Multi-functional, efficient and energy-saving rapid condensing tank

A high-efficiency, energy-saving and multi-functional technology, applied in the field of condensing tanks, can solve the problems of lagging cooler design technology, etc., and achieve the effects of multi-functional and wide-ranging convenience, compact and reliable structure, and superior design technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

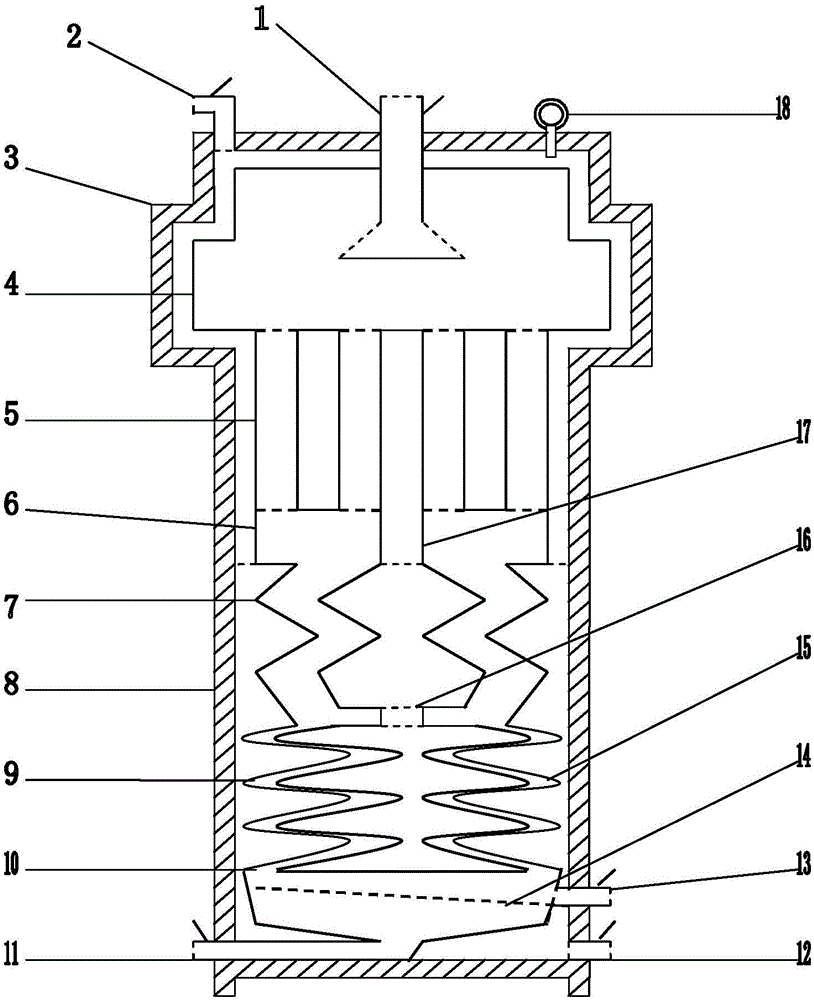

[0013] as attached figure 1 As shown, the multifunctional high-efficiency energy-saving quick-setting tank of the present invention includes two parts: a main body and an attached body:

[0014] The main body includes an outer convex tank 3, an inner convex tank 4, a straight cooling pipe 5, a cooling bag 6, a condensation tank 7, an outer straight tank 8, a left condensation pipe 9, a lower accumulation bag 10, an inclined filter screen 14, and a right condensation pipe 15. Intercooler 17,

[0015] The outer convex tank 3 is arranged on the outer side and the lower end of the inner convex tank 4 and connected to the upper end of the outer straight tank 8, and its main function is to form the outer body of the quick-setting tank with the outer straight tank 8,

[0016] The inner convex tank 4 is arranged on the inner side of the outer convex tank 3 and the lower end is connected with the upper end of the direct cooling pipe 5 and the upper end is connected with the outer side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com