Optical imaging system

An optical imaging system and optical technology, applied in optics, instruments, photography, etc., can solve the problems of inability to brighten the outer surface of semiconductor chips, shadows in images, etc., to avoid blind spots or uneven brightness, and improve imaging quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

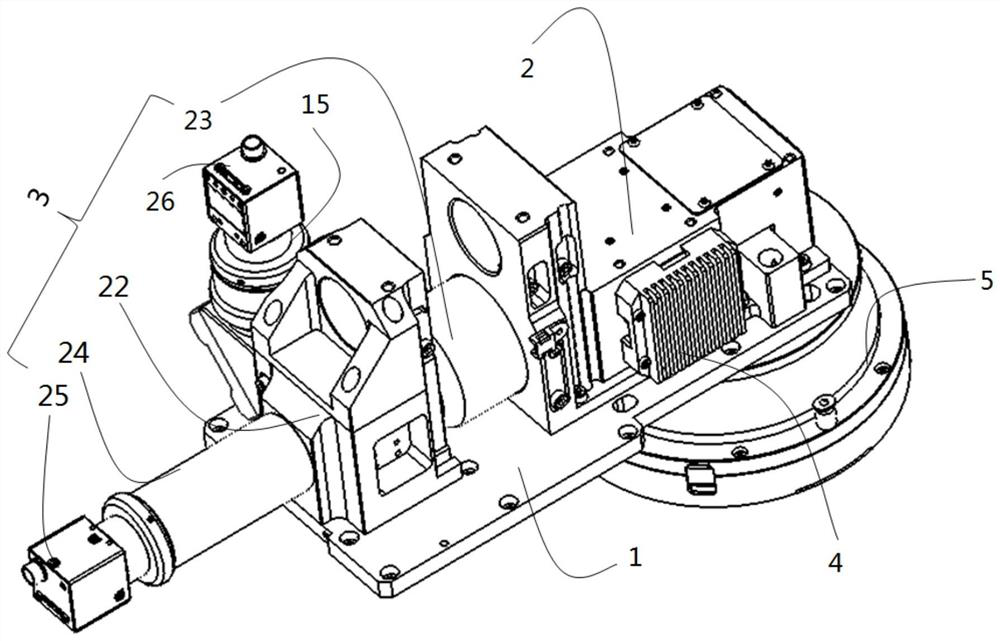

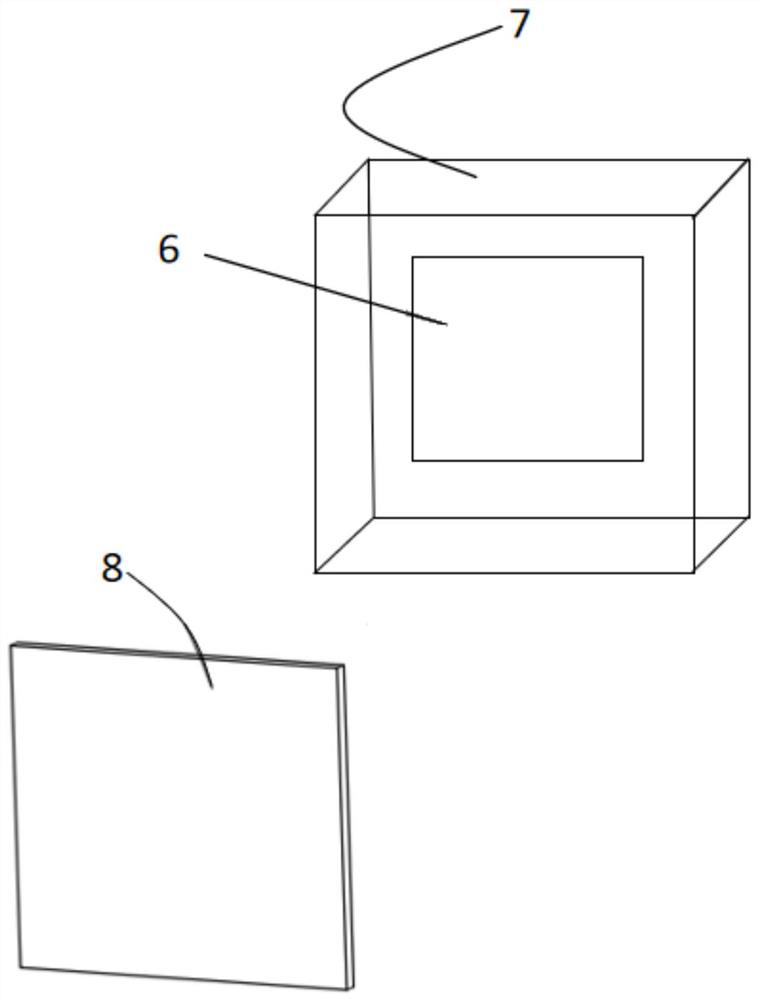

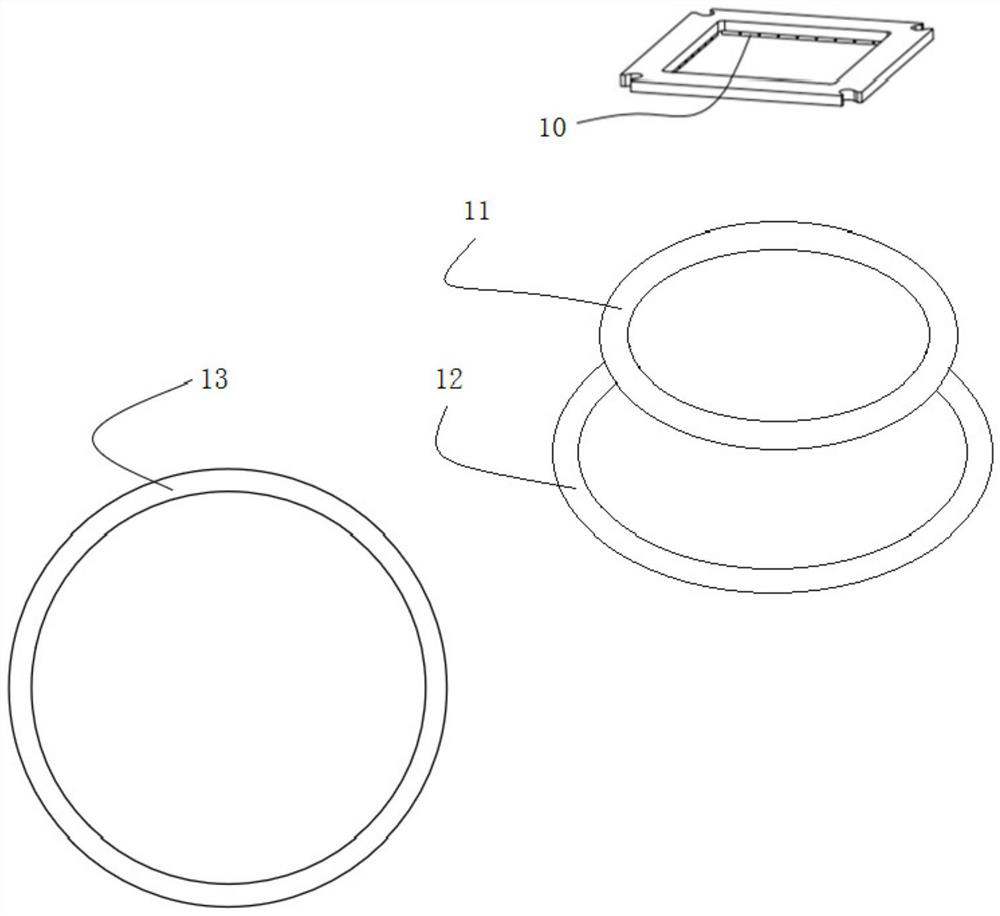

[0056] The invention discloses an optical imaging system, please refer to figure 1 , figure 1 It is a schematic diagram of the first structure of an optical imaging system provided by the present invention. The embodiment of the present invention includes an optical main panel 1, an optical module 2, a camera module 3, a side coaxial light source module 4 and a multi-angle light source module 5; wherein, the optical main panel 1 is a common plate-shaped structure, on which Several connecting holes are provided for connecting with each module to support each module. The optical module 2 and the camera module 3 are both arranged on the surface of the optical main plate 1, and the camera module 3 is set towards the refracted light direction of the optical module 2, the optical module 2 is used to transmit the reflected light of the measured object to the camera module 3, and the camera module 3 is set on the optical path of the characteristic imaging light of the measured object...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com