Safety socket

A technology of safety socket and socket core, which is applied in the direction of the base/housing, electrical components, coupling devices, etc., can solve the problems of inconvenient operation, complex structure, poor safety, etc., and achieve the prevention of leakage and short circuit accidents, convenient operation and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

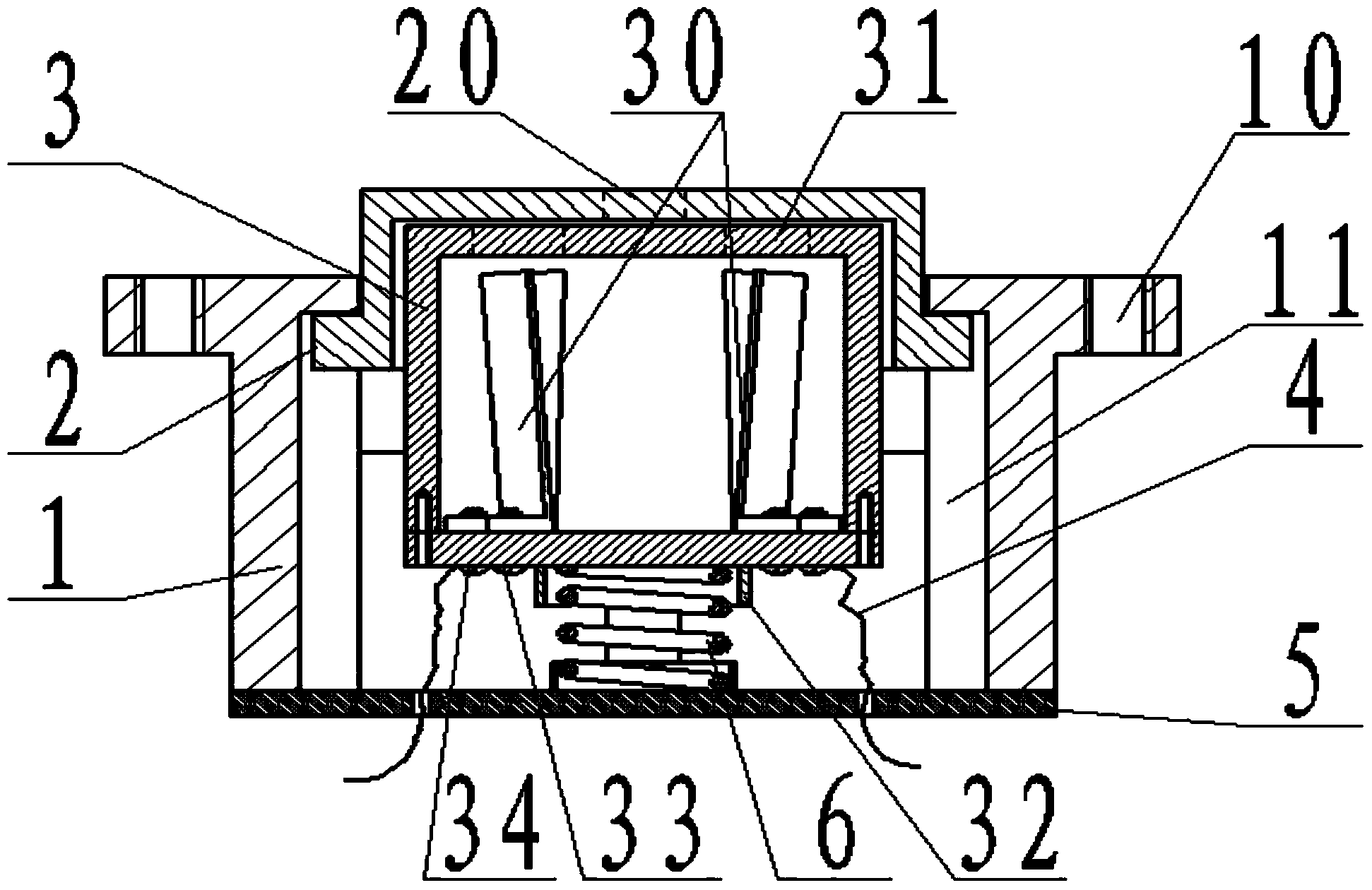

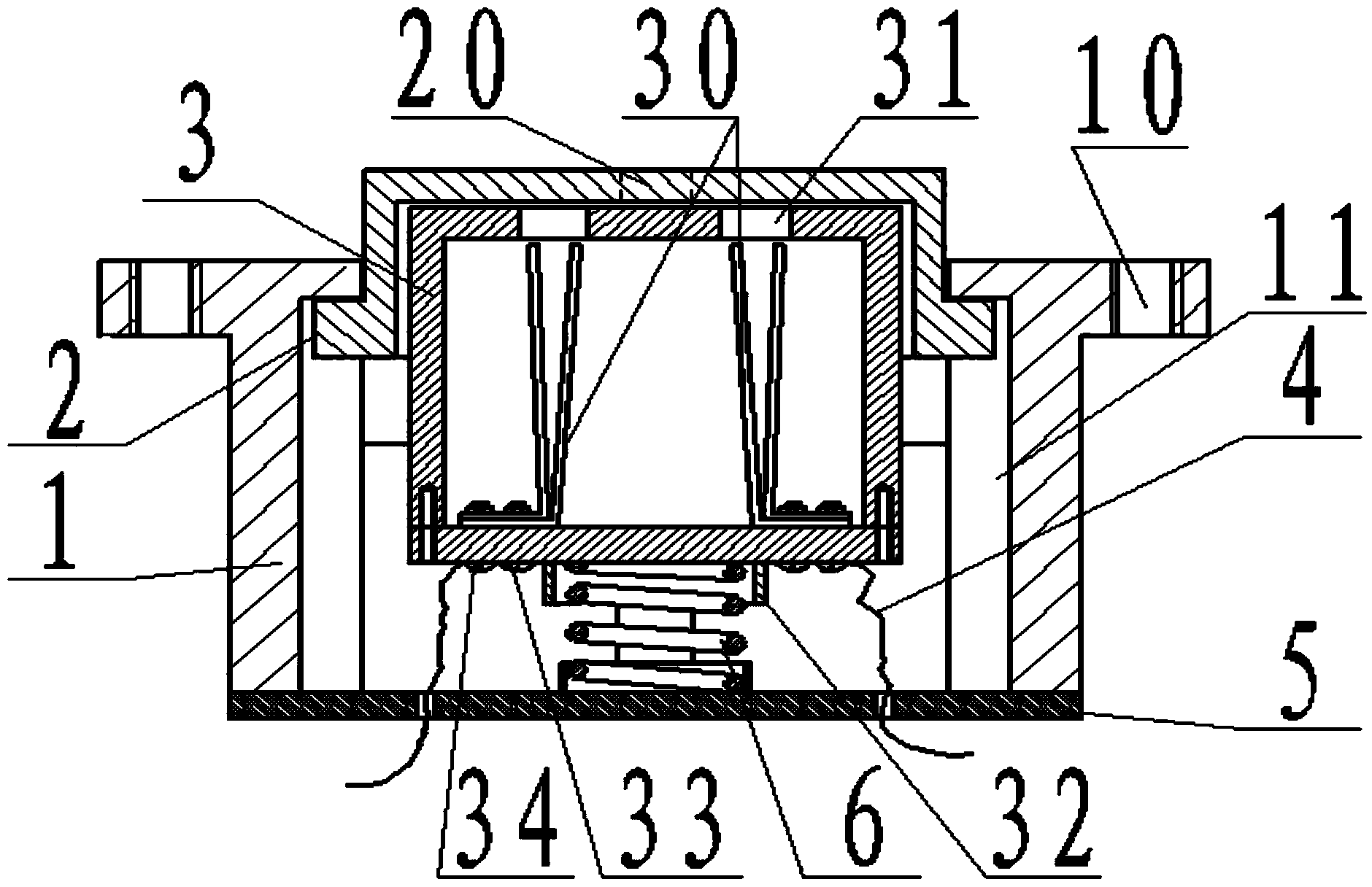

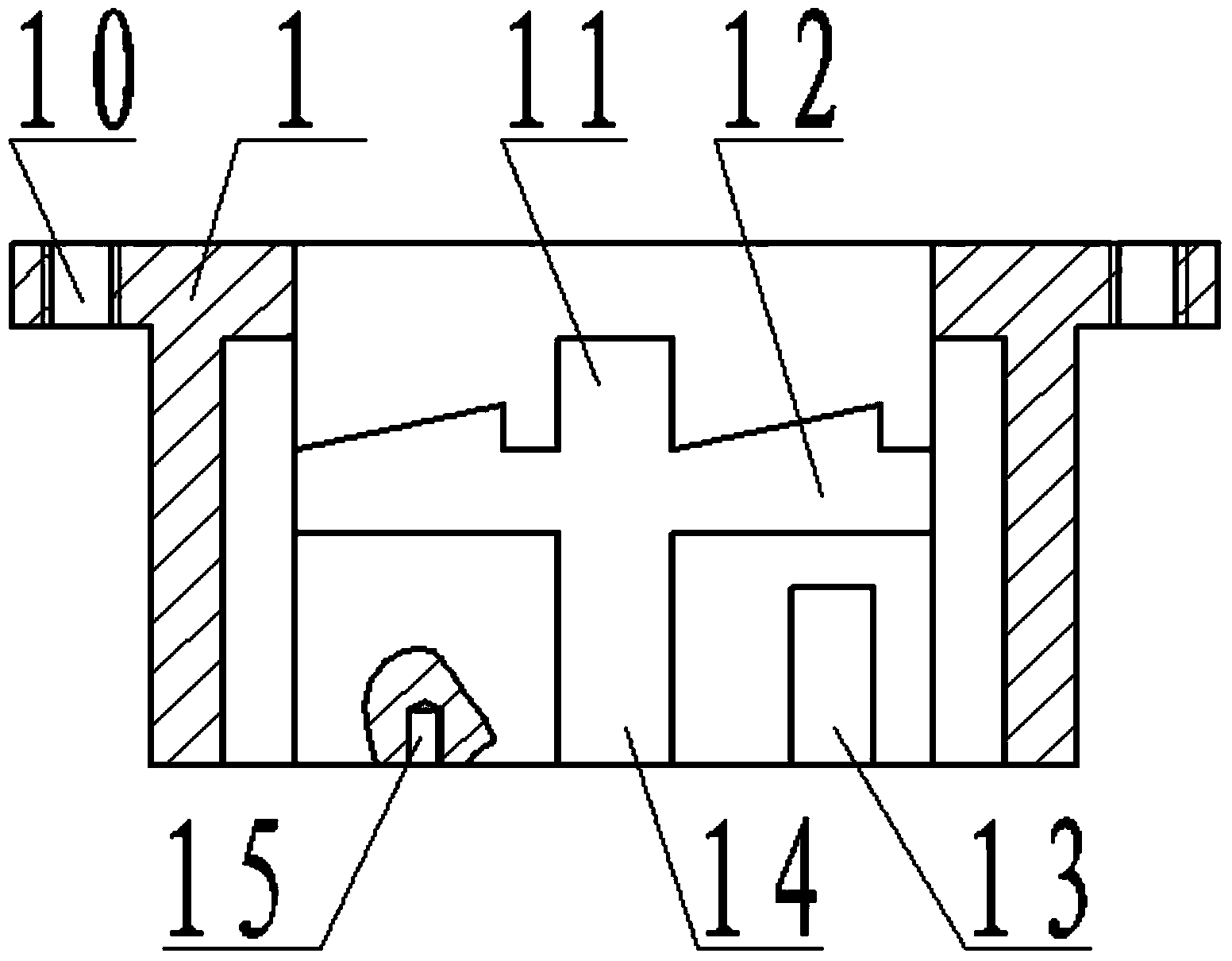

[0030] Such as figure 1 , 3 , 4, 6, a safety socket, including a socket cover, a socket hole, a base, and a power supply foot 30, wherein: the base is a socket core sleeve 1, and the socket core sleeve 1 is provided with a baffle 5, the baffle 5 is provided with a limit groove for the spring 6, a fixing hole and a power cord hole, the power cord hole corresponds to the power supply foot 30, and the baffle plate 5 is fixed on the socket core sleeve 1 with screws through the fixing hole and the screw hole II15. The socket cover is a swivel cover 2, and the swivel cover 2 is provided with socket I20 and swivel cover bumps 21, the number of swivel cover bumps 21 is corresponding to the safety groove 11 and the installation groove 14, and is evenly distributed on the outer surface of the swivel cover 2, and the swivel cover 2 There is a knurling on the part protruding from the socket core sleeve 1 surface. The socket core sleeve 1 is provided with a socket core 3, and the upper e...

Embodiment 2

[0032] Such as figure 2 , 3, 5, and 7, a safety socket, including a socket cover, a socket hole, a base, and a power supply foot 30, wherein: the base is a socket core cover 1, and the socket core cover 1 is provided with a baffle 5, and the baffle 5 is provided with a limit groove for the spring 6, a fixing hole and a power cord hole, the power cord hole corresponds to the power supply foot 30, and the baffle plate 5 is fixed on the socket core sleeve 1 with screws through the fixing hole and the screw hole II15. The socket cover is a swivel cover 2, and the swivel cover 2 is provided with socket I20 and swivel cover bumps 21, the number of swivel cover bumps 21 is corresponding to the safety groove 11 and the installation groove 14, and is evenly distributed on the outer surface of the swivel cover 2, and the swivel cover 2 There is a knurling on the part protruding from the socket core sleeve 1 surface. The socket core sleeve 1 is provided with a socket core 3, and the u...

Embodiment 3

[0034] refer to figure 1 , 3 , 4, 6, a kind of safety socket, comprises socket cover, socket hole, base, power base 30, wherein: described base is socket core cover 1, and socket core cover 1 is provided with baffle plate 5, and baffle plate 5 is provided with There are limit slots for the spring 6, fixing holes and power cord holes. The power cord holes correspond to the power supply feet 30, and the baffle plate 5 is fixed on the socket core sleeve 1 with screws through the fixing holes and the screw holes II15. The socket cover is a swivel cover 2, and the swivel cover 2 is provided with socket I20 and swivel cover bumps 21, the number of swivel cover bumps 21 is corresponding to the safety groove 11 and the installation groove 14, and is evenly distributed on the outer surface of the swivel cover 2, and the swivel cover 2 There is a knurling on the part protruding from the socket core sleeve 1 surface. The socket core sleeve 1 is provided with a socket core 3, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com