Single-boom gantry crane amplitude-variable compensation system and single-boom gantry crane

A compensation system and crane technology, applied in cranes and other directions, can solve problems such as increased hook weight, numerous compensation pulley blocks, and complicated wire rope winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

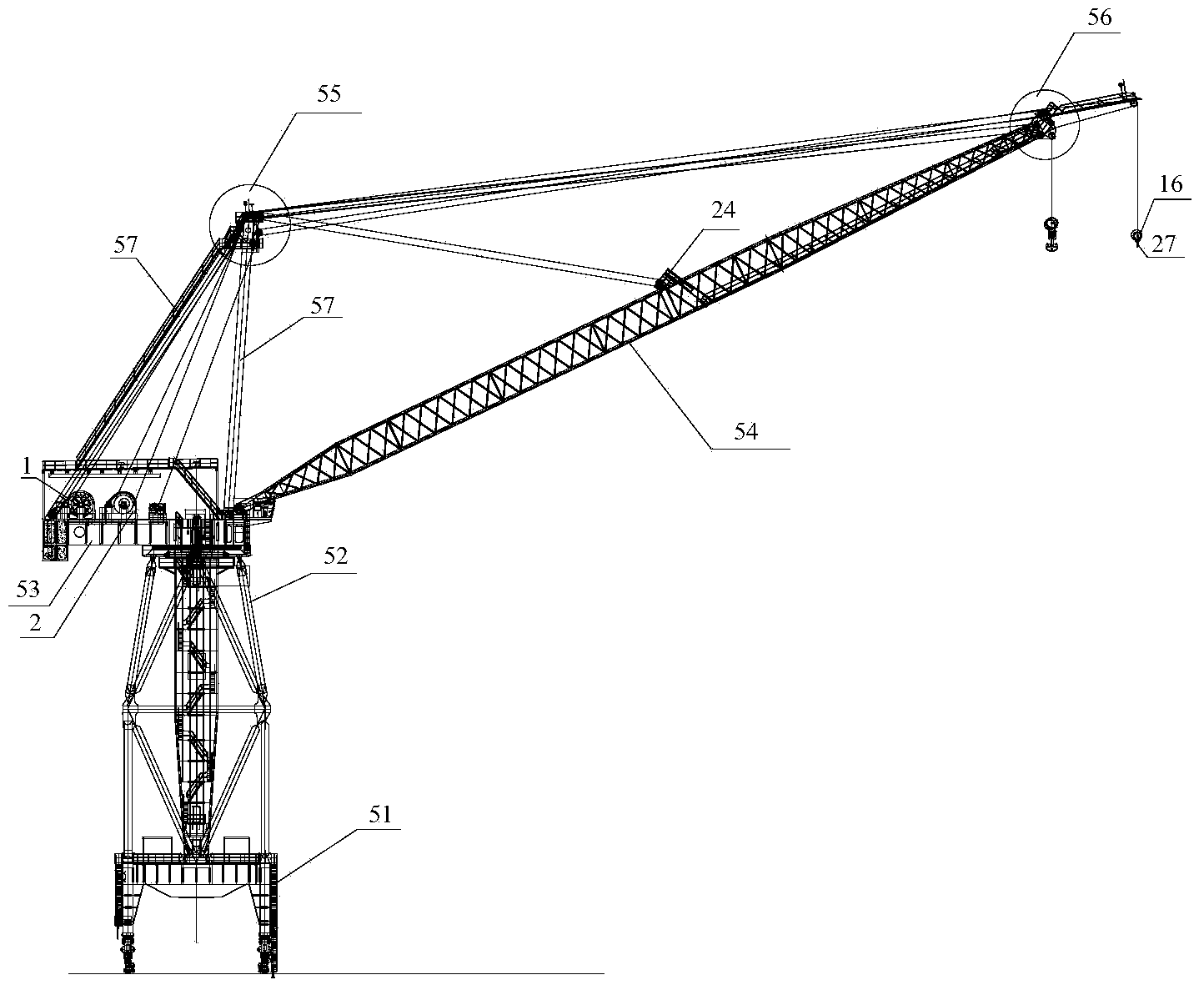

[0022] figure 2 Shown is a schematic diagram of the single-arm portal crane of the present invention, the single-arm portal crane includes a frame and a luffing compensation system, and the frame of the single-arm portal crane includes: a base 51, a portal frame 52, a turntable 53, Herringbone frame 57 and jib frame 54. The door frame 52 is fixed to the base 51 , the turntable 53 is arranged on the door frame 52 , and the herringbone frame 57 and the arm frame 54 are respectively arranged on the turntable 53 .

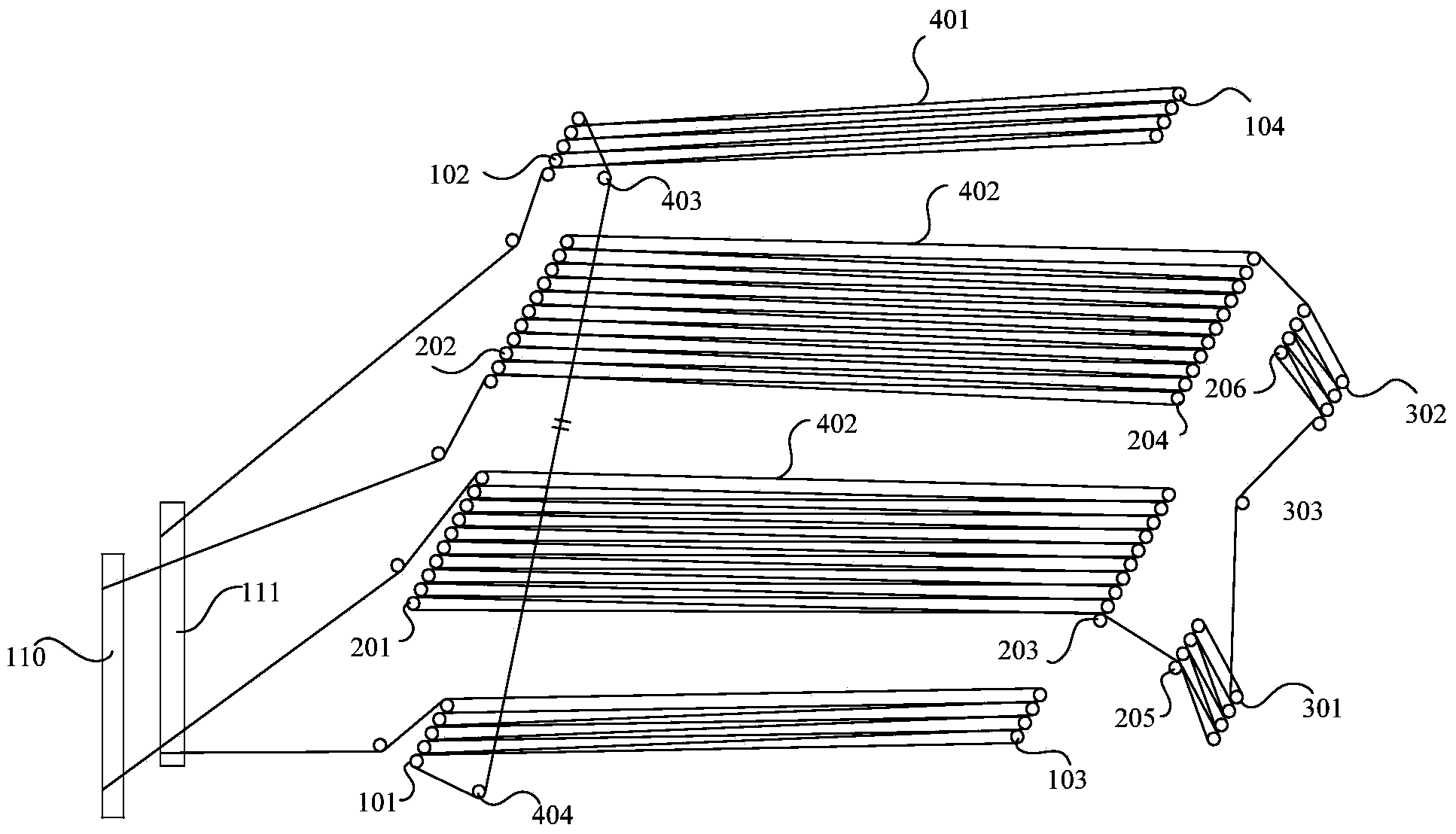

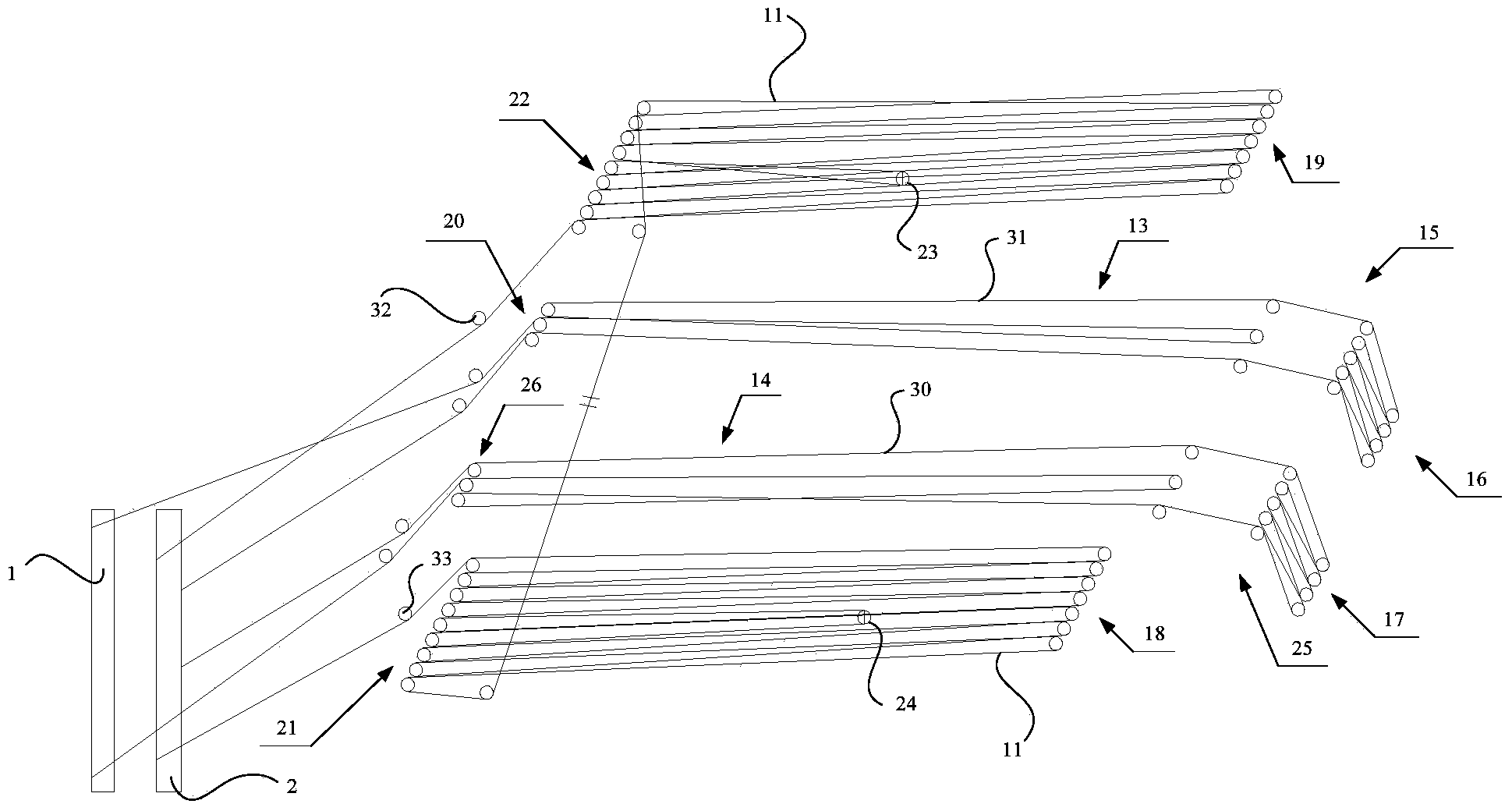

[0023] image 3 Shown is the schematic diagram of the luffing compensation system of the single-arm portal crane of the present invention, as figure 2 as well as image 3 As shown, the luffing compensation system includes lifting drum 1, luffing and compensation drum 2, two sets of compensation pulleys, two sets of luffing pulleys, two sets of hook pulleys, luffing wire rope 11, compensation wire rope 31, compensation wire rope 30. Multiple luffing guide pulleys ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com