Check flushing valve capable of changing flushing directions automatically

An automatic conversion and non-return technology, applied in the direction of sliding valve, safety valve, balance valve, etc., can solve the problems of low efficiency and small scouring sediment range, so as to expand the scour range, reduce the resistance of pile pulling, and improve the efficiency of pile lifting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

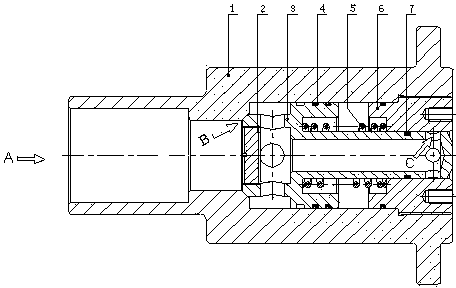

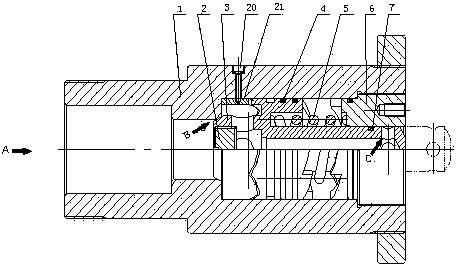

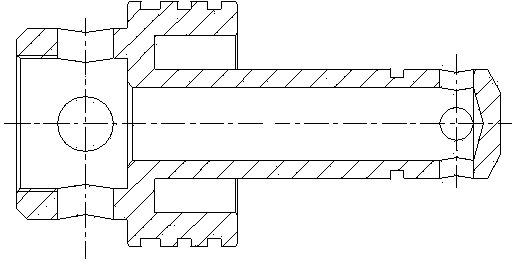

[0014] A non-return spray valve for automatic conversion of spray direction according to the present invention (see figure 2 ), there is a valve body 1 and a valve core 3, the valve cavity inside the inlet end of the valve body has a valve seat, the sealing end of the valve core in the valve cavity is correspondingly sealed with the valve seat, the other end of the valve core is a guide rod, and the guide rod is connected to the valve seat. The through hole of the end cover of the body is dynamically fitted, and the return spring 5 is arranged between the end cover 6 and the valve core 3. The side of the guide rod has a spray port C, and the spray port communicates with the valve cavity through the guide rod and the inner channel of the valve core. It is characterized in that there is a front positioning seat 21 around the valve seat in the valve cavity, a surrounding boss on the outer circle of the valve core, and end face teeth (also called special tooth type) with a 60° div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com