Detachable large-current connector

A high-current connector, high-current technology, applied in the direction of connection and connection device components, circuits, etc., can solve the problems of connector scrap, disassembly difficulty, and high manufacturing cost, and achieve convenient maintenance and installation, and anti-vibration effects. Good, low-cost manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

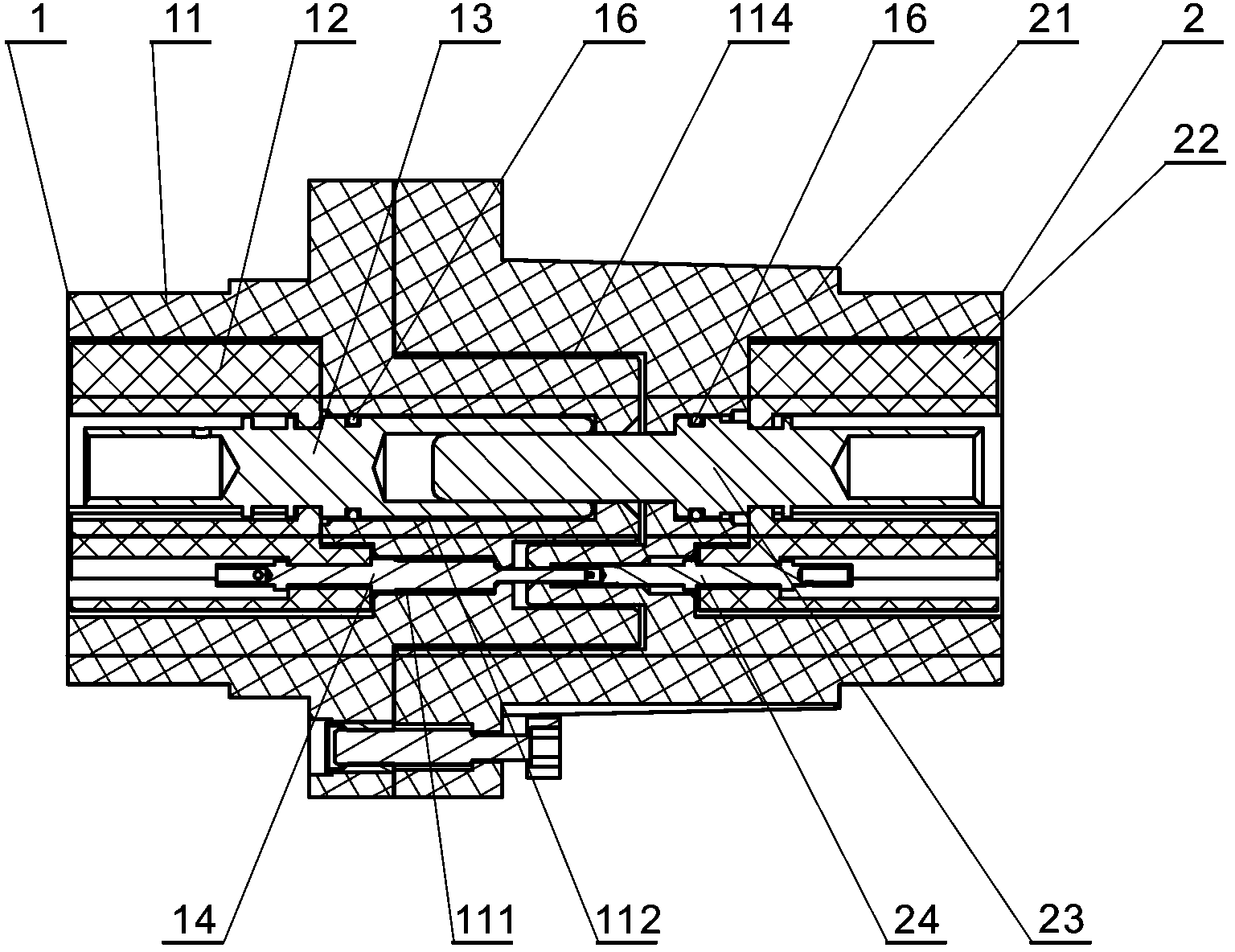

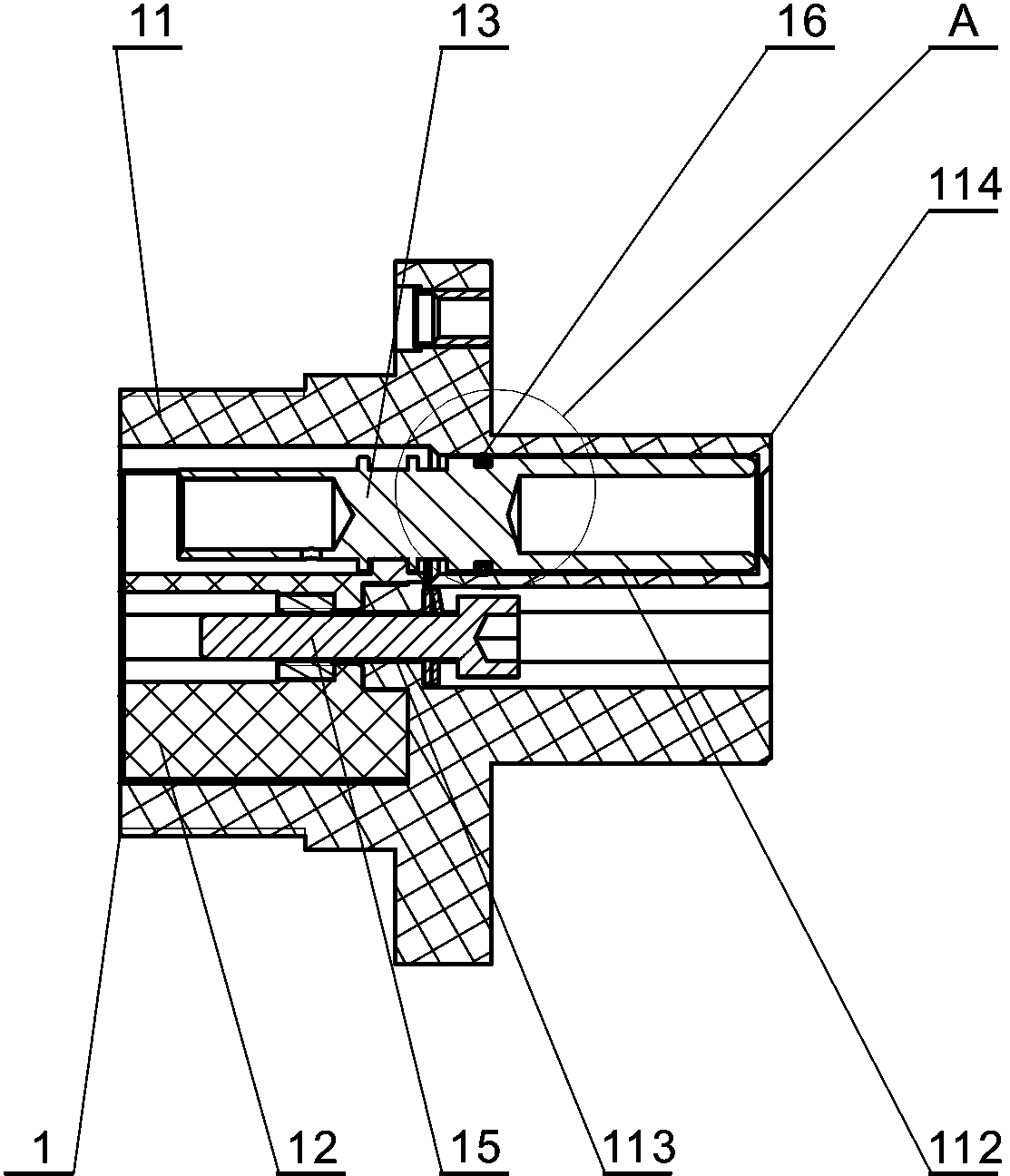

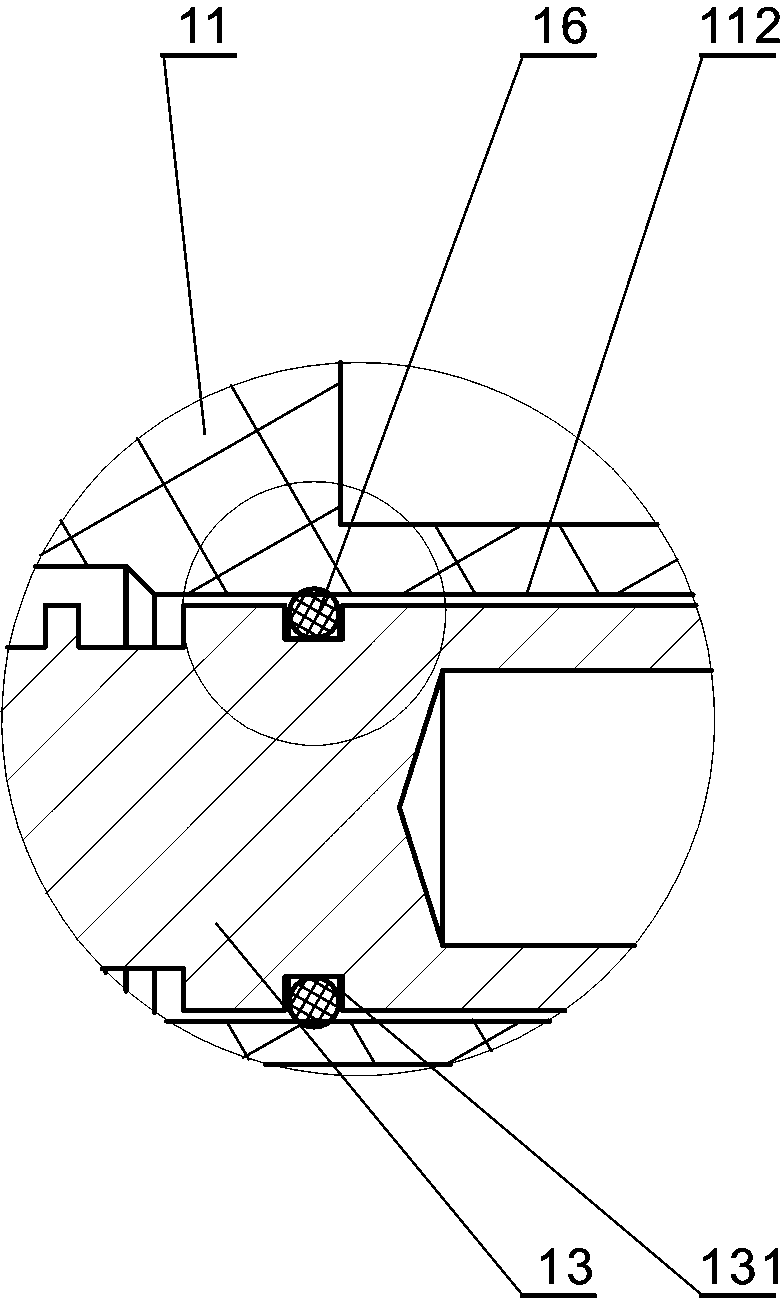

[0021] refer to Figure 1 to Figure 7 , the present invention includes a socket 1 and a plug 2, the socket 1 is composed of a seat insulator 11, a seat cover 12, a large current jack 13, a small current pin 14, a screw 15 and a sealing ring 16, wherein the seat insulator 11 is One end is provided with a raised flat square 114, and the other end is provided with a cylindrical body with a recessed seat hole. It is provided with two small sockets 111, three large sockets 112 and a screw hole 113 in the axial direction. The seat cover plate 12 It is a columnar body, on which two small gaps and three large gaps 121 corresponding to the small socket 111 and the large socket 112 of the seat insulator 11 are arranged in the axial direction, and a large gap 121 in the center is provided with a wide protrusion. The platform 123 and the remaining two large gaps 121 are provided with a narrow boss 124, and a through hole 122 corresponding to the screw hole 113 is also provided on it.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com