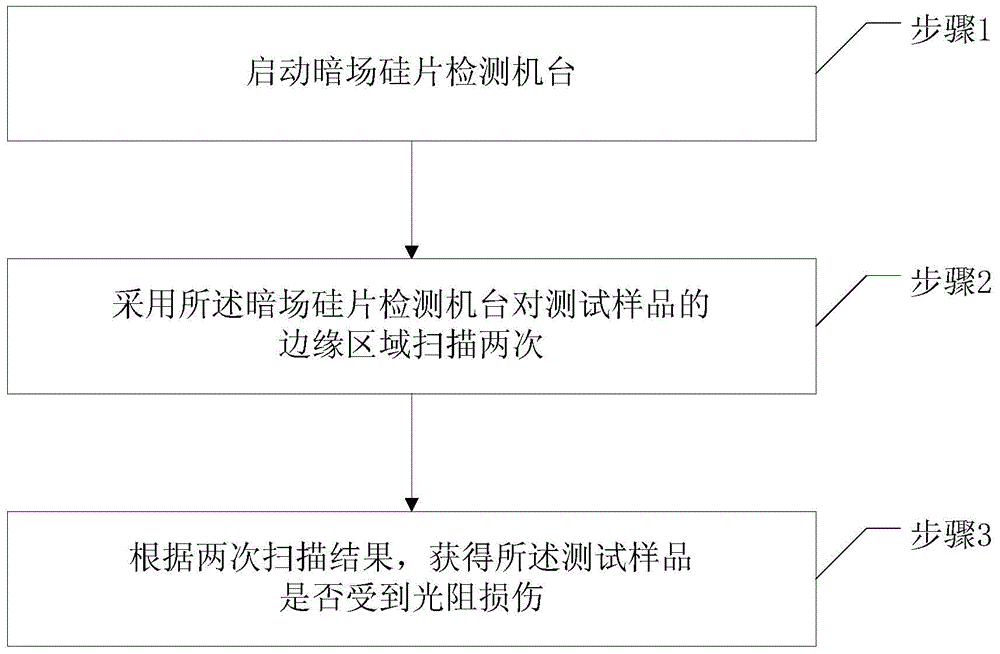

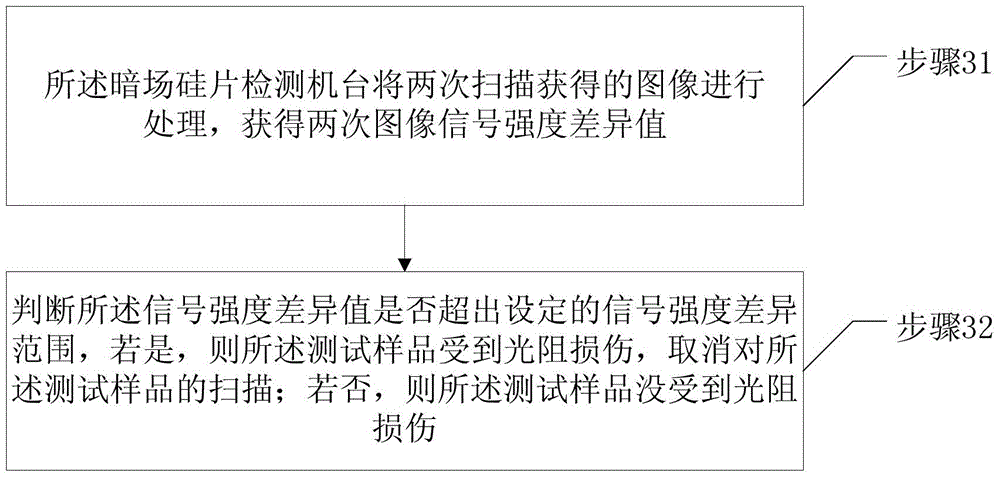

[0030] like figure 1 and figure 2 As shown, the present invention provides a method for detecting photoresist damage using a dark-field silicon wafer detection machine, comprising the following steps:

[0031] Step 1. The user first sets the scanning program of the dark field wafer inspection machine according to the relevant parameters of the sample to be tested (wafer with photoresist), and starts the dark field wafer inspection machine;

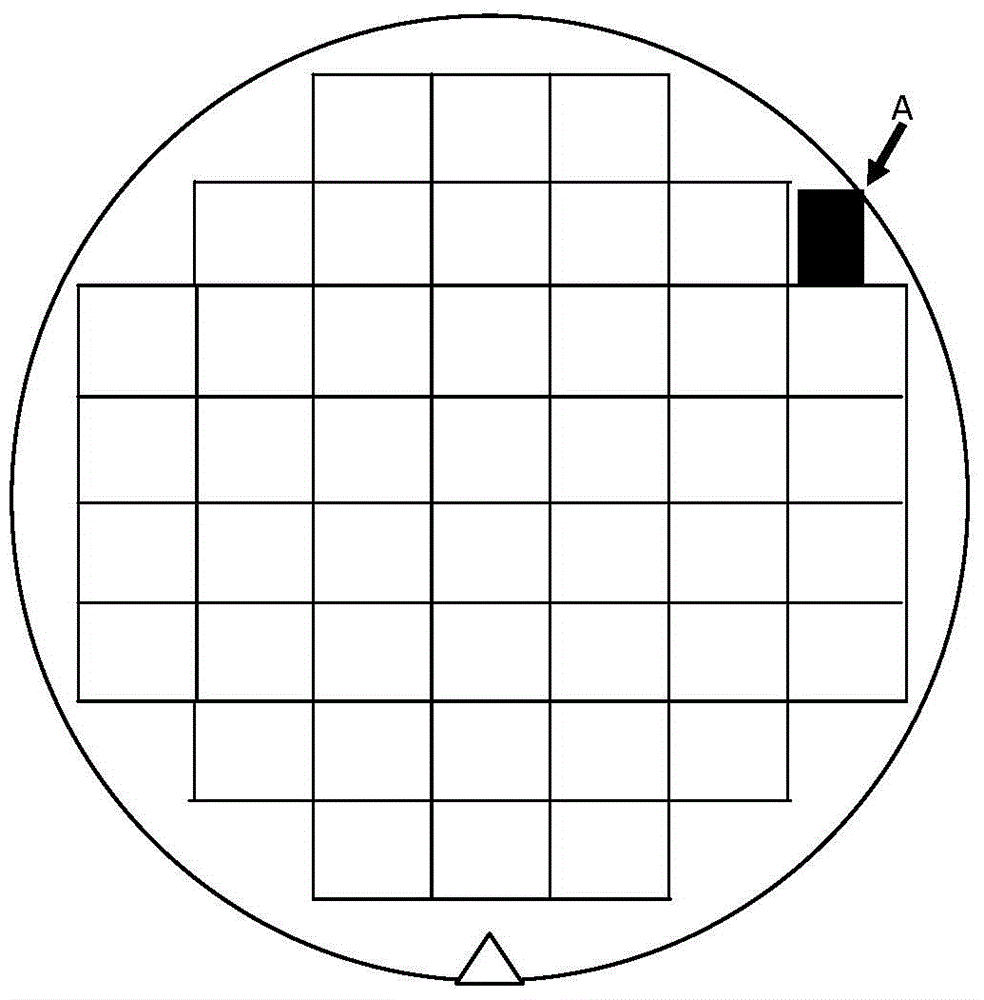

[0032] Step 2. Use the dark field silicon wafer detection machine to test the edge area A of the sample (such as Figure 3 to Figure 5 Shown) scan twice, the edge area of the test sample is selected because the incomplete product does not affect the yield rate, and it can ensure that if the photoresist damage is caused to the test sample during the dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com