Washing machine and washing machine driving method

A driving method and washing machine technology, applied in the field of washing machines, can solve the problems of increasing the weight of the whole machine, low reliability, unfavorable handling, etc., and achieve the effects of reducing the weight of the whole machine, ensuring stable operation, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not relevant to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

[0014] Washing machine example:

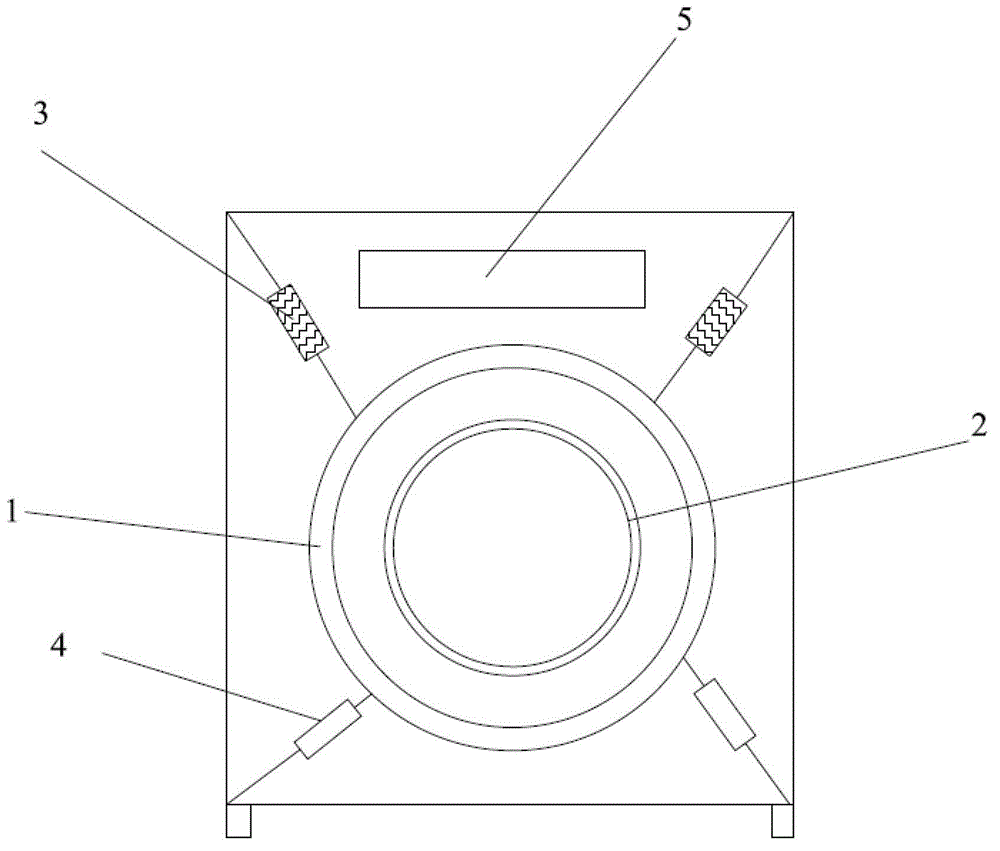

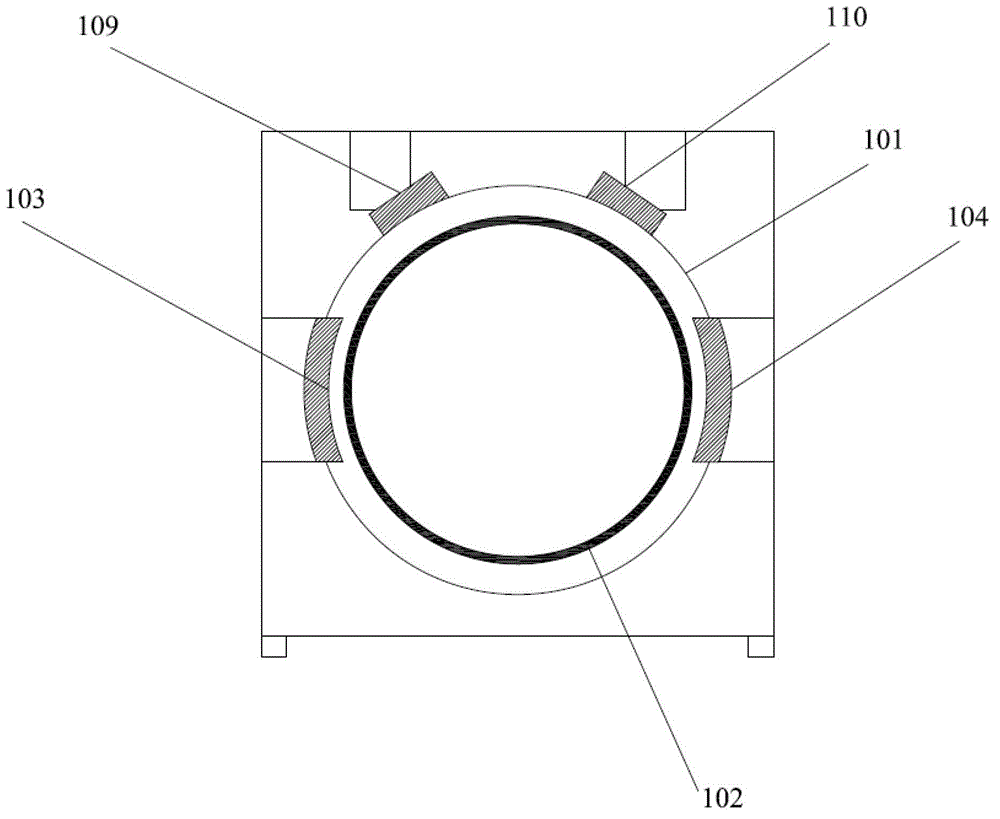

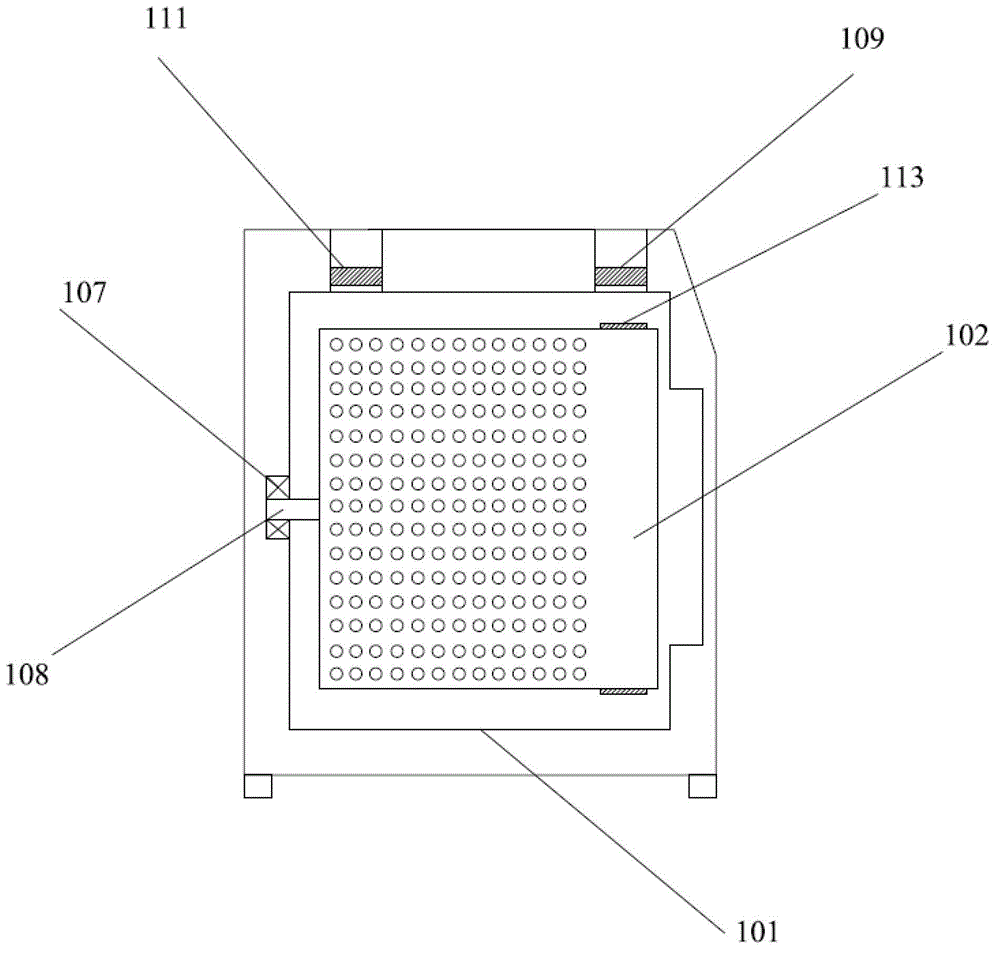

[0015] Such as figure 2 As shown, the washing machine provided in this embodiment includes:

[0016] The inner cylinder 102 and the outer cylinder 101 are provided with a primary coil along the circumference of the outer cylinder 101, and the inner cylinder 102 is correspondingly provided with a secondary induction part, and the primary coil generates magnetic force with the secondary induction part to drive th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com