Simulation testing method for mixed coarse aggregate compactness

A simulation test, coarse aggregate technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of difficult to monitor the mesoscopic structural characteristics of mixed coarse aggregate, lack of mixed coarse aggregate, coarse aggregate grade Problems such as long configuration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

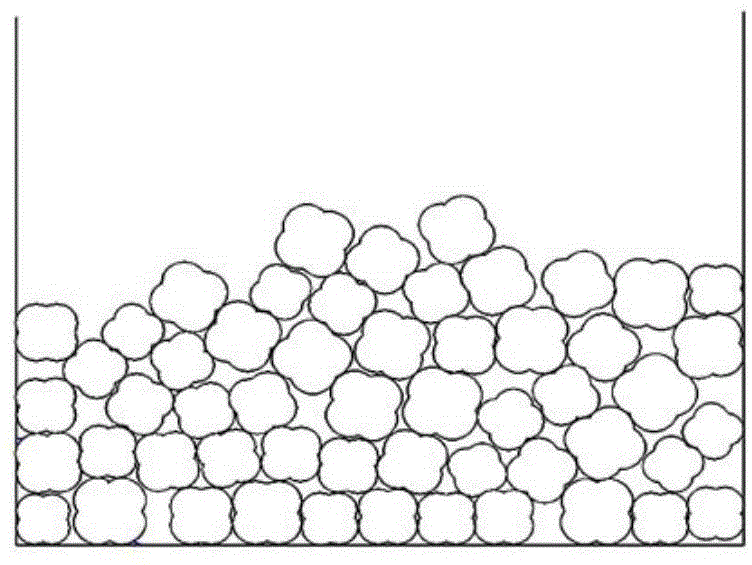

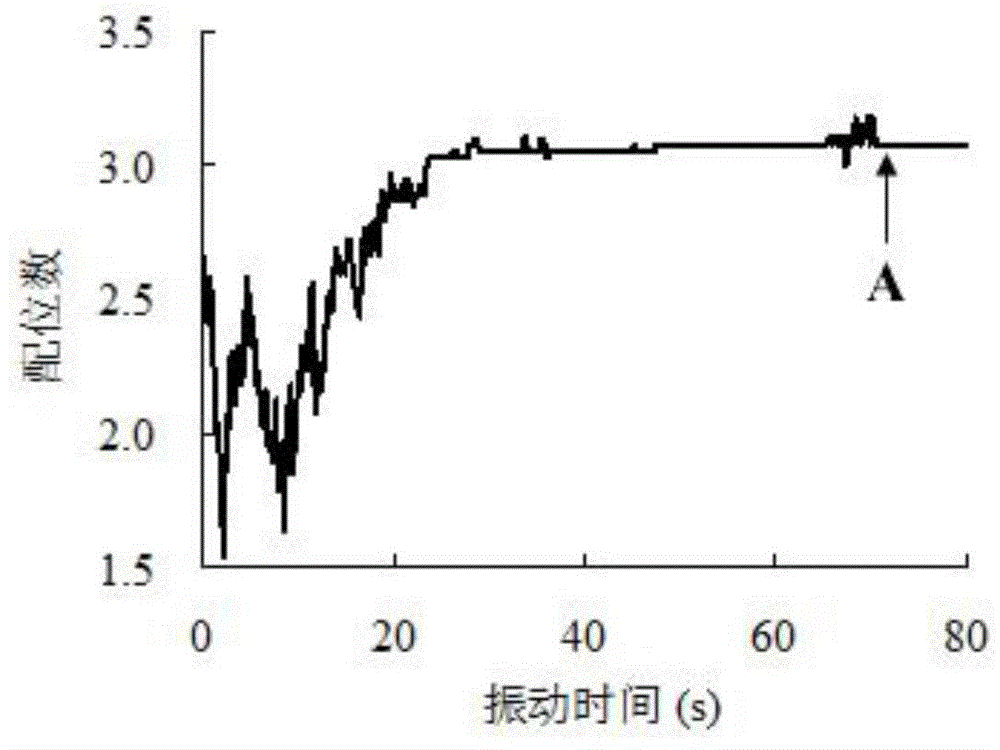

[0071] According to the technical scheme of the present invention, this embodiment provides a simulation test method for the compactness of mixed coarse aggregates, using 19-31.5mm coarse aggregates and 9.5-19mm coarse aggregates with a total mass of 6kg produced in Yinghu, Ankang. The composition of mixed coarse aggregate (mass ratio of 19-31.5mm coarse aggregate to 9.5-19mm coarse aggregate is 100:50) is taken as an example to illustrate the implementation steps of the simulation test method for the density of mixed coarse aggregate:

[0072] (1) Construction of physical model of mixed coarse aggregate

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com