A chip type protection element and its mass production method

A protection component and chip-type technology, which is applied in fuse manufacturing, electrical components, emergency protection devices, etc., can solve the problems of easy deposition of insulating shells by metal vapor, complex structural design of fuses, and difficulty in mass production, and achieve high reliability. The effect of performance and fusing consistency, improving high-voltage breaking capacity, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

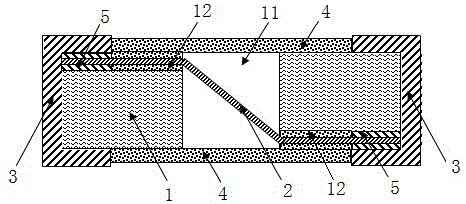

[0041] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a surface-mounted chip-type protection element, including an insulating substrate 1, a metal melt 2 disposed in the insulating substrate 1, end electrodes 3 formed at both ends of the insulating substrate 1 and formed on the insulating substrate 1. The protective layer 4 on the outer surface of the substrate 1, the metal melt 2 is electrically connected to the end electrodes 3 at both ends of the insulating substrate 1; a through hole 11 is formed in the middle of the insulating substrate 1, and the opening direction of the through hole 11 is in line with the end portion The electrodes 3 are vertical (that is, the connection line formed between the end electrodes is perpendicular to the axial direction of the through hole 11), and the upper and lower surfaces of the insulating substrate 1 (where upper and lower refer to figure 1 The direction in the middle) are respectively provided with ...

Embodiment 2

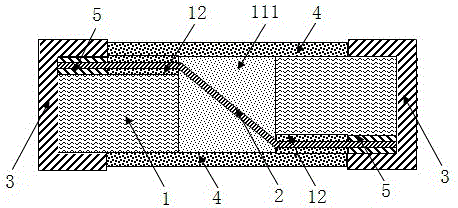

[0065] As an improvement of Embodiment 1, such as figure 2 As shown, the through hole 11 is filled with an arc extinguishing material 111, which can extinguish the arc generated when the metal melt is broken, and improves the arc extinguishing capability of the product. The remaining structural features in this example are the same as those in Embodiment 1.

[0066] When mass-manufacturing the chip-type protective components provided in this example, the following steps are added between the mass-manufacturing step (3) conductive adhesive printing and step (4) protective layer addition in Example 1: arc-extinguishing material injection step:

[0067] The arc extinguishing material 111 is injected into the through hole 11 by using a dispensing machine dispensing process (other conventional processes can also be used), and the arc extinguishing material 111 can extinguish the arc generated at the moment when the metal melt 2 is disconnected , Adsorb metal vapor, reduce the pr...

Embodiment 3

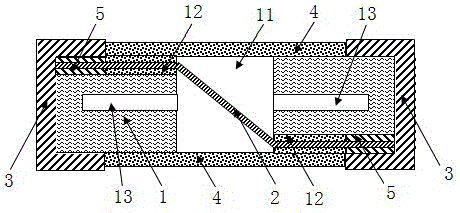

[0070] As an improvement of embodiment one or embodiment two, such as image 3 As shown, at least one decompression groove 13 is formed inside the insulating substrate 1, and the decompression groove 13 communicates with the through hole 11, so that the impact of the metal vapor pressure generated during breaking on the protective layer 4 can be reduced, and the durability of the product is improved. breaking capacity. The decompression groove 13 is preferably perpendicular to the direction of the through hole, and has a strong decompression capability. The rest of the structural features of the fuse in this example are the same as in the first embodiment or the same as in the second embodiment. The arc extinguishing material 111 can extinguish the arc generated when the metal melt is broken, and the decompression groove 13 can effectively reduce the pressure impact of the metal vapor, thereby obtaining a chip-type protective element with higher breaking capacity.

[0071] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com