Side-frame vehicle body and assembly method thereof

A car body and frame technology, applied in the field of side girder frame car body and its assembly, can solve the problems of overall model modification and high manufacturing cost of new models, and achieve the goal of increasing manufacturing speed, saving manufacturing cost and reducing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

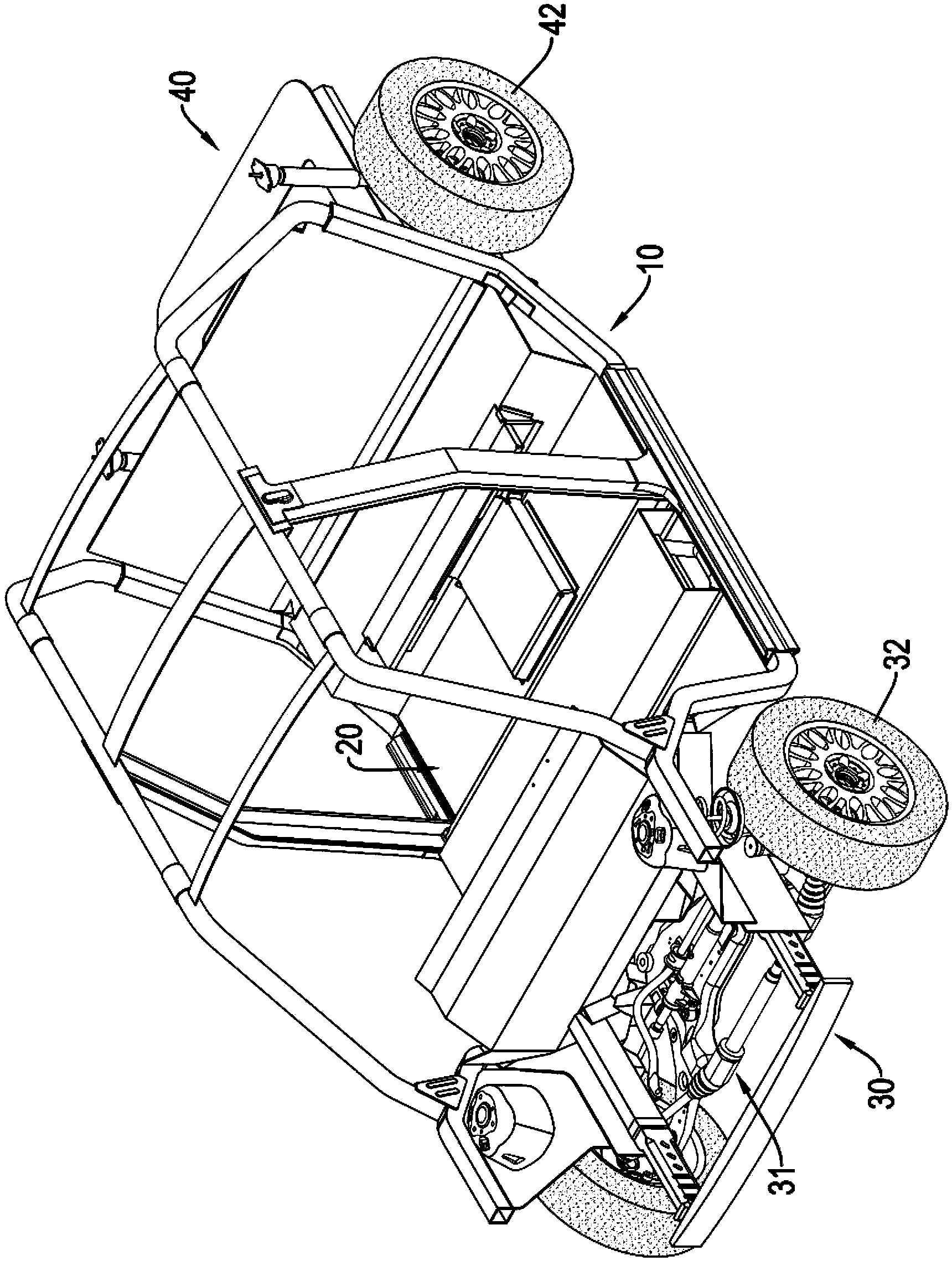

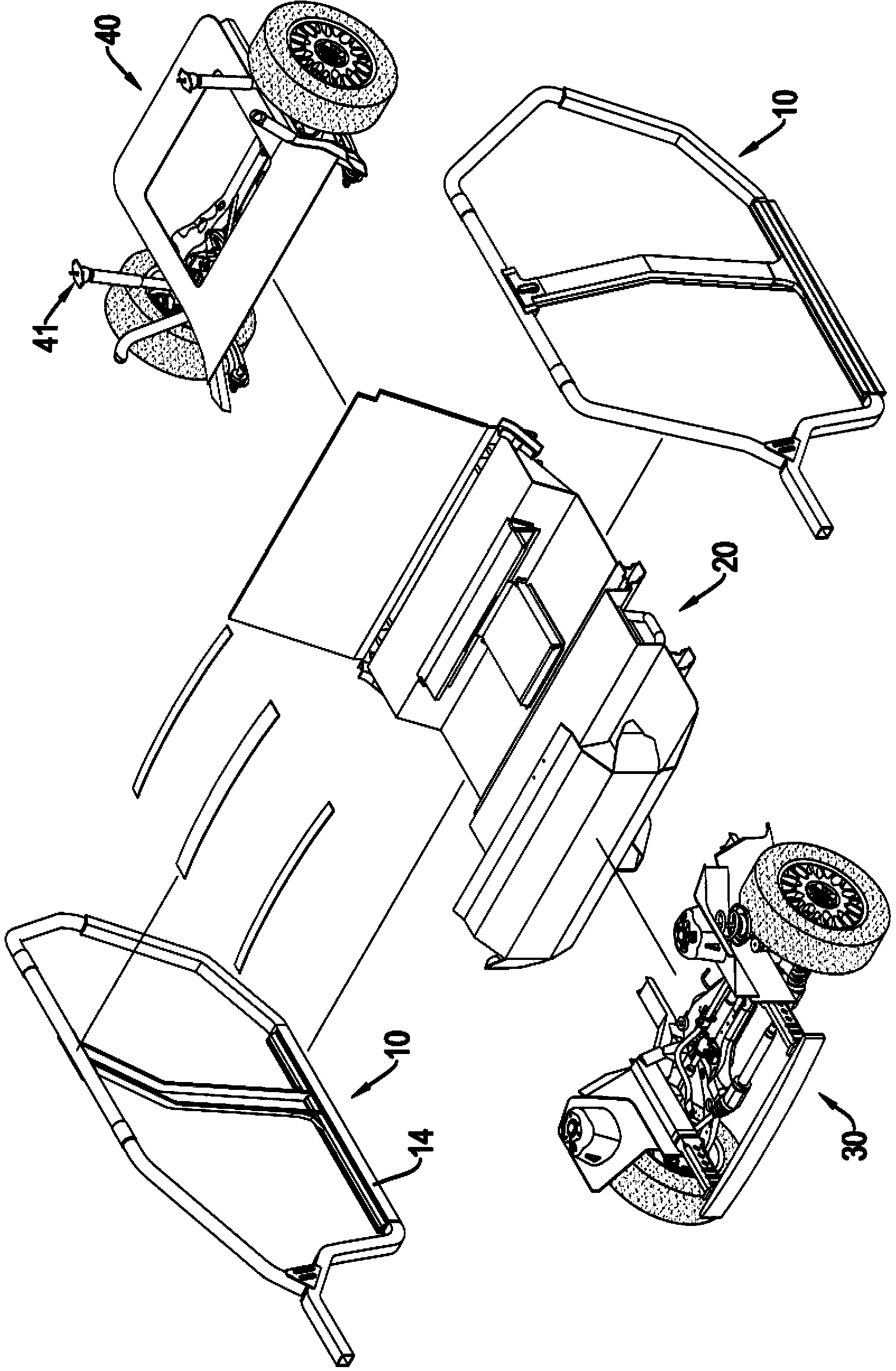

[0052] The present invention provides a side girder frame car body, which integrates the advantages of three car manufacturing concepts: Unibody, Body-on-frame and Space Frame. designed surface into, such as Figure 1 to Figure 4 The first preferred embodiment shown includes:

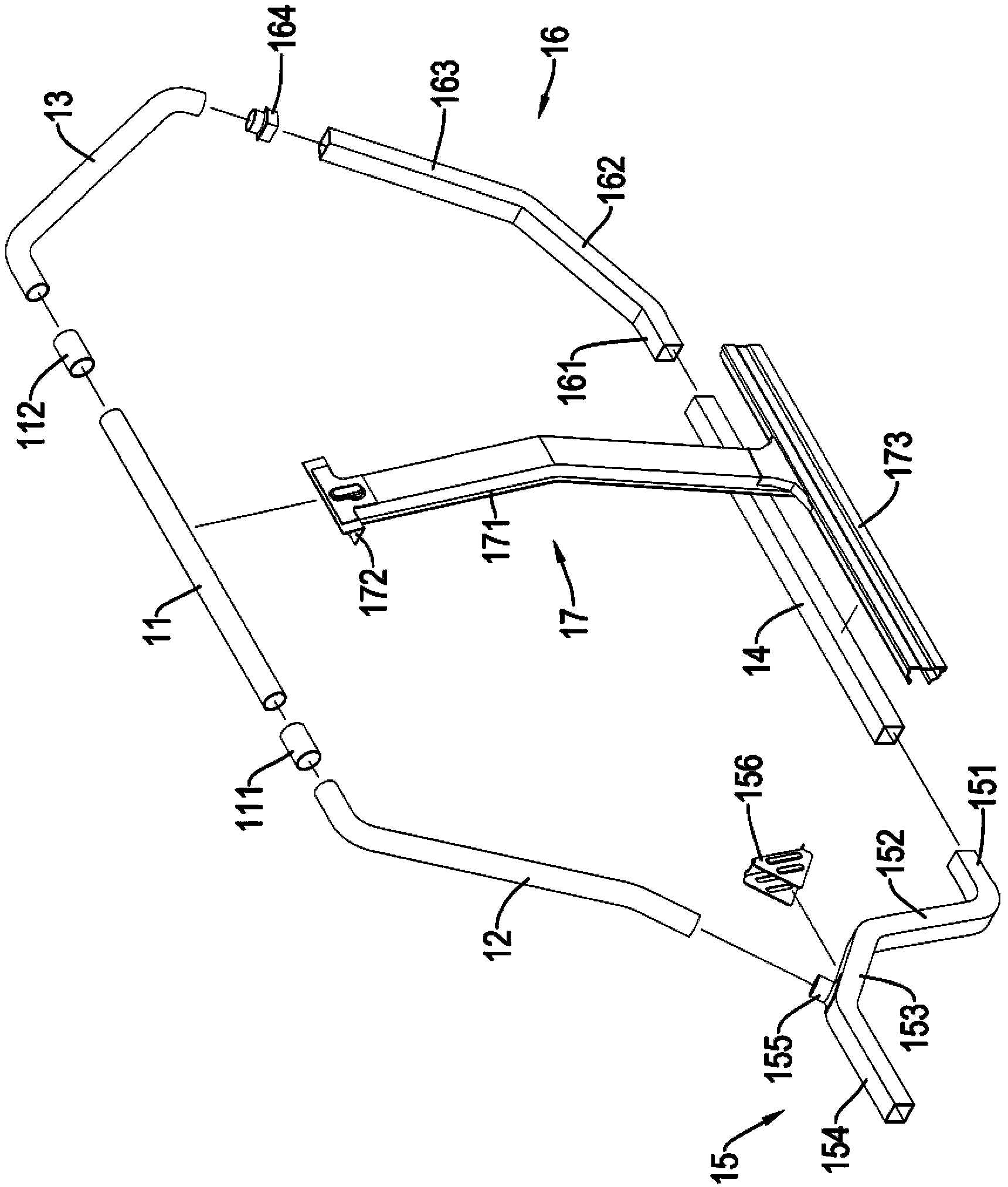

[0053] The vehicle body frames 10 on both sides are arranged on the left and right sides of the side girder frame vehicle body in a left-right symmetrical manner. Jacking pipe 11 is the elongated circular pipe body that extends along front and back direction, and a front sleeve pipe 111 is welded in the front end of each jacking pipe 11, and each front sleeve pipe 111 is circular pipe body and the rear half section is sleeved and welded on Around the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com