LED (light emitting diode) luminous subassembly and lamp thereof

A technology of LED lamps and light-emitting components, applied in the field of lamps and lanterns, can solve the problems of limited area, scrapped light-emitting components, lack of insulation and withstand voltage, etc., and achieve the effect of ensuring the insulation and withstand voltage, increasing the welding layer area, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain and illustrate the technical solution of the present invention, the present invention will be described in detail through specific examples below.

[0036]

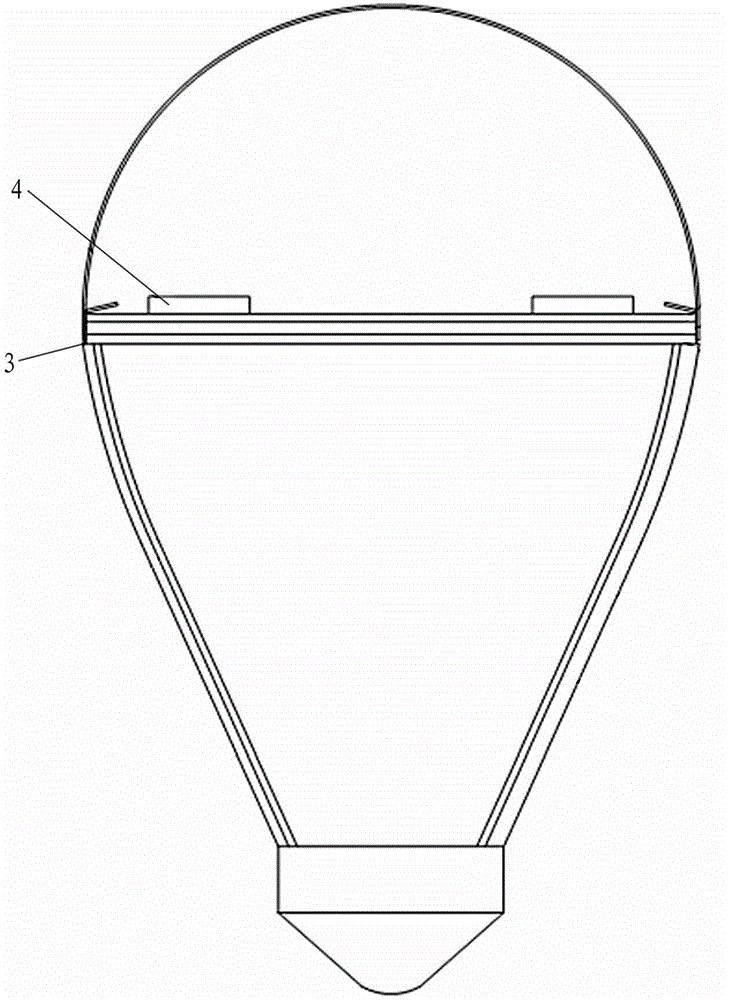

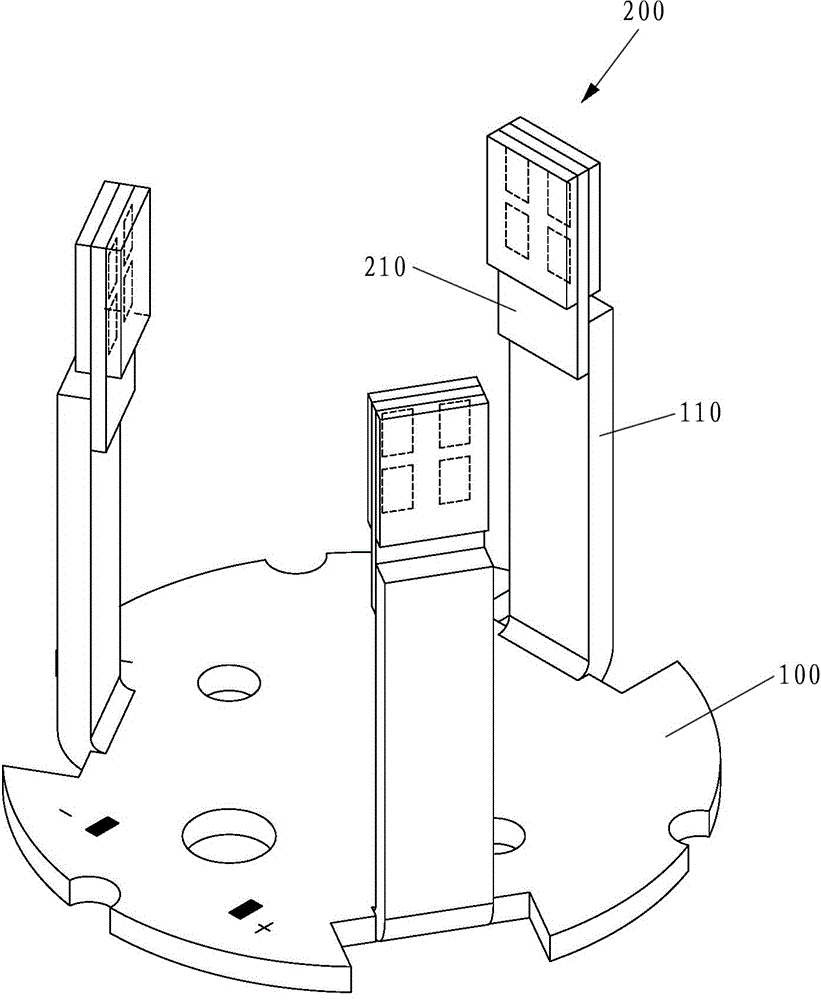

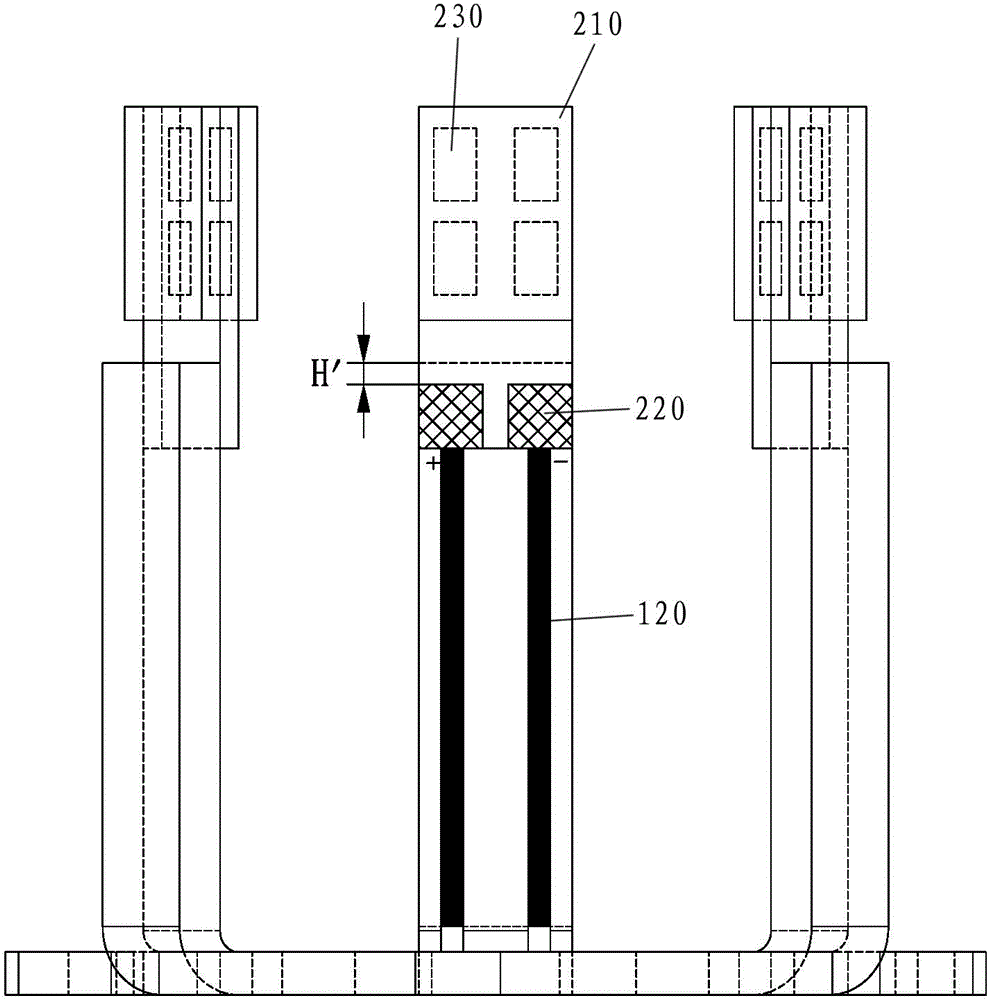

[0037] Such as Figure 3-1 to Figure 3-4 As shown, an LED lighting assembly includes an LED illuminant 1 with bidirectional light emission and an L-shaped bracket 2 for fixing the illuminant.

[0038] The bidirectional LED illuminant 1 includes a transparent substrate 11 , LED light emitting chips 12 and a wavelength conversion layer 13 . The transparent substrate 11 is made of transparent alumina or aluminum nitride ceramics. The material itself has certain thermal conductivity but no electrical conductivity. Its front and back surfaces are respectively the first main surface 111 and the second main surface 112. A first conductive circuit 113 for supplying power to the LED light-emitting chip 12 is arranged on one main surface. The two main surfaces 112 are transmitted, so the light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com