Detecting sensor adjusting device and method and substrate detecting device

A technology for detection sensors and adjustment devices, which is applied to instruments, static indicators, etc., can solve the problems of human resources consumption, high labor costs, and inaccurate adjustments, and achieve the effects of improving detection quality, saving labor costs, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

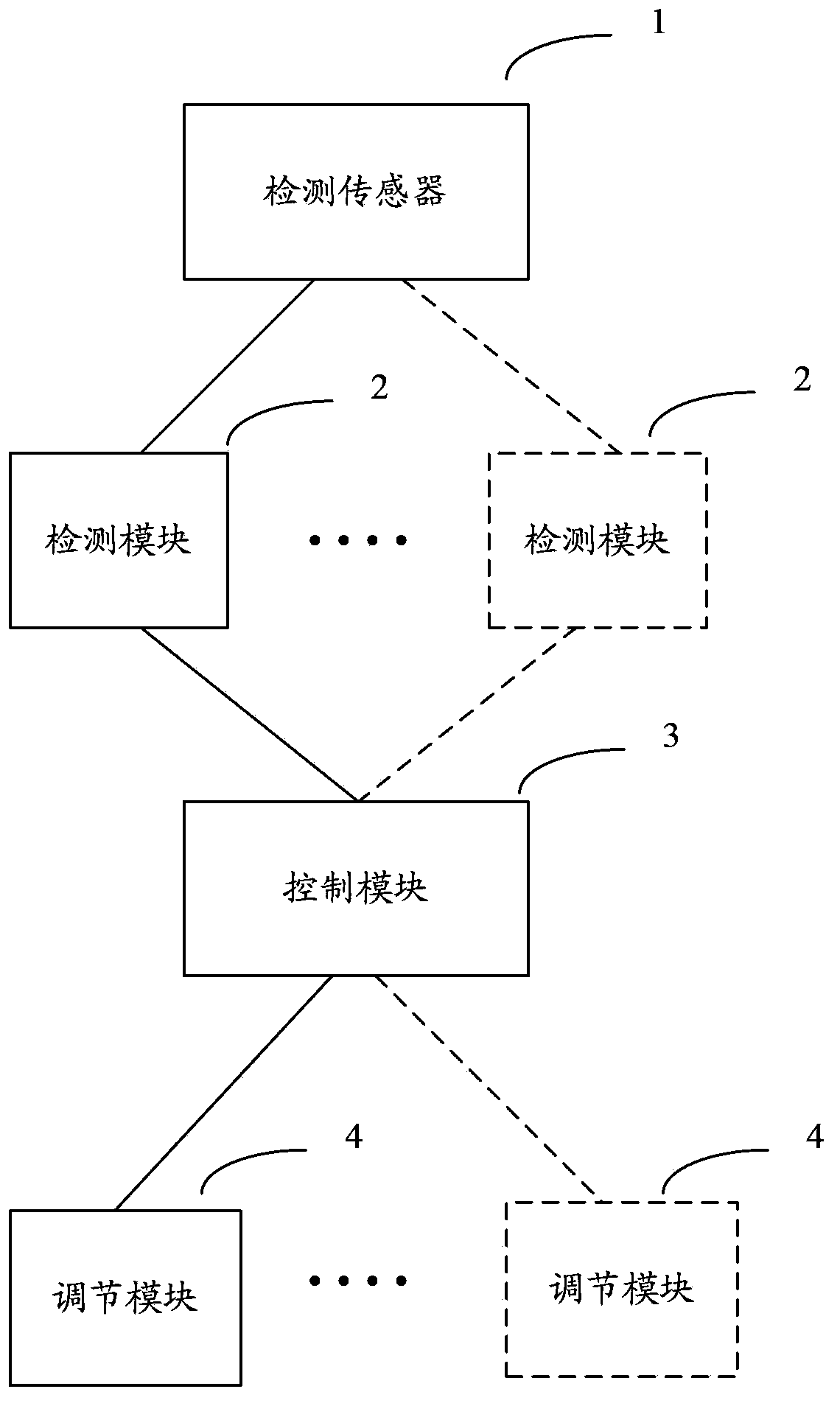

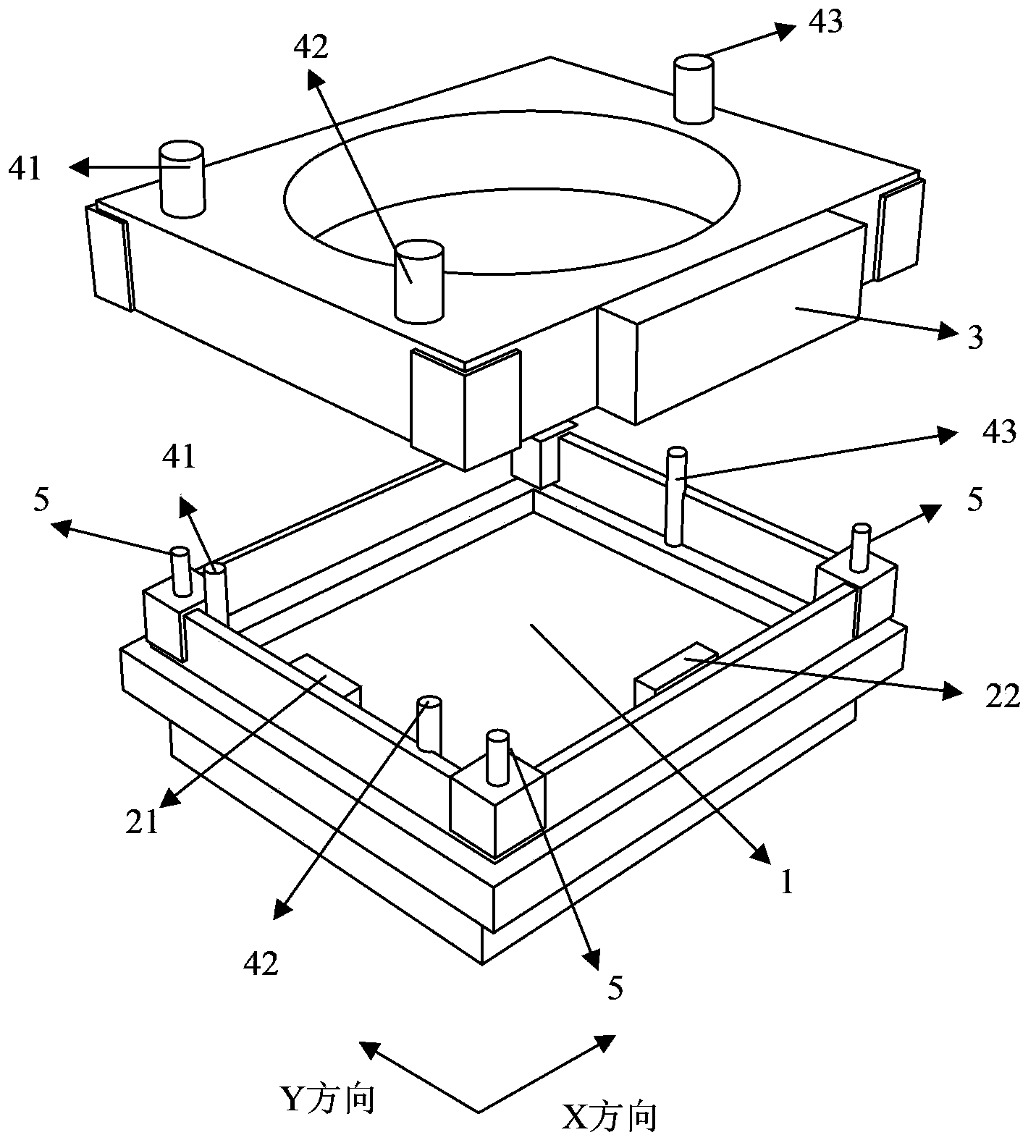

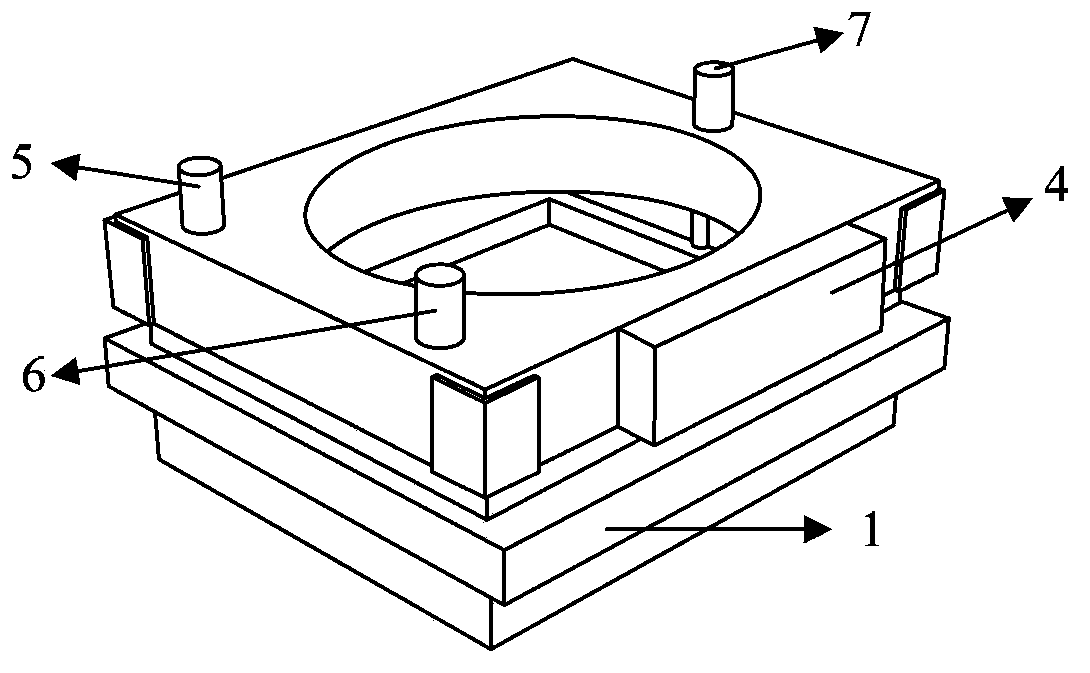

[0047] The basic idea of the present invention is that the substrate detection device includes: a detection sensor, at least one detection module, a control module and at least one adjustment module; wherein, the detection sensor is used to detect the substrate; the detection module is used to detect The levelness of the detection sensor; the control module is used to control the adjustment module to adjust the levelness according to the detection result of the detection module.

[0048] An embodiment of the present invention proposes a detection sensor adjustment device, including: at least one detection module, a control module and at least one adjustment module; wherein,

[0049] The detection module is used to detect the levelness of the detection sensor;

[0050] The control module is configured to control the adjustment module to adjust the level of the detection sensor according to the detection result of the detection module.

[0051] Optionally, the device specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com