Measuring device for electrically measuring a flat measurement structure that can be contacted on one side

A measurement device and electrical measurement technology, which is applied in the field of measurement structure, can solve the problems of measurement result distortion, time-consuming, distortion, etc., and achieve the effect of speeding up the connection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

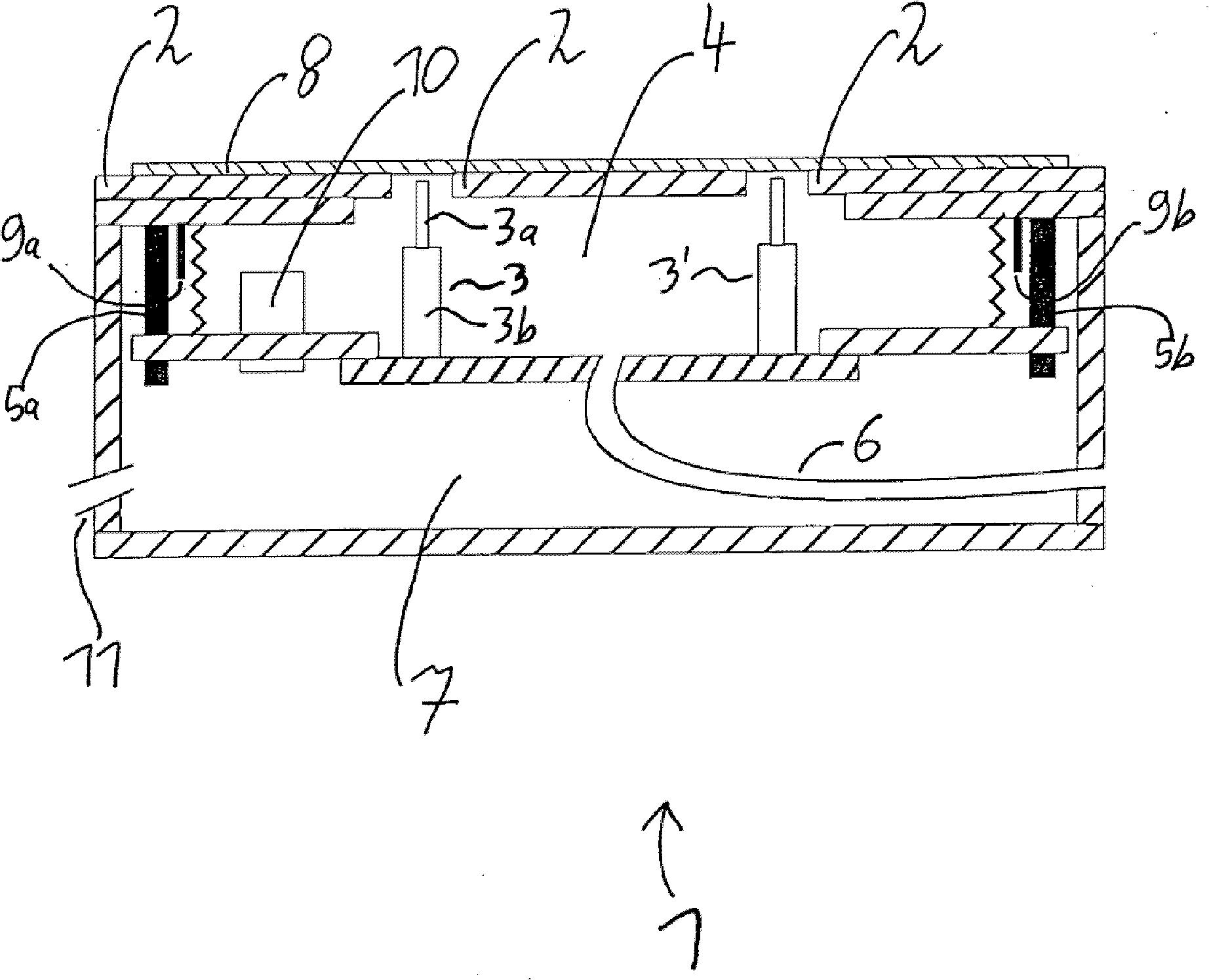

[0068] figure 1 A sectional view of an exemplary embodiment of the measuring device 1 according to the invention is shown, the sectional view extending perpendicularly to the carrier element 2 . The carrier element 2 is designed in one piece and has two recesses, figure 1 The sectional view shown in extends through the gap.

[0069] The measuring device has a plurality of switch-on units 3, in figure 1 Two of them (3, 3') are shown in the cross-section shown. The switch-on unit 3 is designed as a spring contact pin with pin 3a, figure 1 The pin in is supported in the cylindrical housing 3b so as to be movable upwards and downwards. The pin 3 a is spring-loaded, so that in the unloaded state the pin moves upwards.

[0070] The switch-on unit 3 is arranged on the bottom element of the first vacuum chamber 4 . The vacuum chamber is delimited upwards by the support element 2 and downwards by said bottom element. The vacuum chamber is sealed laterally by bellows-shaped eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com