Main shaft self-locking mechanism

A spindle and self-locking technology, applied in the direction of portable motorized devices, manufacturing tools, etc., can solve the problems of high friction noise and small self-locking torque, and achieve the effect of large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

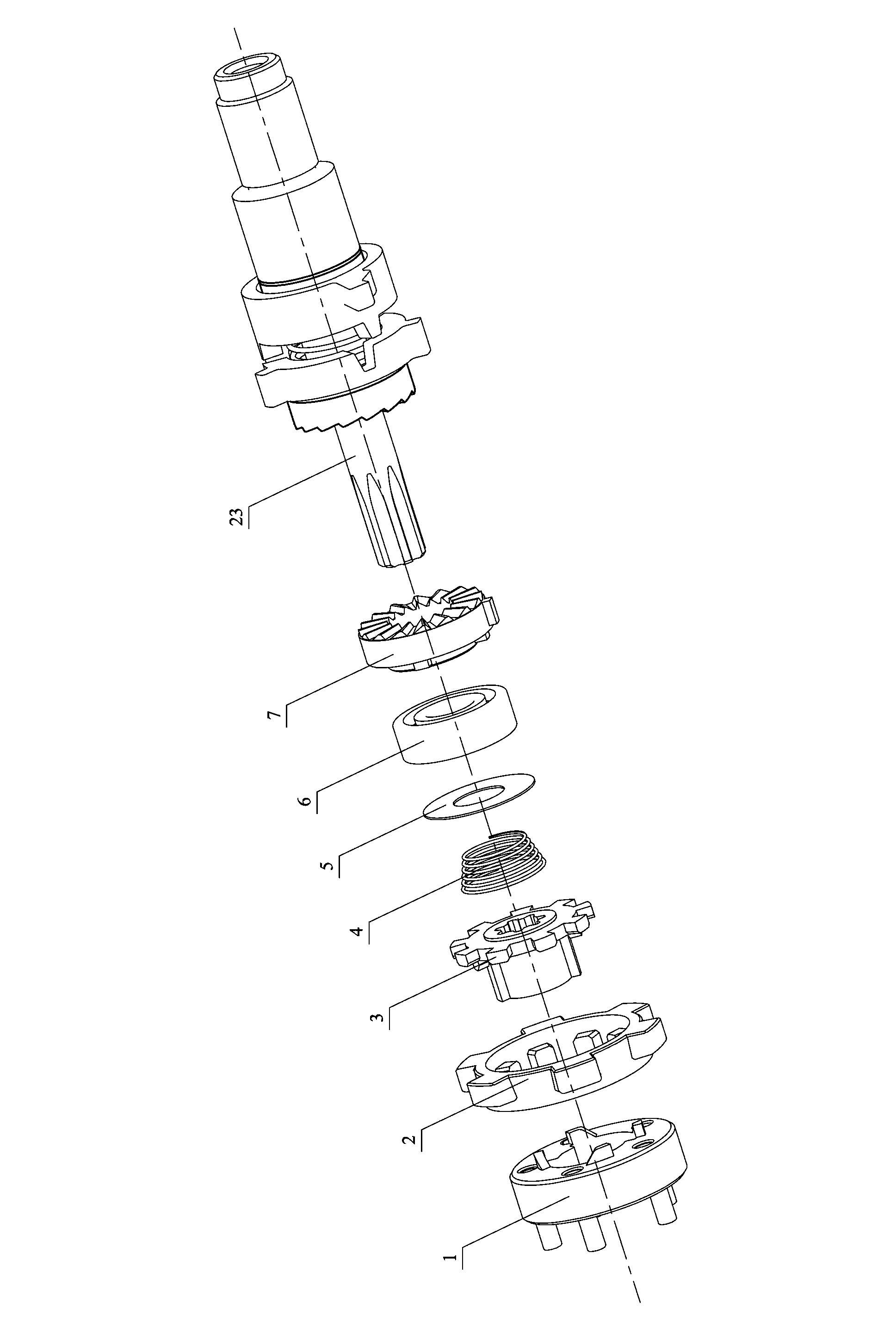

[0035] Embodiment one: see attached figure 1 to attach Figure 4 shown. A main shaft self-locking mechanism, which is connected with the main shaft 23 to realize the self-locking function for the main shaft 23 .

[0036] The spindle self-locking mechanism includes a planet carrier 1 , a fixed plate 2 , an adapter plate 3 , and a compression spring 4 .

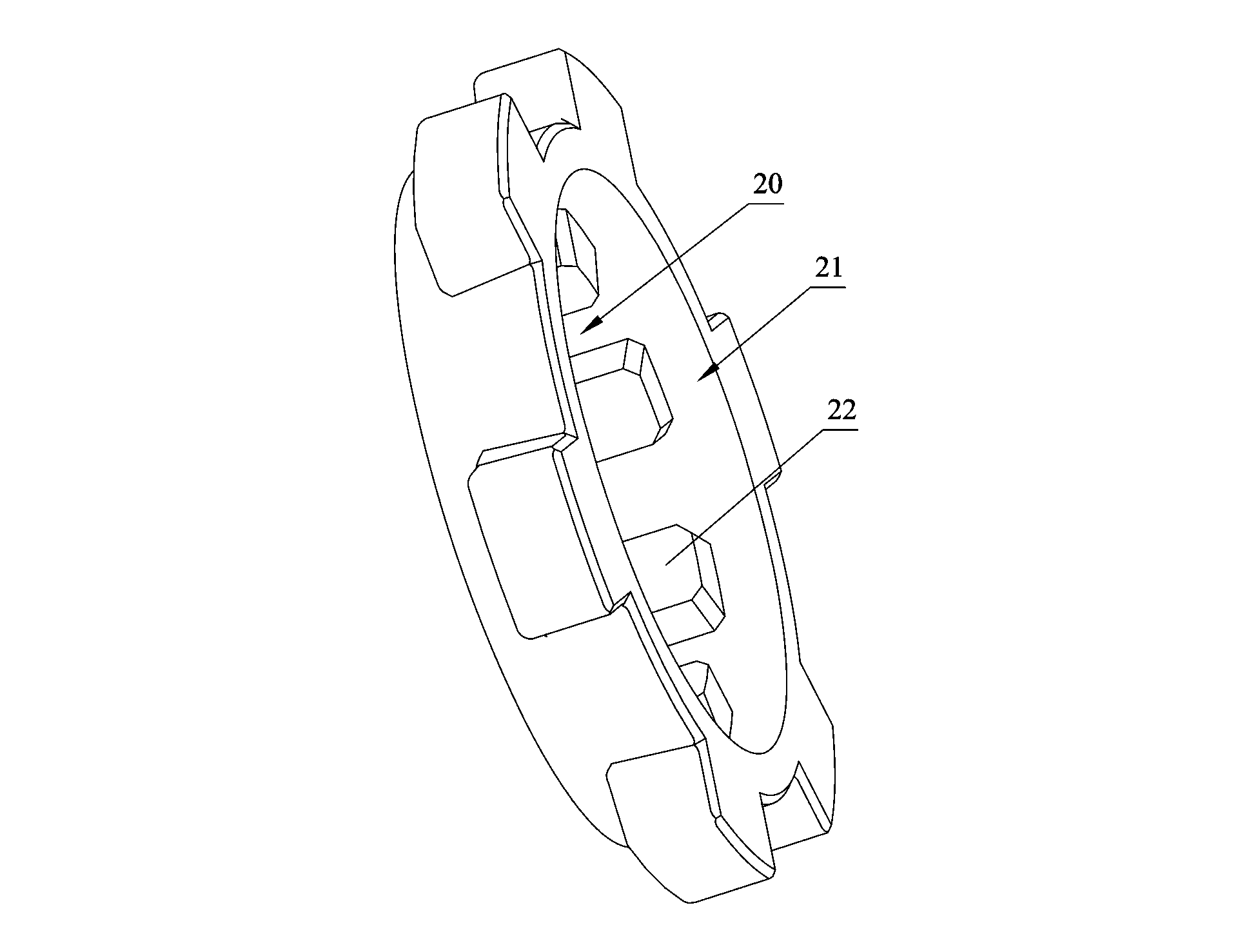

[0037] The adapter plate 3 and the main shaft 23 are fixedly connected by splines and rotate coaxially. A gasket 5 is provided between the adapter plate 3 and the compression spring 4 , and the main shaft 23 is provided with a bearing 6 and a static end tooth 7 . It is defined that the main shaft 23, the static end teeth 7, and the bearing 6 together form the collet 8.

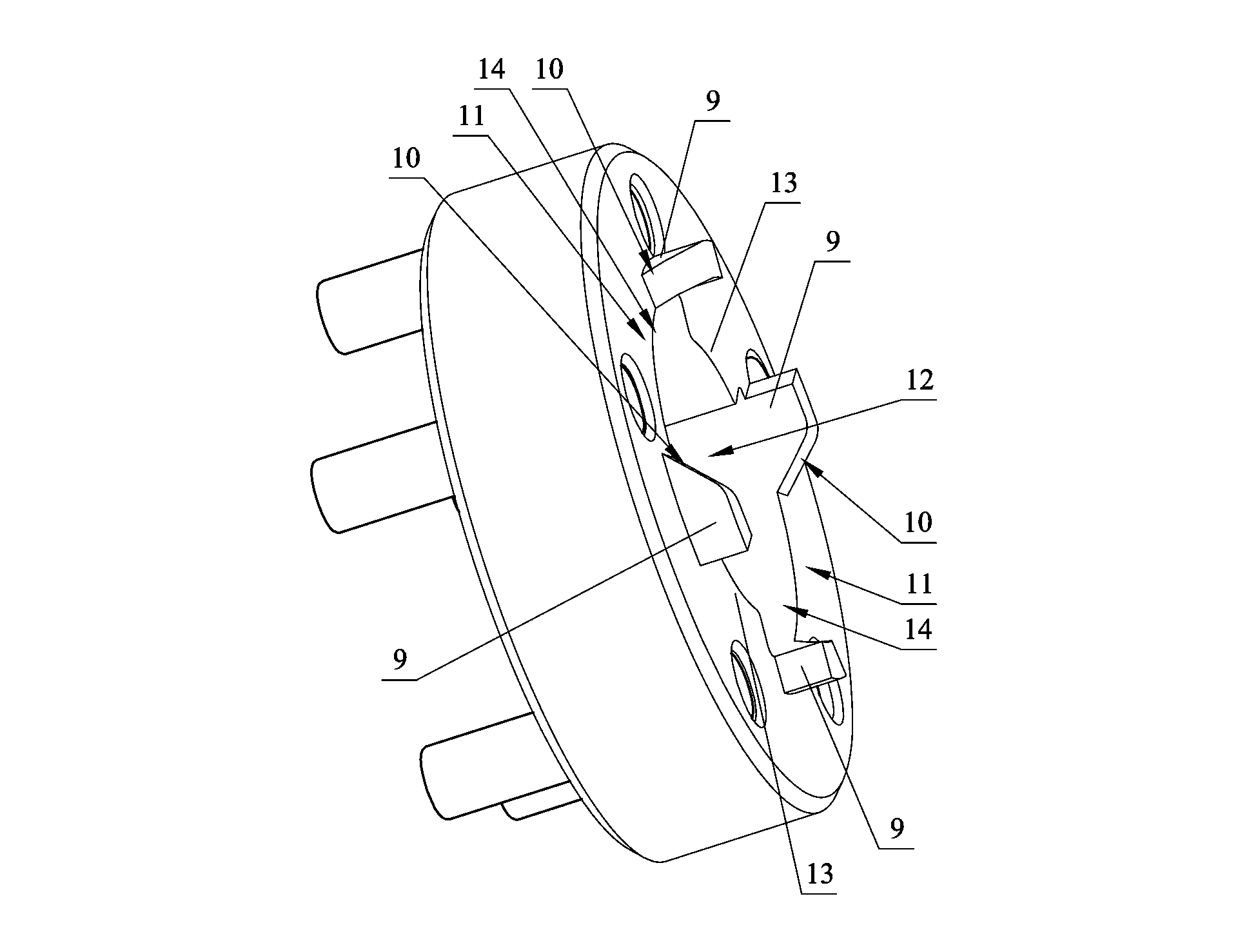

[0038] The planetary carrier 1 is coaxially connected with the adapter disc 3 . At least one pair of first bosses 9 are provided on the end surface of the planet carrier 1 near the adapter plate 3 . A pair of first bosses 9 are symmetrically arranged along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com