Method and device for detecting lithium battery power

A technology of power detection and lithium battery, which is applied in measuring devices, secondary batteries, measuring electrical variables, etc., and can solve the problem of high cost of special chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

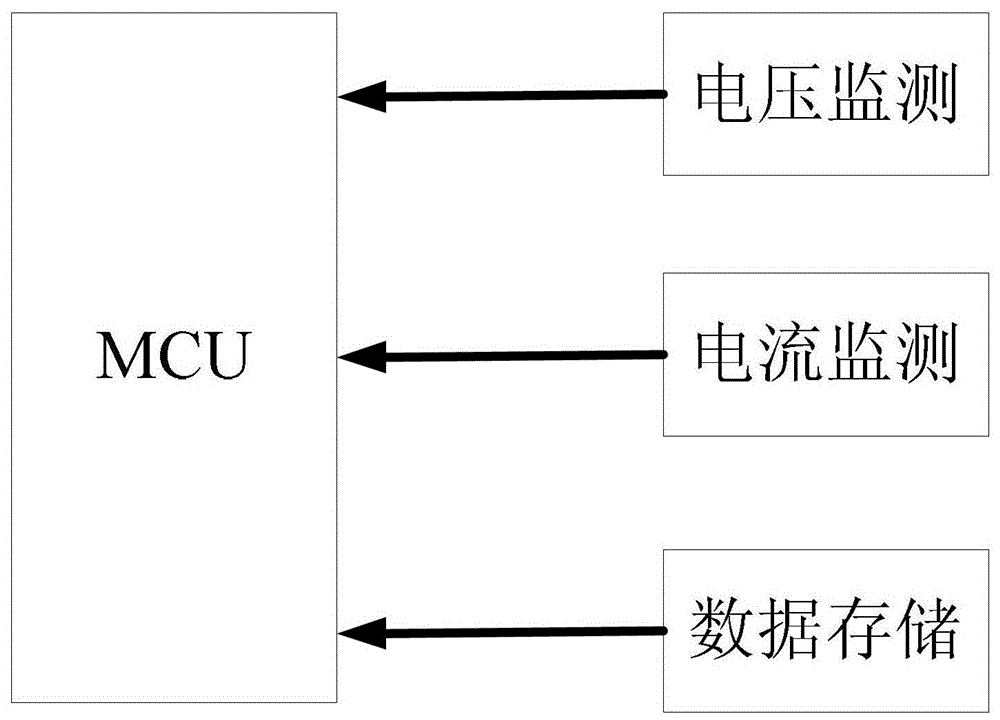

[0018] In the first embodiment, the following method is used to detect the electric quantity of the lithium battery:

[0019] The first step is to calibrate the battery, and the total power Q of the battery is calculated by the data acquisition and processing module S And the value of the calibration parameter of each sampling point obtained through sampling is stored in the data storage unit;

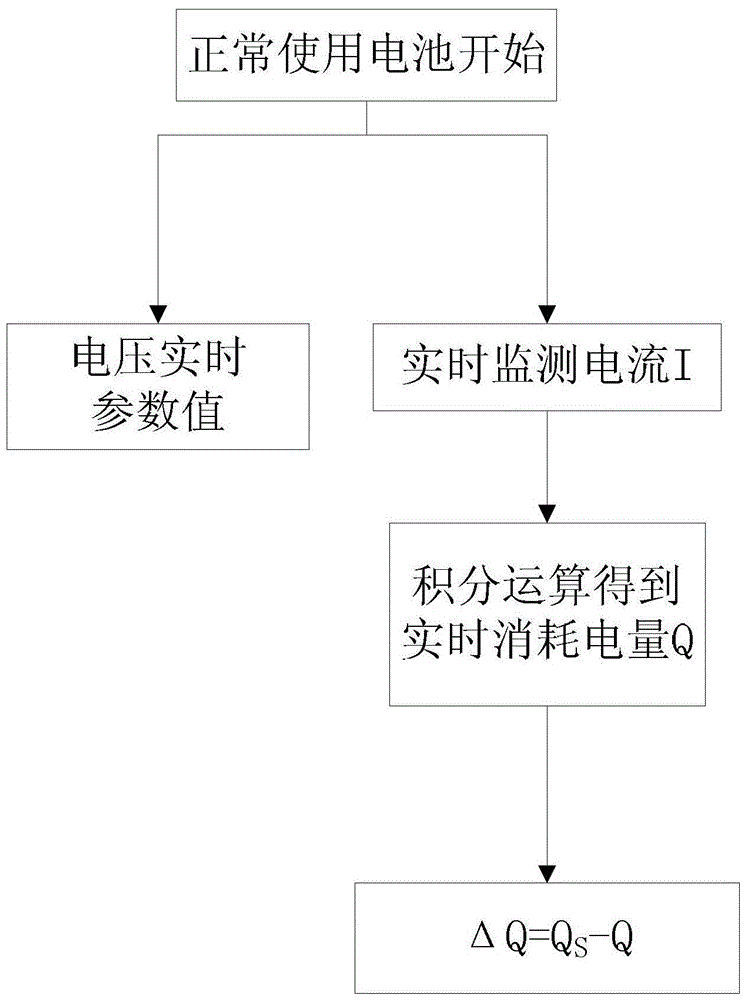

[0020] The second step is to use the calibrated battery normally, and collect the battery current I and the real-time parameter value of the calibration parameter in real time through the data acquisition and processing module, and use the integral calculation of the current I and time to obtain the real-time consumed power Q;

[0021] The third step is to compare the real-time parameter value with the corresponding calibration parameter value. If the difference between the real-time parameter value and the corresponding calibration parameter value is less than the preset value, the t...

no. 2 example

[0028] In the second embodiment, the following method is used to detect the electric quantity of the lithium battery:

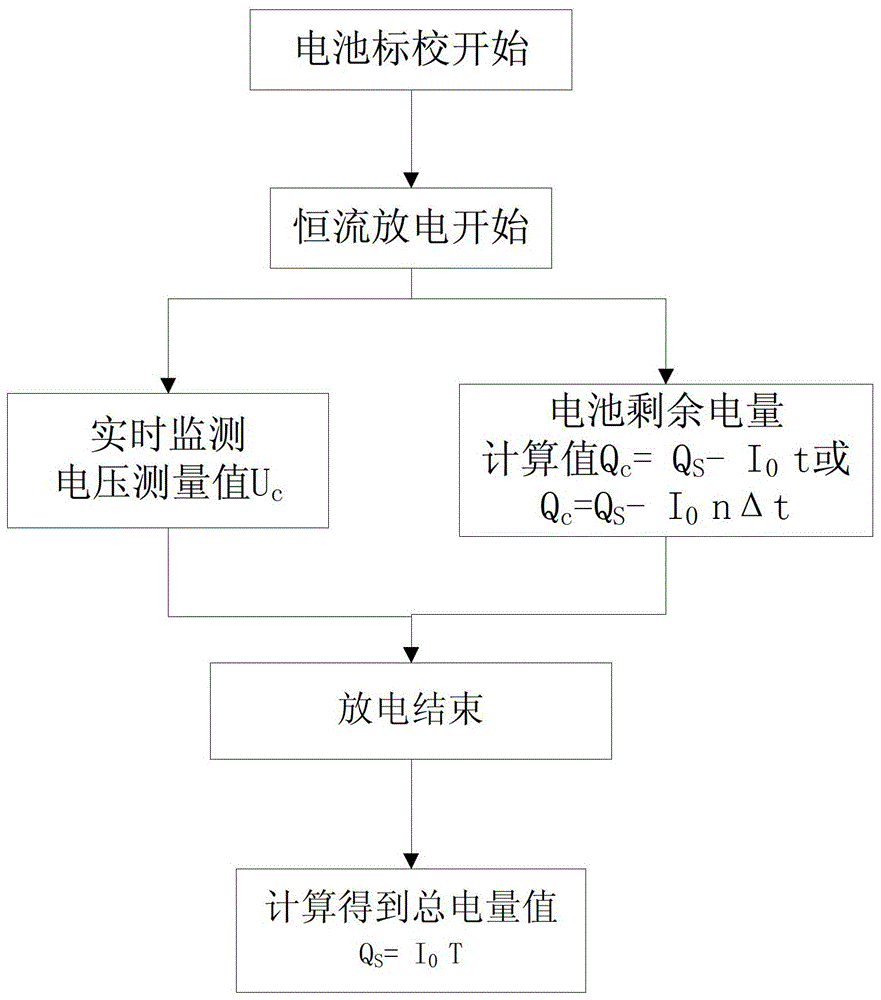

[0029] The first step is to calibrate the battery, using a constant current I 0 The method of discharging the battery is carried out, as attached figure 2 As shown, until the end of discharge, the total battery power value Q is obtained S , Q S = I 0 T, where T is the time spent until the end of discharge. The discharge time is segmented, and a sampling point is selected for each stage. The total power Q of the battery is calculated by the data acquisition and processing module S And the value of the calibration parameter of each sampling point obtained through sampling is stored in the data storage unit, and the calibration parameter value includes the measured value of the battery voltage, and its measured value is marked as U during the calibration process. c ; and the calculated value of the remaining battery power, which is recorded as Q in the ca...

no. 3 example

[0039] In the third embodiment, the following method is used to detect the electric quantity of the lithium battery:

[0040] The first step is to calibrate the battery, as attached figure 2 shown, using a constant current I 0 The method of discharging the battery is carried out until the end of the discharge to obtain the total battery power value Q S , Q S =I 0 T, where T is the time spent until the end of discharge. The discharge time is segmented, and a sampling point is selected for each stage. The total power Q of the battery is calculated by the data acquisition and processing module S And the value of the calibration parameter of each sampling point obtained through sampling is stored in the data storage unit, and the calibration parameter value includes the measured value of the battery voltage, and its measured value is marked as U during the calibration process. c ; and the calculated value of the remaining battery power, which is recorded as Q in the calibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com