Grinding device for head portion and two side faces of screwdriver cutter bar

A technology of leveling and tool bar, applied in the direction of grinding machine, manufacturing tool, grinding feed movement, etc., can solve the problems of increasing the working time of workers and lowering work efficiency, and achieves the effect of high work efficiency and burr removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

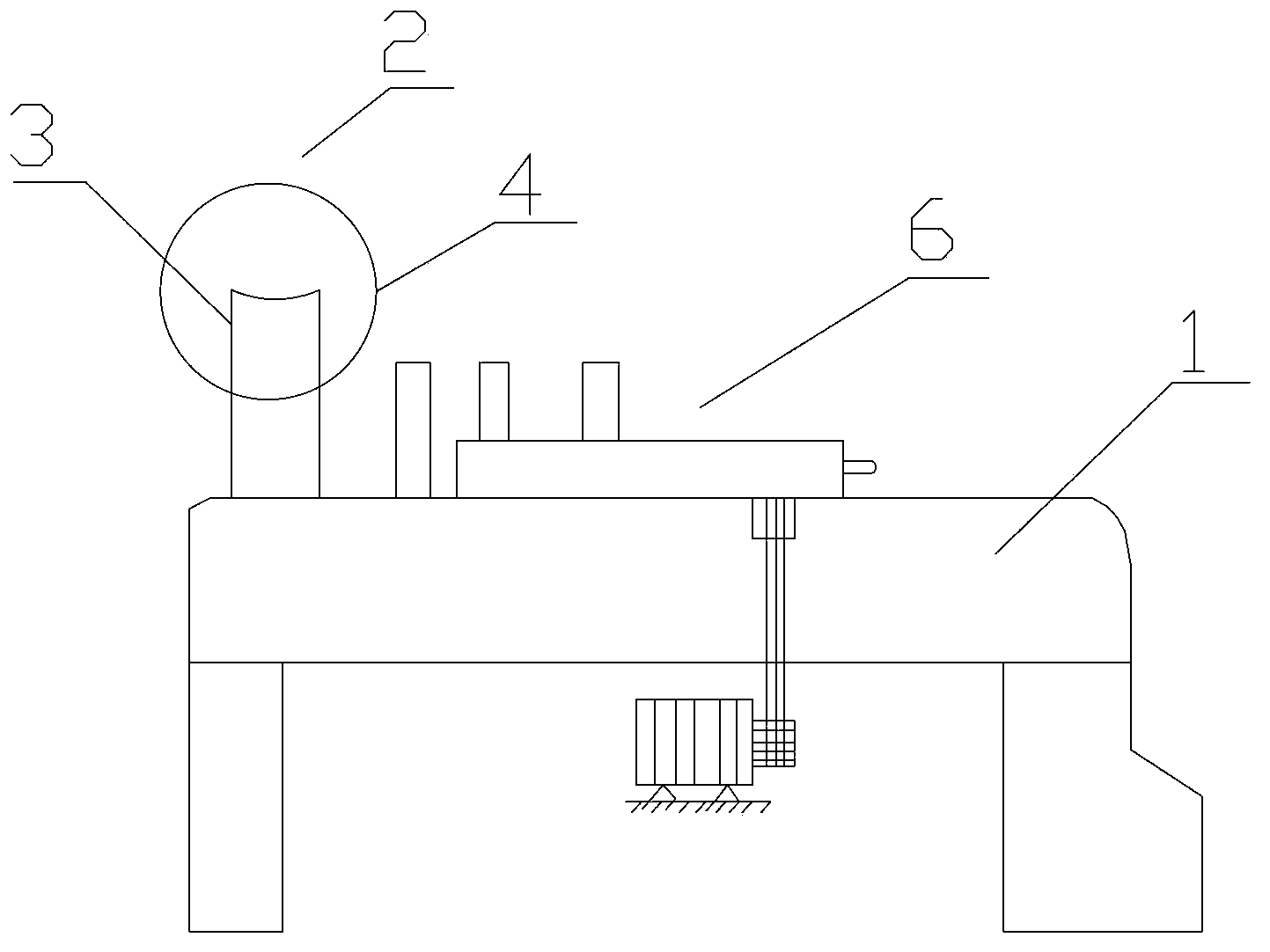

[0016] Example 1, such as figure 1 , figure 2 As shown, the grinding mechanism 2 includes a connecting rod 3 hinged on the support 1 and an electric grinding wheel 4 installed on the connecting rod. Corresponding to the manipulator 68, when it is necessary to process and polish the head of the knife bar, the manipulator 68 of the feeding mechanism clamps the knife bar, and drives the knife bar close to the working surface of the electric grinding wheel 4 through the first servo motor 64 and the second servo motor 66 Grinding the head of the shank.

Embodiment 2

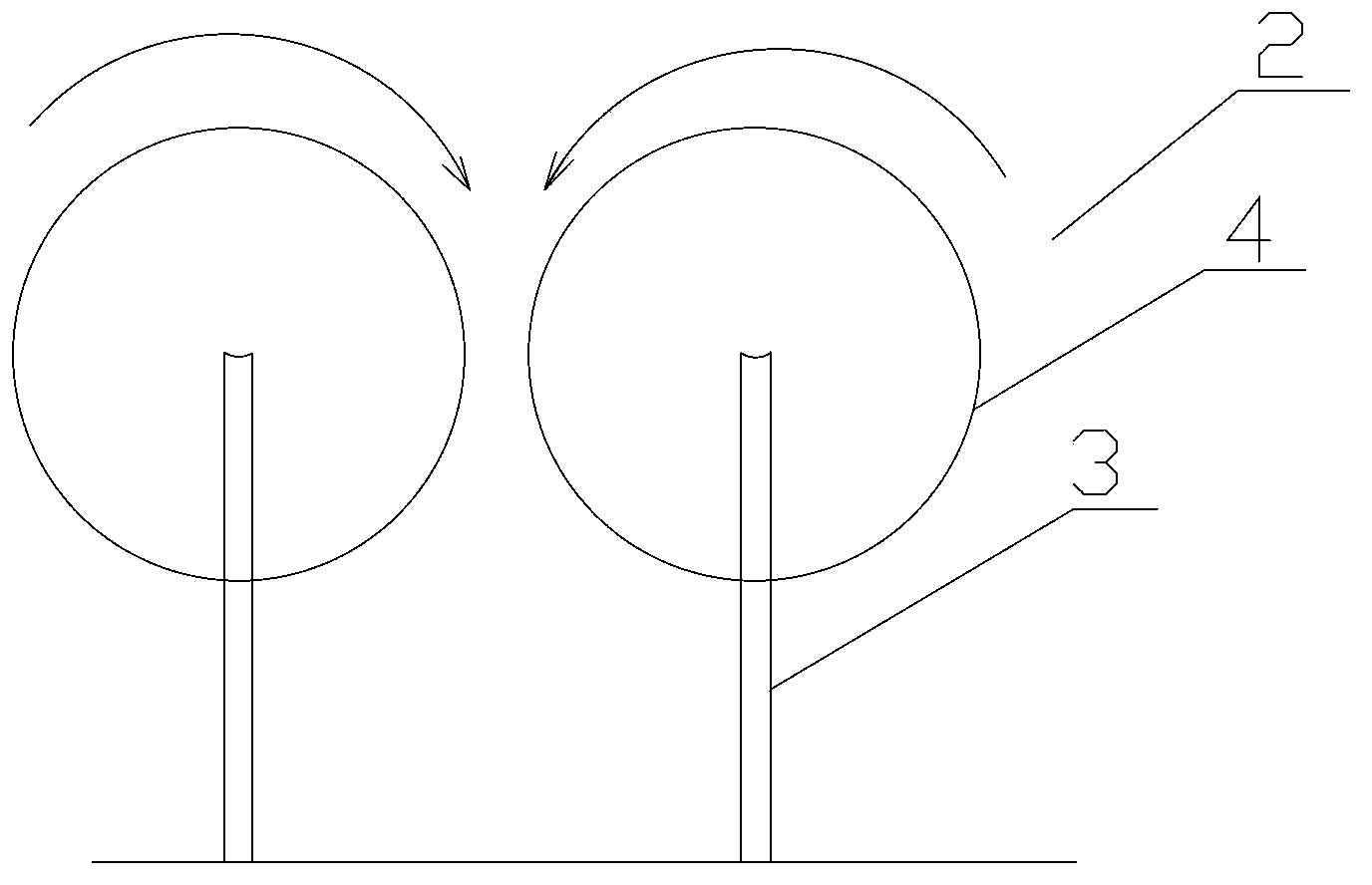

[0017] Example 2, such as image 3 As shown, the grinding mechanism 2 includes a connecting rod 3 hinged on the support 1 and an electric grinding wheel 4 mounted on the connecting rod. The number of the electric grinding wheels 4 is two, and the axes of the two electric grinding wheels 4 are parallel to each other. The working surfaces of the grinding wheels are opposite to each other with a gap left, and the direction of rotation is opposite. When it is necessary to process and polish both sides of the tool bar head, the tool bar is clamped by the manipulator 68 of the feeding mechanism 6, and passes through the first servo motor 64 and the second servo motor. Two servo motors 66 drive the knife bar close to the electric grinding wheel 4, and the knife bar is stretched into the gap between the two electric grinding wheels 4, and the two sides of the knife bar are polished by the electric grinding wheels 4 rotating in opposite directions.

[0018] The device adopts different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com