A space-saving automatic flip fixture

An automatic flipping and space-saving technology, applied in clamping, clamping devices, manufacturing tools, etc., can solve the problems of low processing efficiency, urgent application of functional fixtures, pinch damage, etc., to improve processing efficiency, simple structure, and avoid clamping The effect of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

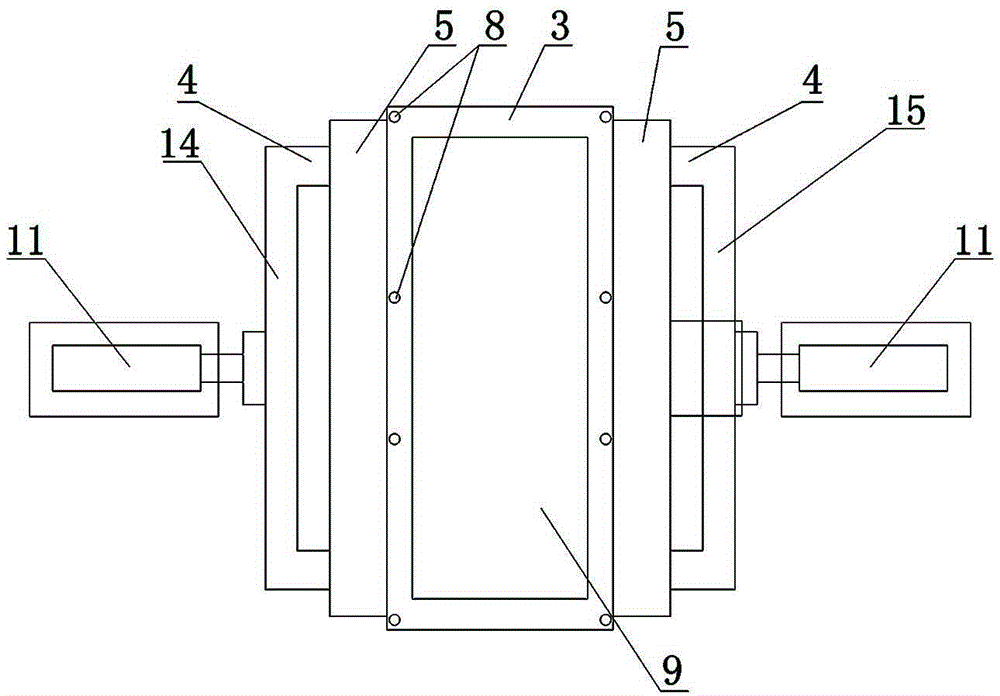

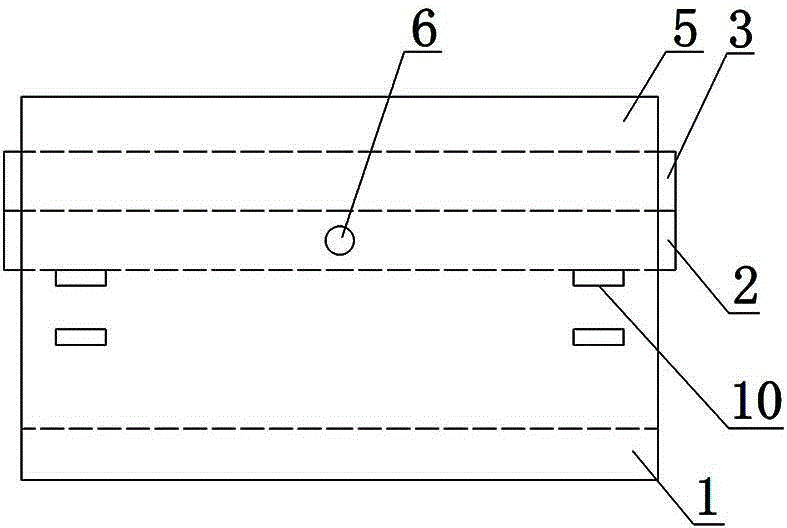

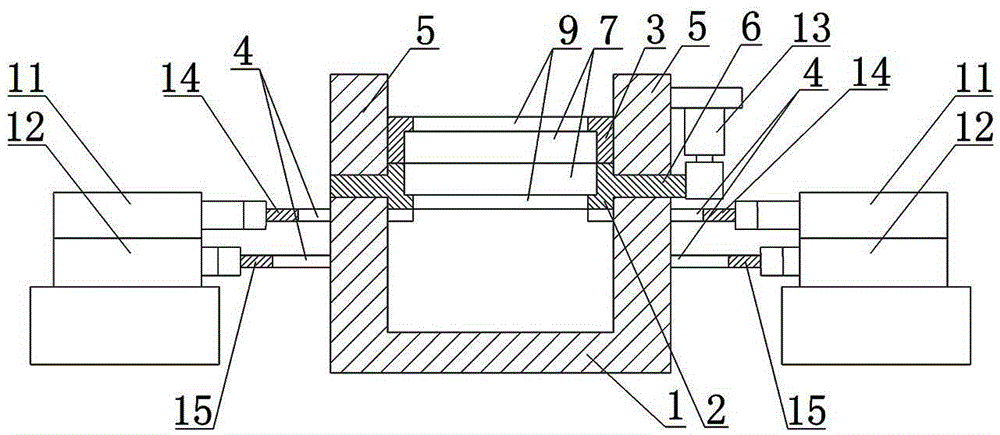

[0014] like figure 1 , image 3 As shown, a space-saving automatic flip fixture, it includes a support base 1, a flip frame 2, a compression frame 3, a support plate 4, an upper drive cylinder 11, a lower drive cylinder 12 and a rotary motor 13, such as figure 2 As shown, the upper part of the support base 1 is provided with two parallel support plates 5, the overturn frame 2 is arranged between the two support plates 5, and a rotating shaft 6 is provided on the edge of the overturn frame 2 close to the two support plates 5 , the two supporting plates 5 are provided with a shaft hole that matches the rotating shaft 6, and the two rotating shafts 6 on the overturning frame 2 are all rotatably installed in the shaft holes of the supporting plate 5 on the corresponding side, and the upper surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com