Turning conveyor with jolt shaping function

A conveyor and functional technology, applied in the field of conveyors, can solve problems such as unsatisfactory auxiliary functions, and achieve the effect of increasing the scope of use, good general performance, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

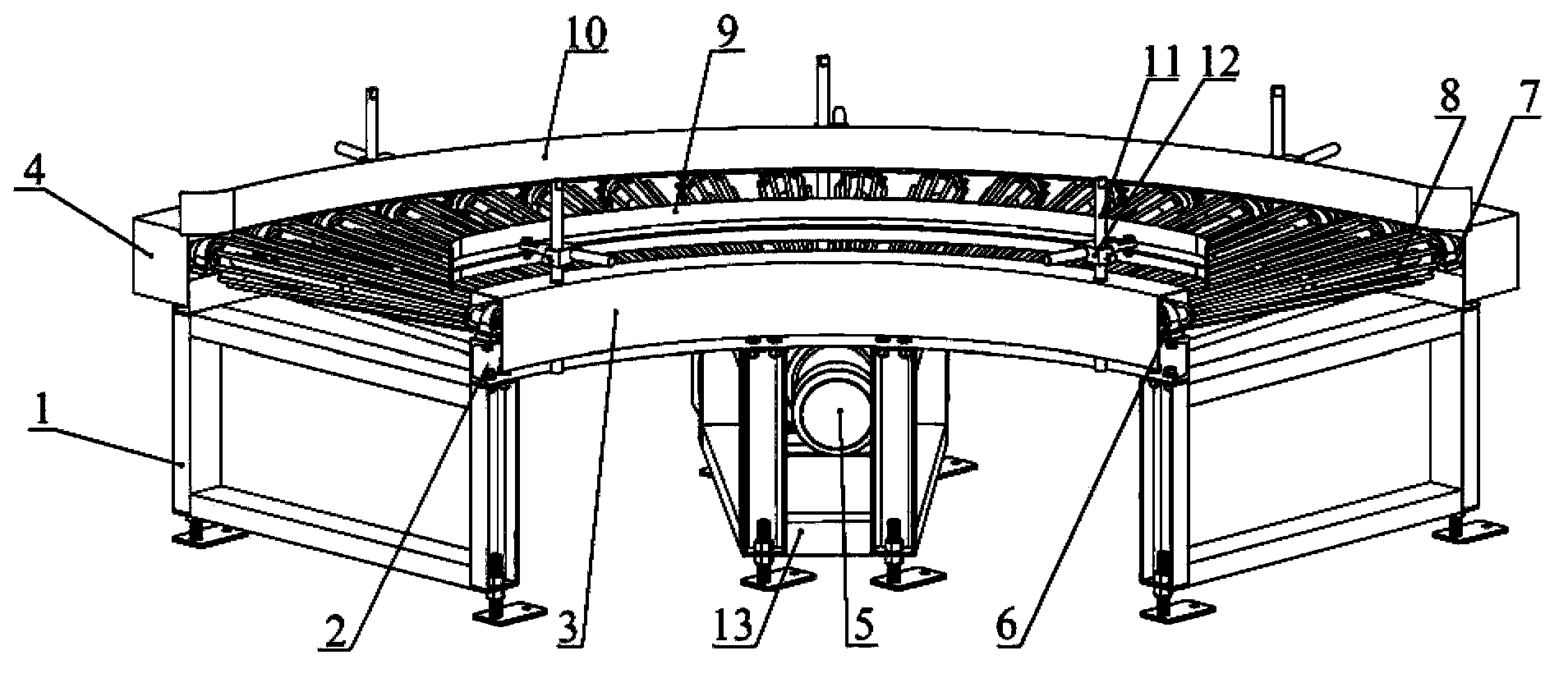

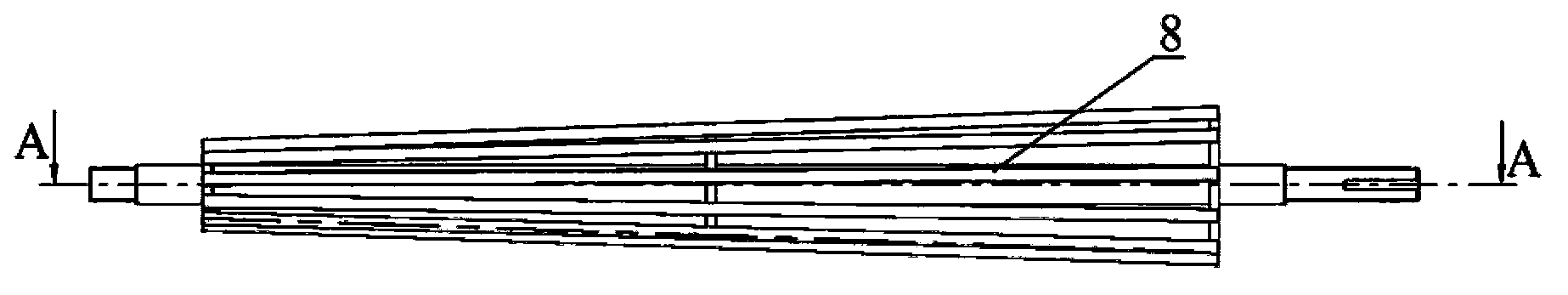

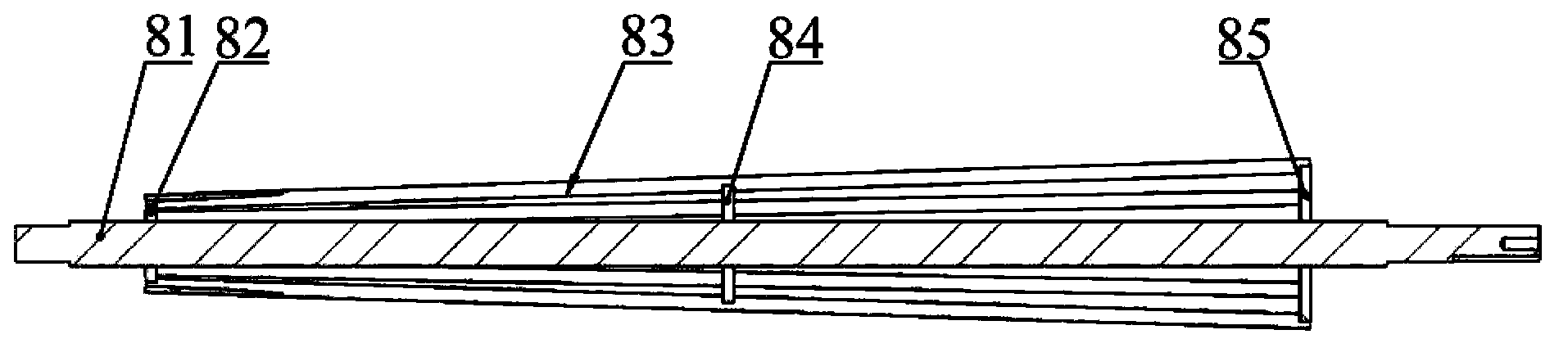

[0026] A curved conveyor with bump shaping function, such as figure 1 As shown, the conveyor includes a support device, a transmission device and a protective device. The support device includes a leg 1 and an arc-shaped skeleton 2 connected to the leg 1; the transmission device includes a power motor 5, a bearing with a seat 6, a tapered roller Assemblies 8 and transmission sprocket 7, power motor 5 are arranged under the frame 2, bearings with seats 6 are arranged at the front and rear ends of the frame 2, tapered roller assemblies 8 are evenly laid between the bearings with seats 6, adjacent tapered rollers The components 8 and between the tapered roller assembly 8 and the bearing with seat 6 are connected through the transmission sprocket 7, and the power motor 5 drives the tapered roller assembly 8 to rotate through the bearing with seat 6 and the transmission sprocket 7; The inner cover plate 3 and the outer cover plate 4 at the inner and outer ends of the roller assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com