Industrial production line embedded type main control system

A main control system and embedded technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of failing to meet industrial-grade requirements, inability to control, and inability to adapt to high-speed data acquisition and control in industrial sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

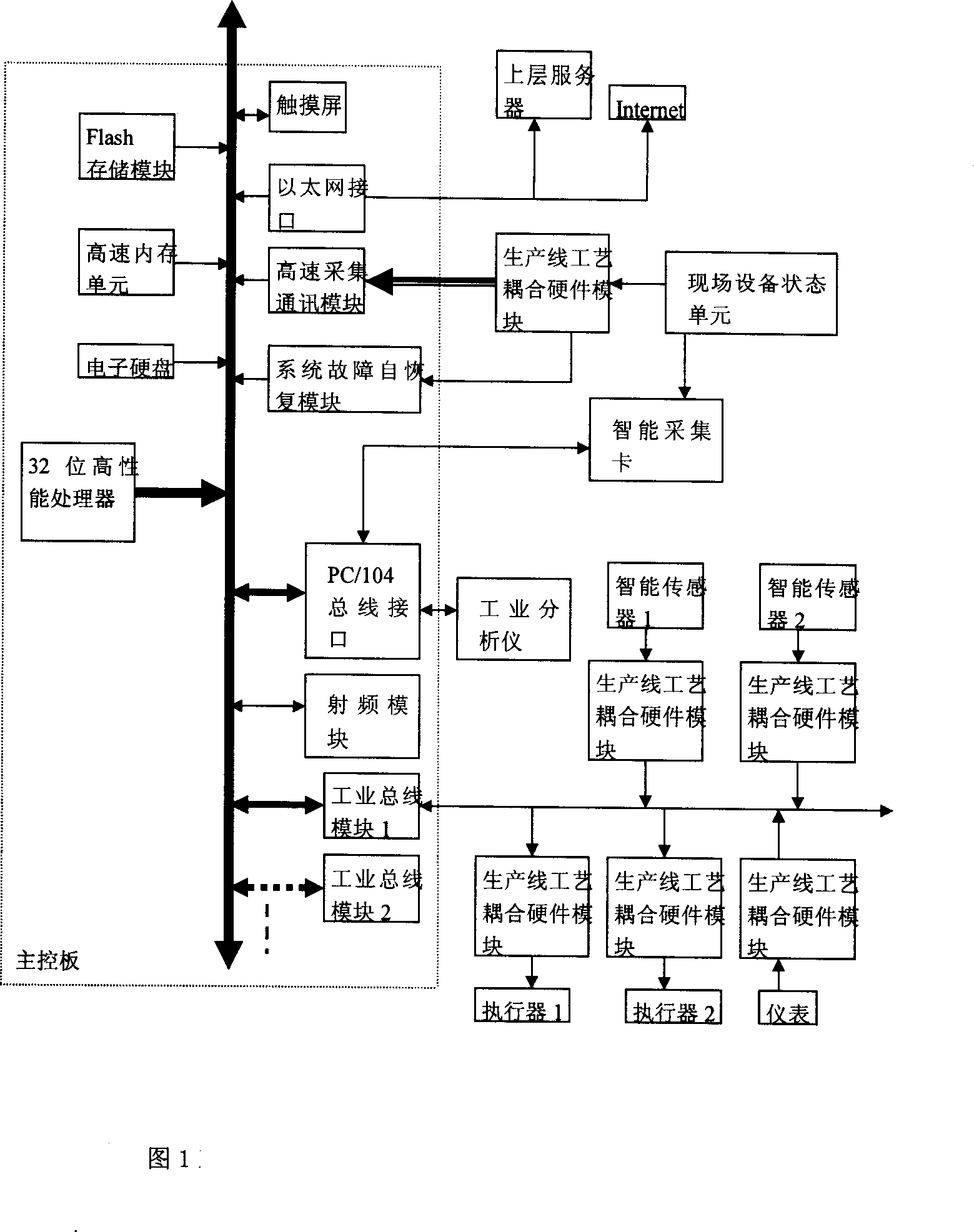

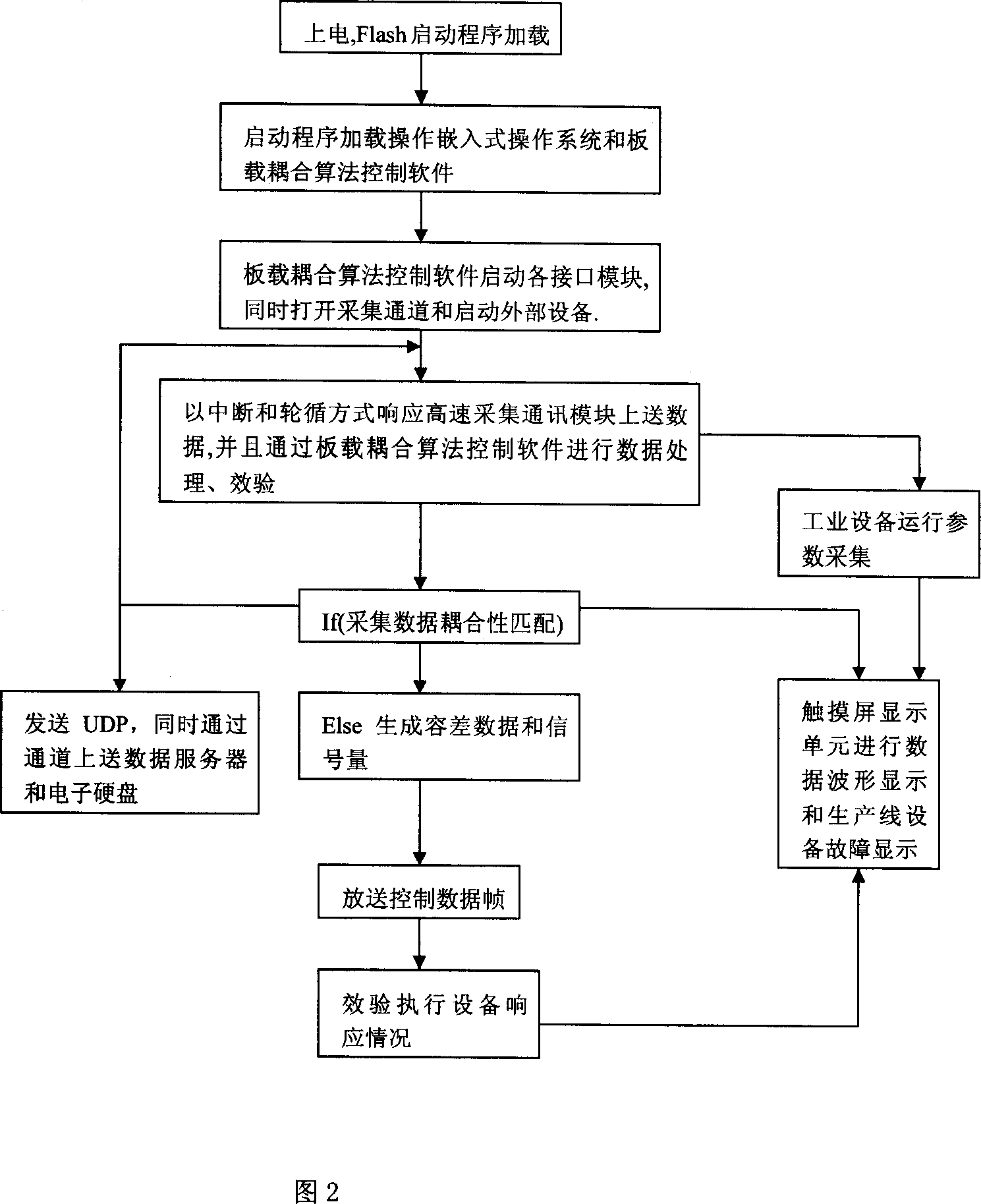

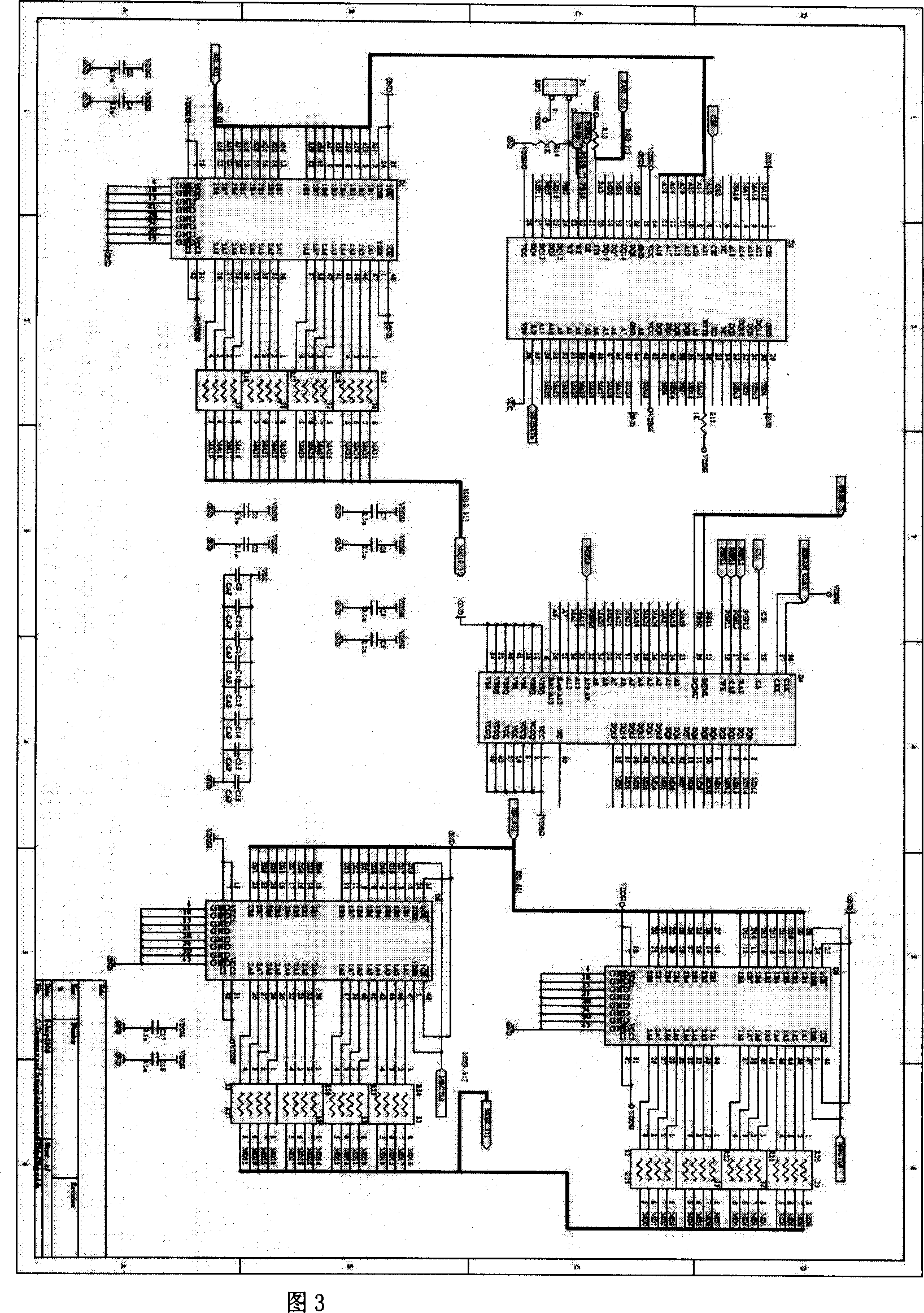

[0023] As shown in Figure 1, the high-performance data server is a central control system that has a professional application expansion bus and interface, and integrates a general interface platform. The system uses a high-performance 32-bit embedded processor and an embedded real-time operating system with multi-process parallel processing as the core central processing unit. The main control board integrates non-volatile Flash memory and high-speed memory unit, as shown in Figure 3, the small-capacity Flash memory stores the startup configuration information of the system, the large-capacity Flash memory stores the real-time operating system associated with the system, and integrates the coupling algorithm under the operating system The control system software implements each on-board module, realizes the optimized process management and control under the real-time operating system, and through the multi-layer fuzzy structure algorithm inside the software, realizes the comprehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com