Carrier platform

A technology for supporting platforms and supporting structures, applied in power transmission AC networks, electrical components, substations, etc., can solve the problems of difficult assembly process, expensive materials, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

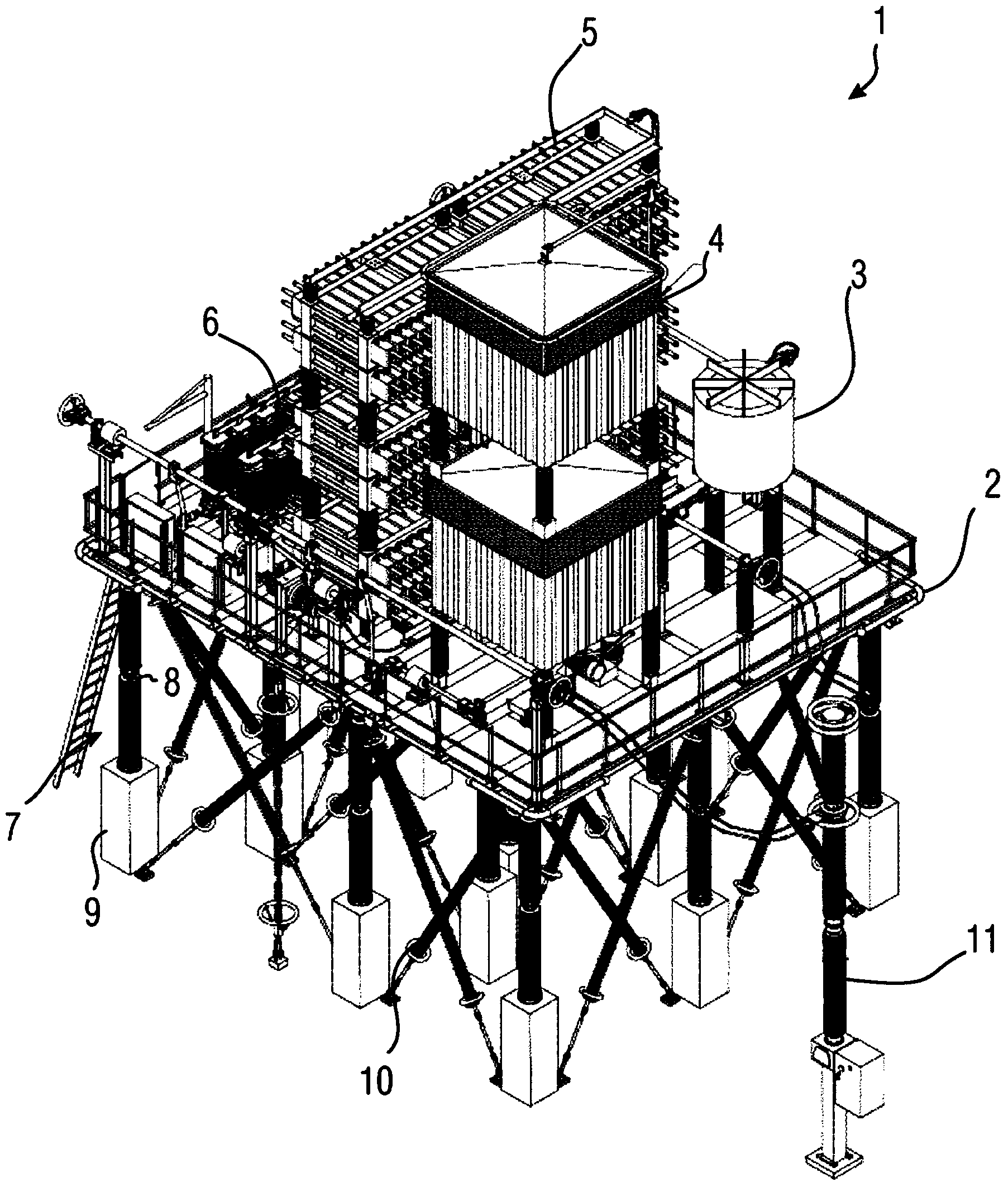

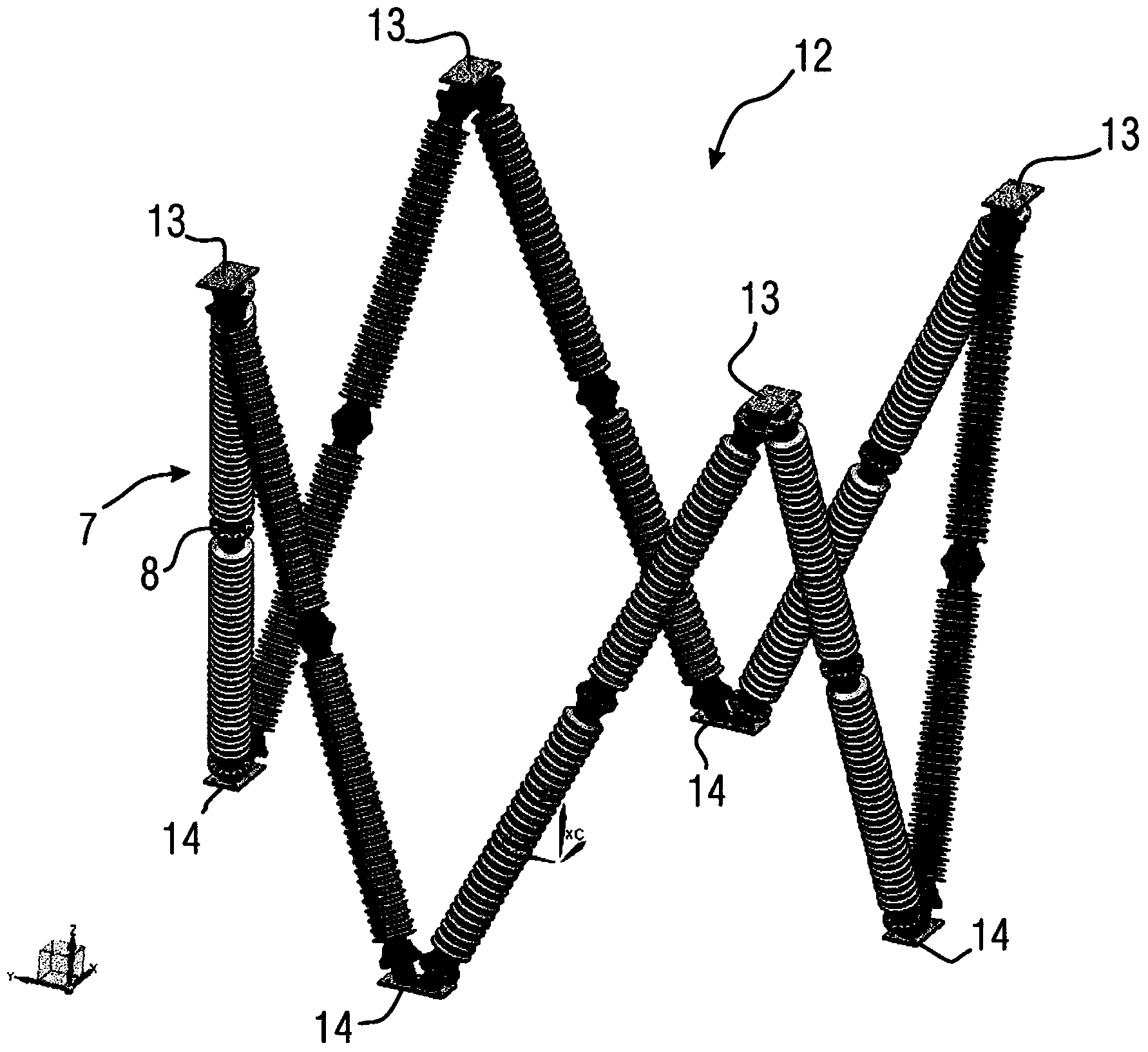

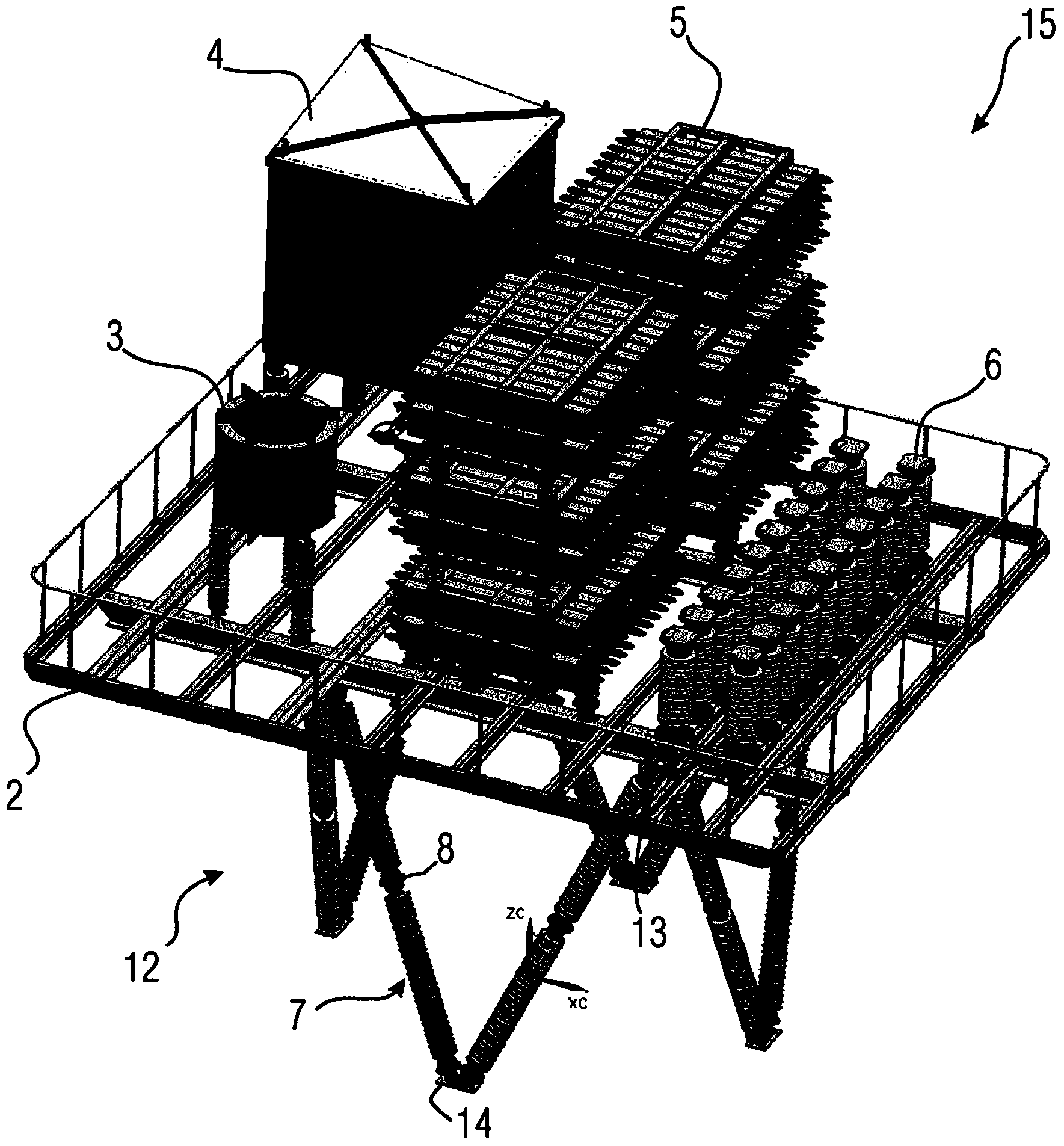

[0017] Figure 1 shows a device 1 according to the prior art. The device 1 has a support platform 2 which is oriented flat and horizontal. A high-voltage system in the form of a choke ring 3 , a spark discharge device 4 , a capacitor bank 5 and an electrical conductor 6 is arranged on the support platform 2 . In operation, said high voltage devices 3, 4, 5 and 6 are at a high potential, eg 200 kV. Furthermore, the device has a supporting insulator 7 which consists of two parts and has a connection joint 8 . Each support insulator 7 extends from the support platform 2 perpendicularly to the respective base 9 embedded in the ground. In order to be able to reliably absorb the load of the support platform 2 in the event of breakage of the support insulator 7 , the support insulator 7 arranged on the outside of the support platform 2 , that is to say in the edge region, and the other inner vertical support insulator 7 are provided. In addition, a tension-compression insulator 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com