Printing machine remote fault monitoring system and method

A printing machine and fault detection technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems that the printing machine system has not been widely used and the degree of network is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

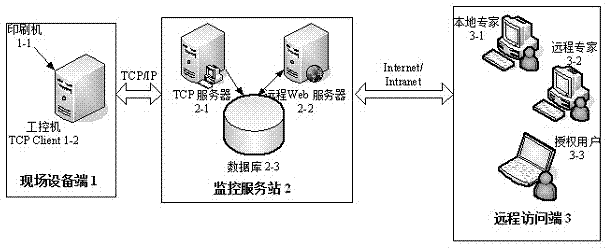

[0027] participate figure 1 , The remote fault diagnosis and monitoring system of this printing press includes a field device terminal 1, a monitoring service station 2 and a remote access terminal 3. The field device 1 communicates with the monitoring service station 2 via Ethernet, and the monitoring service station 2 communicates with the remote via the Internet or Intranet. Access terminal 3 communicates. Field device terminal 1 includes printing machine 1-1 and industrial computer 1-2. Monitoring service station 2 includes TCP server 2-1, remote Web server 2-2 and database 2-3. Remote access terminal 3 includes Authorized users 3-3, local experts 3-1 and remote experts 3-2 browsers, among them, the industrial computer on the field device side 1 collects real-time data from the printer on the field device side 1 through Ethernet, and the industrial computer 1-2 acts as The TCP client sends real-time data to the TCP server 2-1 of the remote monitoring service station 2, and t...

Embodiment 2

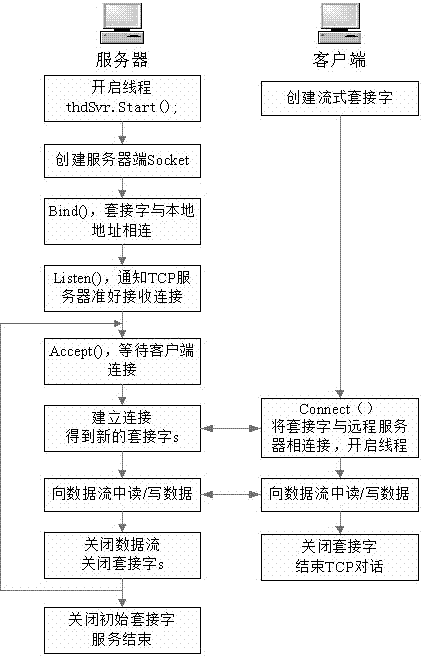

[0034] The remote fault detection method of the printing press adopts the above-mentioned system for remote diagnosis, including the following steps:

[0035] Step 1: The industrial computer 1-2 collects real-time data from the printing machine 1-1 and performs configuration;

[0036] Step 2: The industrial computer 1-2 serves as a TCP client to send the real-time data to the TCP server 2-1 of the remote monitoring service station 2;

[0037] Step 3: The database 2-3 classifies and stores the real-time data, manages users, monitors equipment, and performs remote fault diagnosis on equipment;

[0038] Step 4: The remote access terminal 3 accesses the remote Web server 2-2 through the Internet / Intranet to perform remote login, browse and query operations.

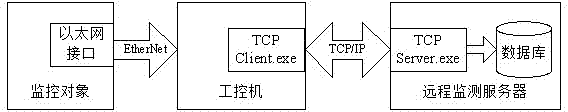

[0039] Such as figure 2 Shown is the block diagram of the basic process design for real-time data transmission on site. The industrial computer communicates with the equipment through Ethernet at the production site, can receive the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com