Synchronizers for transmissions

A technology for synchronizers and transmissions, applied to clutches, mechanically driven clutches, mechanical equipment, etc., to achieve the effects of saving weight, increasing durability, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

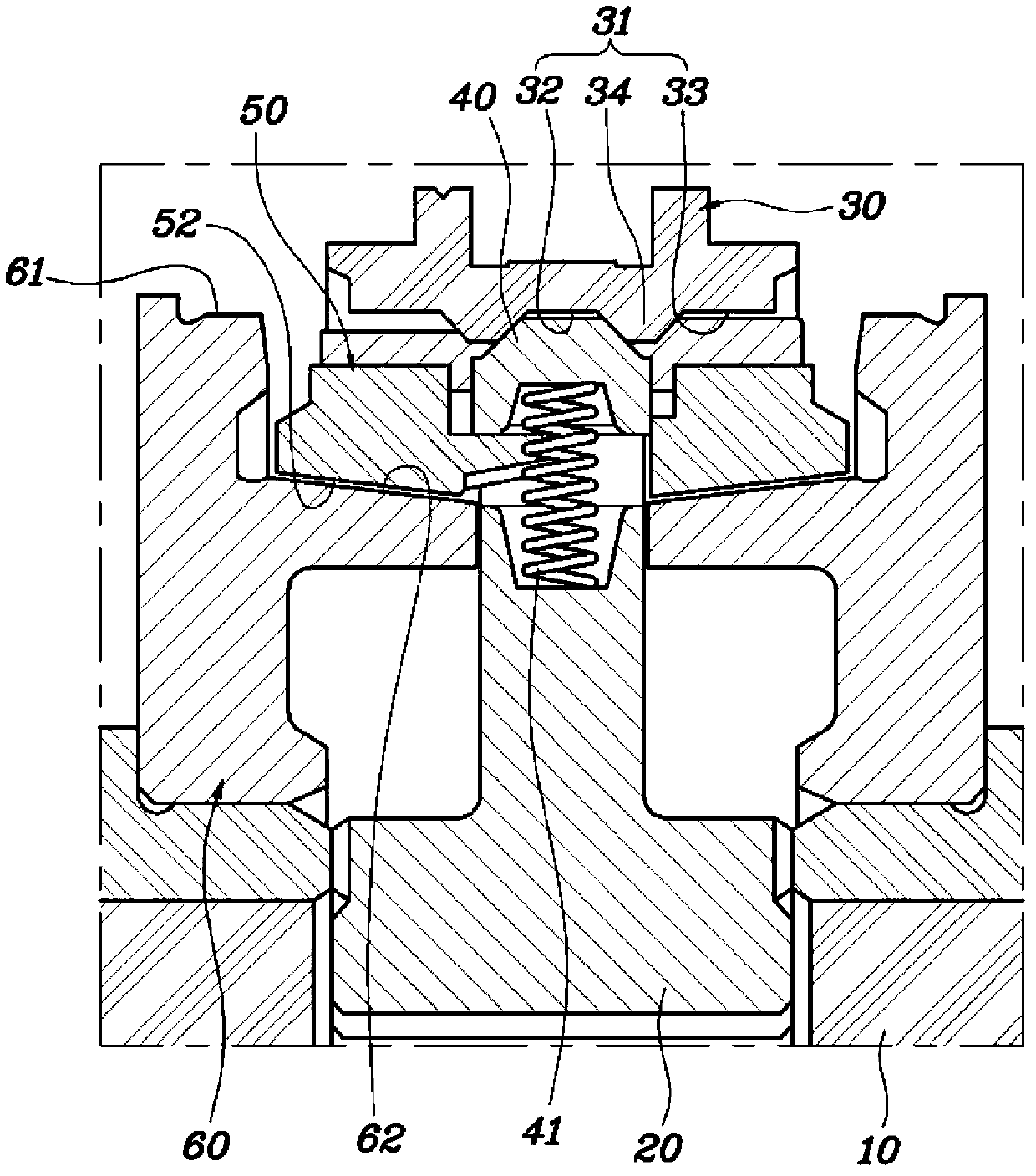

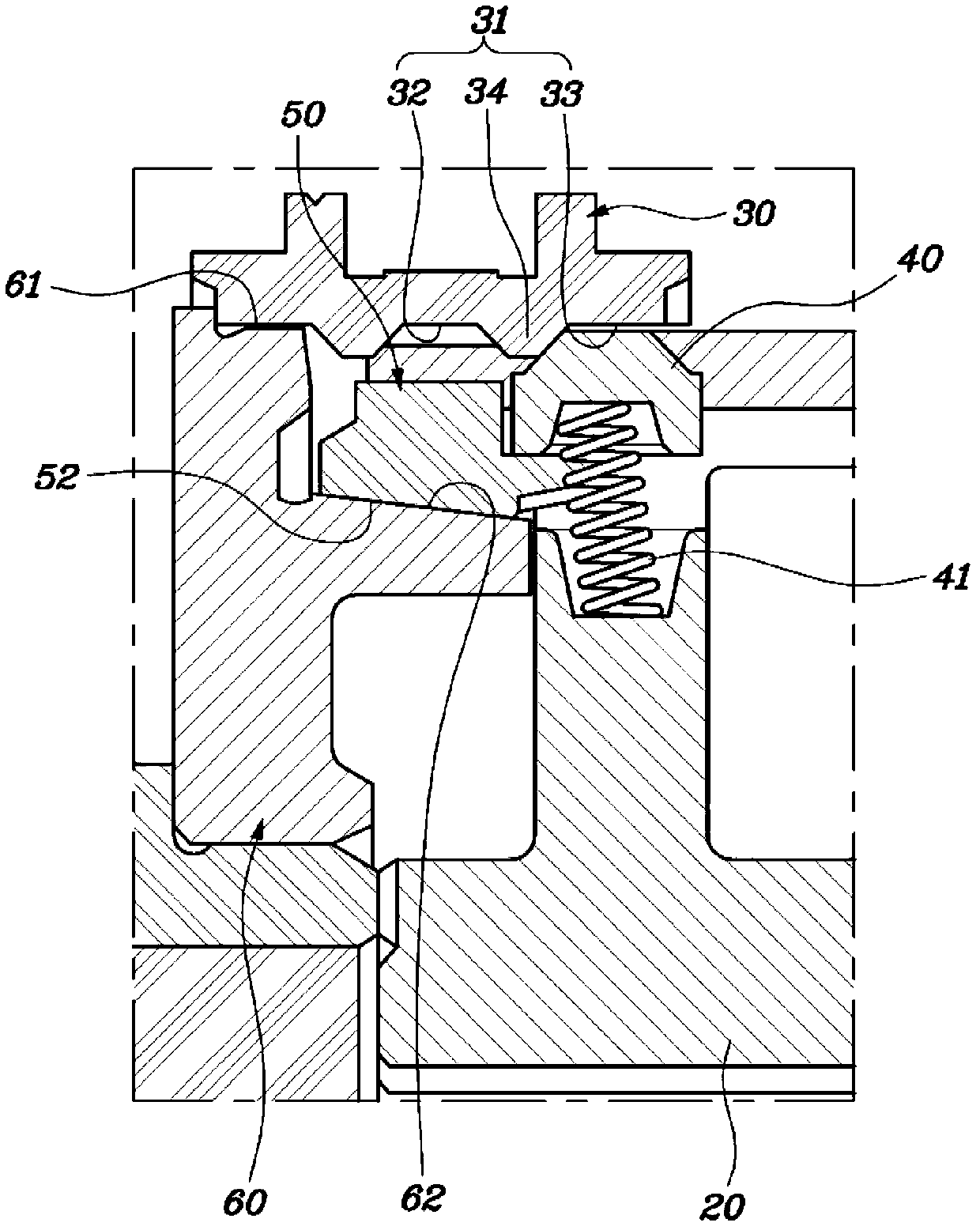

[0030] Reference will now be made in more detail to preferred embodiments of the invention, an example of which is shown in the accompanying drawing. Wherever possible, the same reference numbers will be used throughout the drawings and the specification to refer to the same or like parts.

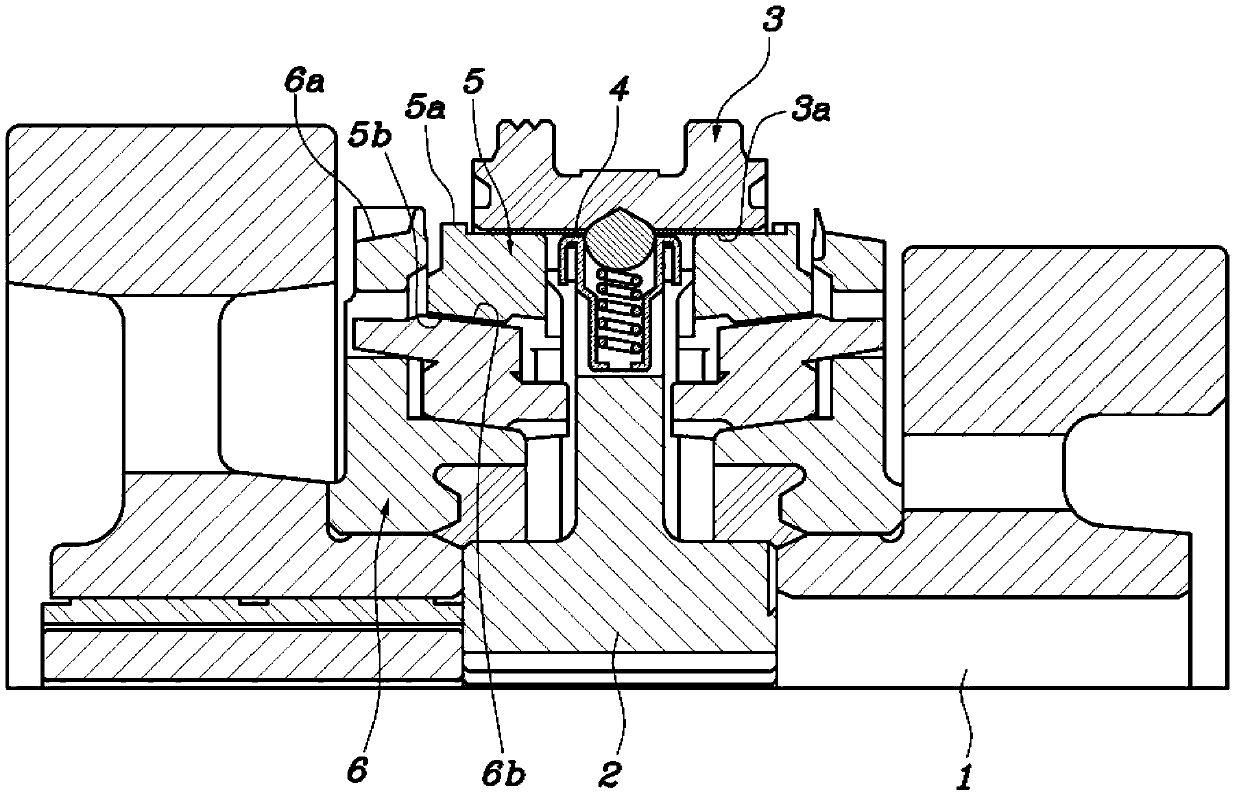

[0031] figure 2 A view showing the structure of a synchronizer for a transmission according to the present invention in a state before its synchromesh; image 3 is a view showing the structure of a synchronizer for a transmission according to the present invention in a state after its synchronous engagement; and Figure 4 is a view of the shape of the shift gear 31 formed on the inner circumference of the sleeve 30 in the synchronizer, wherein the teeth of the shift gear have different thicknesses;

[0032] refer to Figures 2 to 4 A synchronizer for a transmission according to the present invention generally includes a sleeve 30 , a synchronization key 40 , a synchronizer lock ring 50...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap