An oil breakdown controlled opening system for efd device and its manufacturing method

An oil breakdown and electrode technology, applied in the field of EFD display, can solve the problems of unpredictable oil layer movement, small hysteresis effect, and different oil layer breakdown points, etc., and achieve the effect of improving display effect, reducing hysteresis effect, and easy gray scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

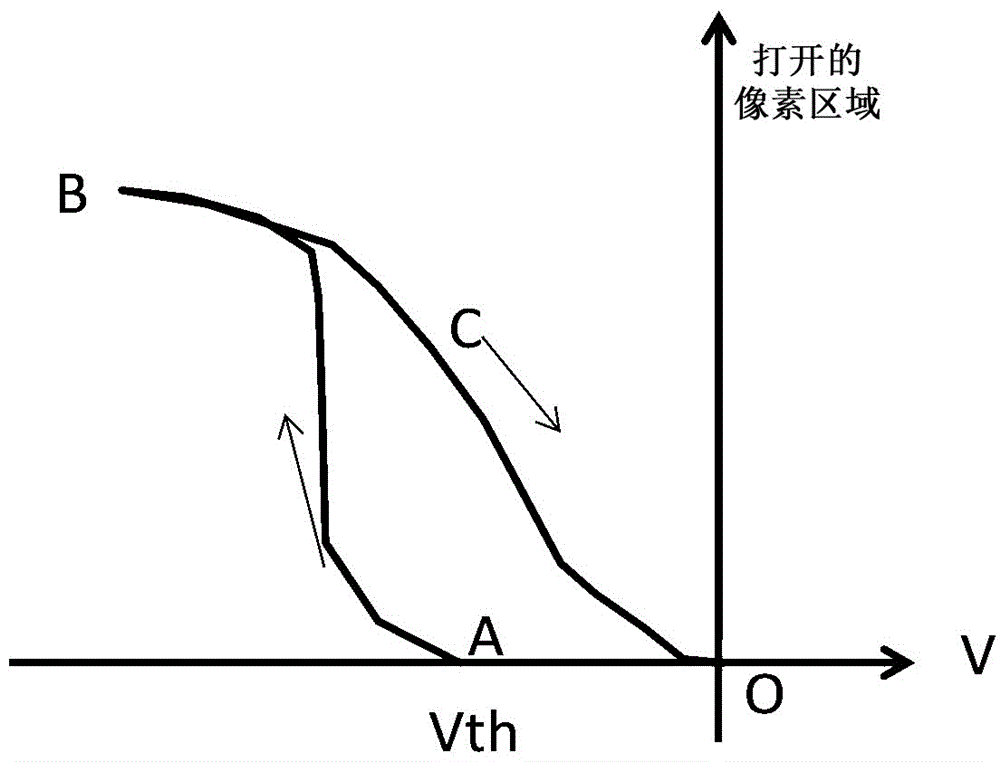

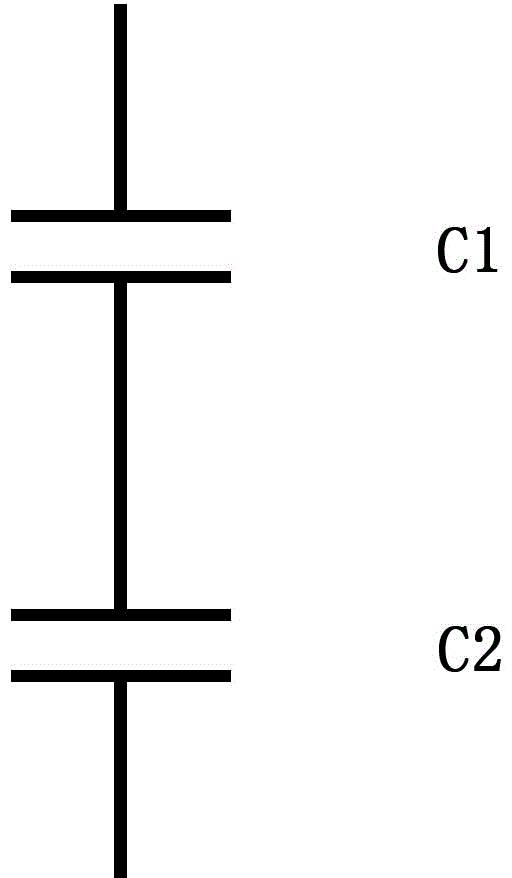

[0040] Such as image 3 As shown, in the existing EFD pixel design, the height of the pixel wall 3 is uniform, which makes the operation of the pixel more sensitive to the defects of the existing EFD display structure described in this paper, such as the inconsistent direction of oil layer movement and hysteresis effect . From an electrical point of view, an EFD pixel can be seen as a combination of two capacitances: C1 is the first liquid (e.g. oil layer) capacitance representing the inert liquid, and C2 is the dielectric layer capacitance representing the dielectric layer. Therefore, the total capacitance C=C1*C2 / (C1+C2). The charge accumulated on the interface is proportional to the total capacitance. In the following embodiments according to the present invention, this principle will be used to manufacture a novel pixel wall 3 structure and solve the above-mentioned problems.

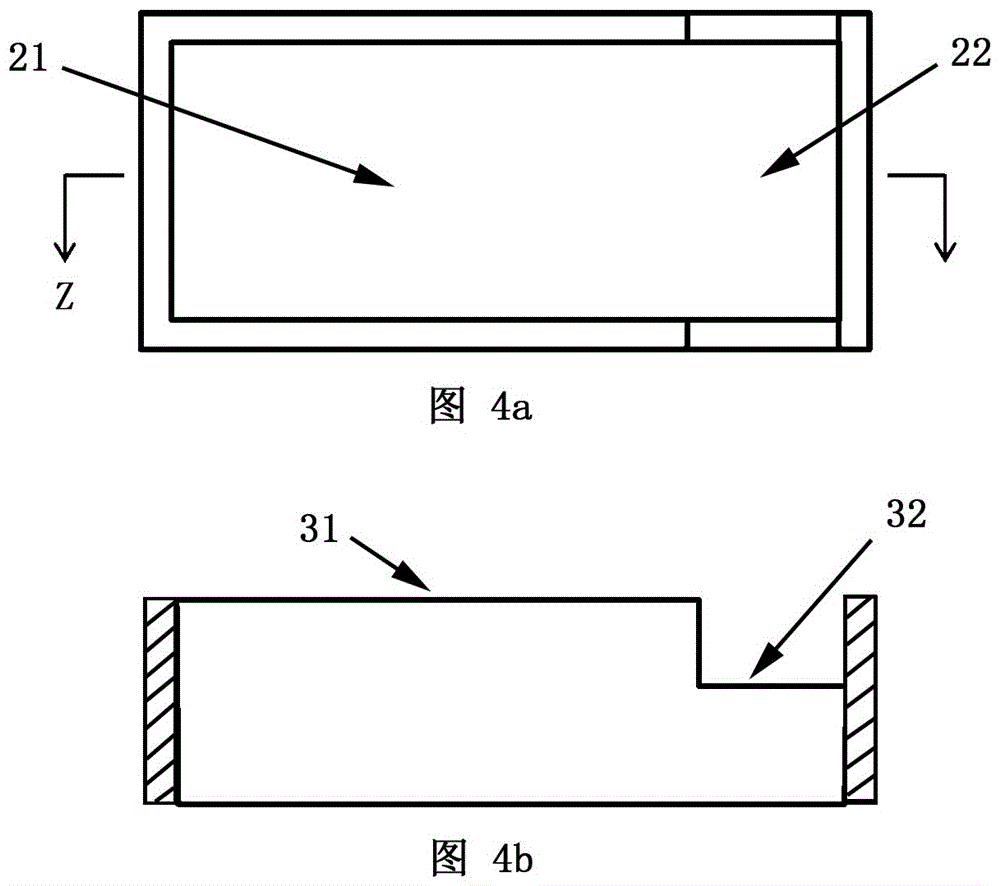

[0041] Such as Figure 4a and Figure 4b Shown is an EFD display structure with pixel walls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com