Ceramic refractory plug

A technology for refractory plugs and ceramics, applied in the field of ceramic refractory plugs, can solve the second problem that cannot be solved, can not reduce abrasion and other problems, and achieve the effects of avoiding condensation, avoiding clogging, and high gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

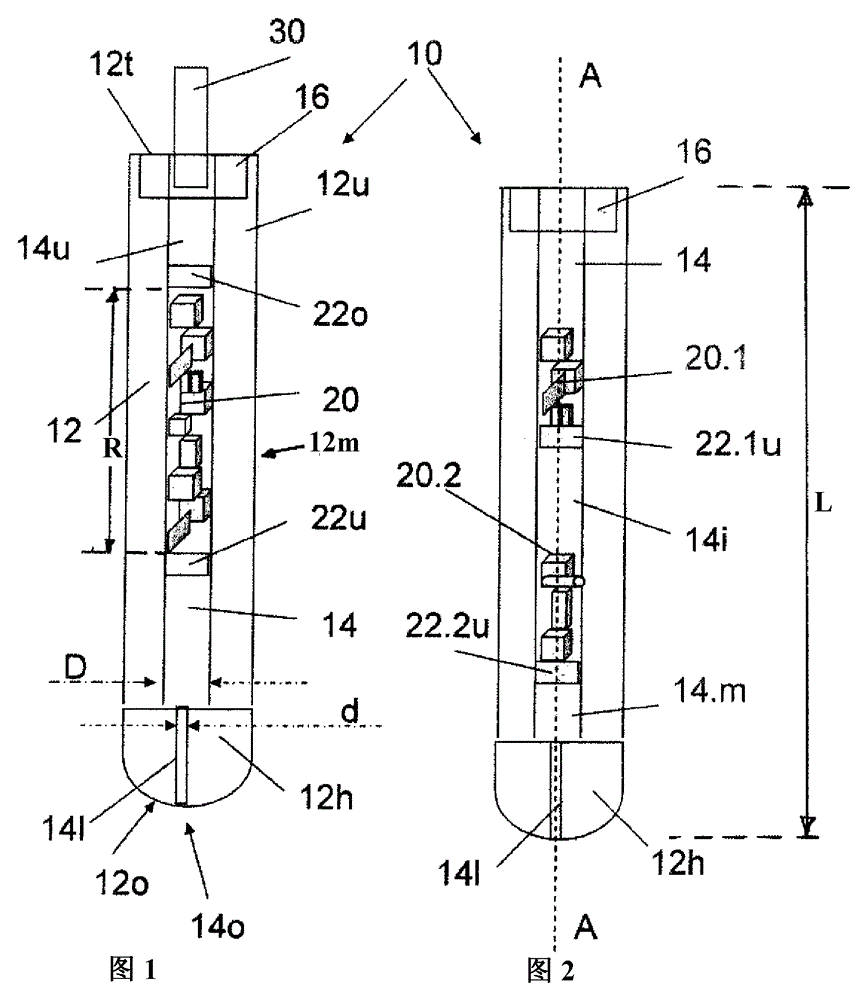

[0068] Figure 1 shows a longitudinal cross-section of a stopper rod 10 according to the invention in its working position. According to the prior art, it is made of a refractory ceramic plug body 12 shaped as a rod, comprising a substantially cylindrical main section 12m (in FIG. 1 , the upper section) and a head at its lower end. Section 12h, Head The section 12h is typically called the plug head.

[0069] The rod-shaped plug body 12 defines a central longitudinal plug axis ( figure 2 ), and includes a cylindrical gas channel 14, which extends concentrically with respect to the axis A from the upper end 12u of the plug body 12 to the plug head 12h in the plug body 12 (thus defining an inner diameter D The upper section 14u of the cylindrical gas channel 14), and extends into the plug head 12h and finally extends into the free outer surface area 12o of the plug 12h (thereby defining a cylindrical gas channel with an inner diameter d 14 lower section 14l).

[0070] At its up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com