A swing arm type pipe rod space slideway

A swing arm type and sliding way technology, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problems of increasing the safety factor, and achieve the effect of preventing collision, avoiding hidden dangers of wellhead operation, and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

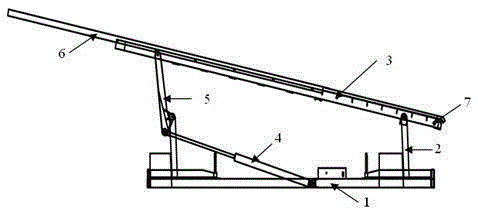

[0024] A swing arm type pipe rod space slideway is characterized in that it is composed of a mechanical part, a hydraulic system and an electrical system connected.

[0025] The mechanical part is composed of a base 1, a swing arm 2, a platform 3, a main hydraulic cylinder 4, a rotating arm 5, a slideway 6 and a flat delivery hydraulic cylinder 7, and the characteristics are: the base 1 is connected with the swing arm 2, the swing arm 2 One group is connected to the platform 3, and the other group is connected to the rotating arm 5. One end of the rotating arm 5 is connected to the main hydraulic cylinder 4, and the other end is inlaid to slide on the platform 3. The slideway 6 is installed on the platform 3, and the flat delivery hydraulic cylinder 7 is installed on the platform. 3, connected with slideway 6, can push slideway 6 to slide back and forth on platform 3.

[0026] The hydraulic system is composed of a hydraulic pump station, an operation control valve and a hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com