Portable tensioning/twisting composite material mechanical property testing machine

A composite material and portable technology, applied in the field of machinery, can solve the problems of knowledge connection, the difficulty of combining students' theoretical knowledge, the specificity of transmission methods, and the difficulty of students' abstraction in visual imagination, so as to achieve exquisite appearance and small overall size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

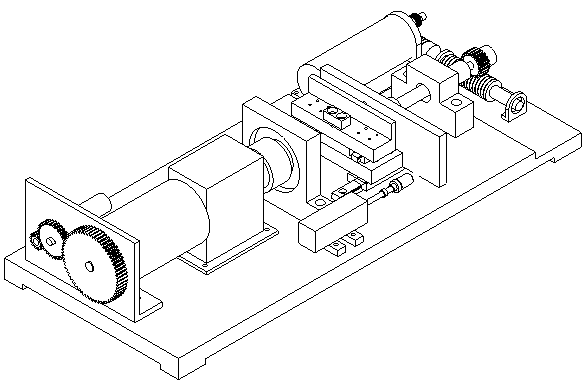

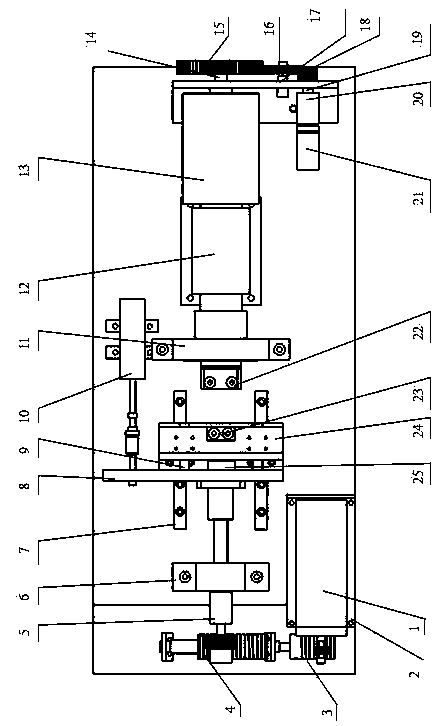

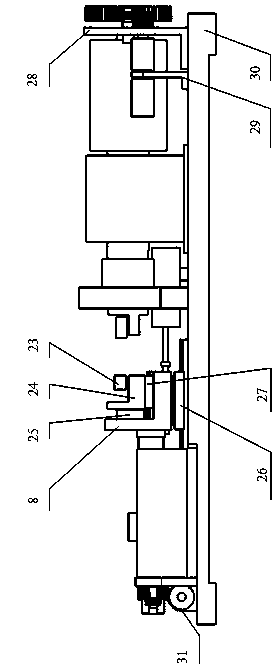

[0022] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0023] see Figure 1 to Figure 3 As shown, the portable tensile and torsion composite mechanical performance testing machine of the present invention includes a stretching unit and a twisting unit, and the stretching unit and the twisting unit are respectively fixed on the base 30; the stretching unit is: motor base a2 The motor a1 is fixed on the top, and the motor seat a2 is fixedly connected with the bottom plate 30; in order to output and achieve the effect of transmission and reversing tension, the motor a1 is connected with the worm gear a, b3, 4, screw nut 5 and the tension seat group in sequence; , Worm gear a, b3, 4 are all fixed by worm gear seat group 31, leading screw nut 5 is fixed by bearing and leading screw nut seat 6, and worm gear seat group 31 and leading screw nut seat 6 are all fixed on the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com