IGBT-module installation method

A technology of installation method and installation location, which is applied in the manufacture of electrical components, electric solid devices, semiconductor/solid devices, etc., can solve problems such as module insulation failure, damage to IGBT module subunits in the installation method, module damage, etc., to achieve the goal of solving damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Experience has shown that the early failure of power semiconductor modules is mainly related to incorrect installation, and incorrect installation will lead to unnecessary high junction temperature, which will greatly reduce the working life of the module. So the correct installation of the module is very important.

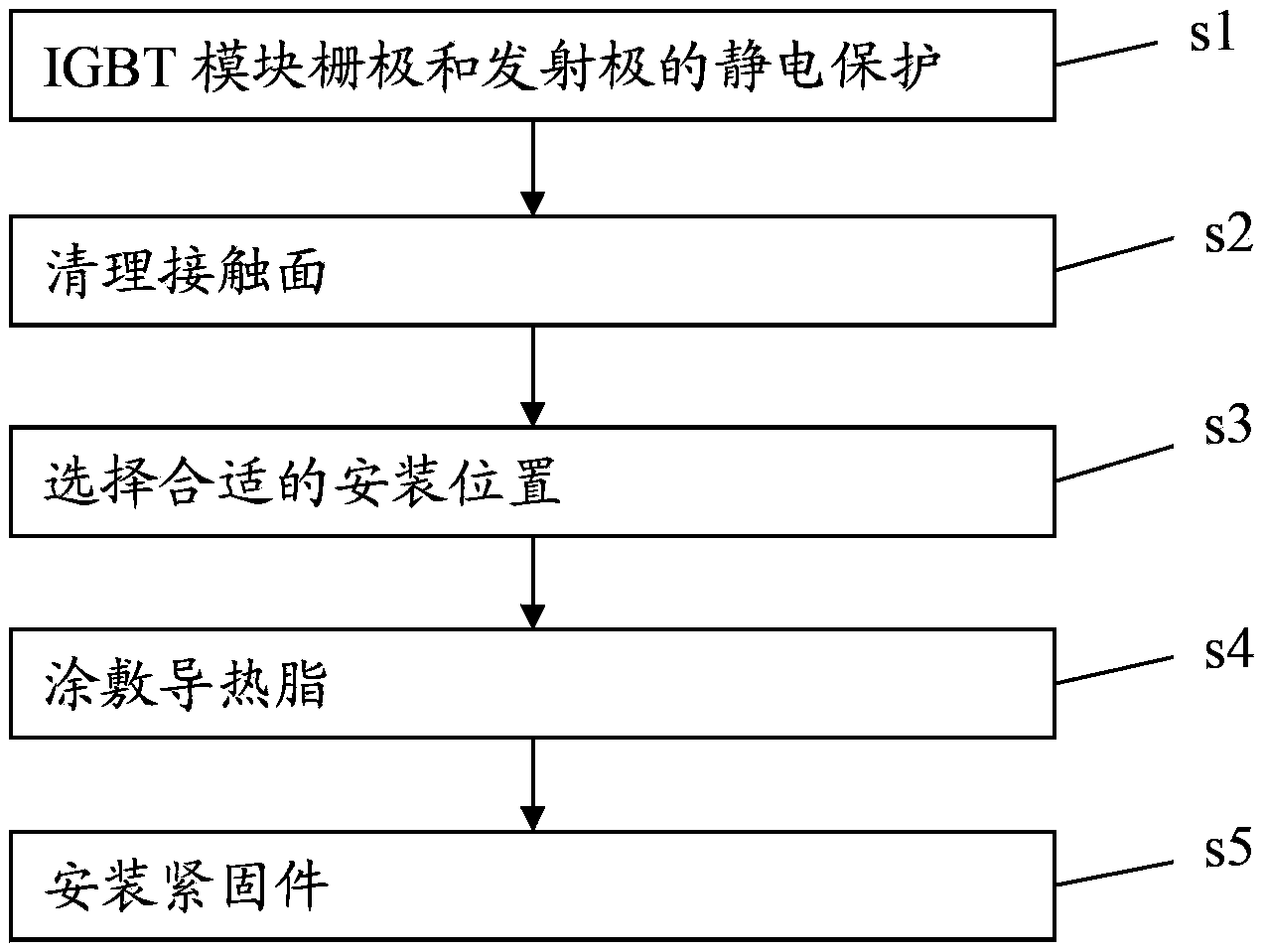

[0027] In view of this, the embodiment of the present invention discloses a method for installing an IGBT module, including:

[0028] s1. Clean the contact surface between the IGBT module and the heat sink;

[0029] s2. Select a predetermined installation location;

[0030] s3, coating thermal grease between the IGBT module and the heat sink;

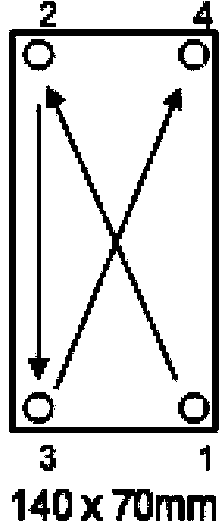

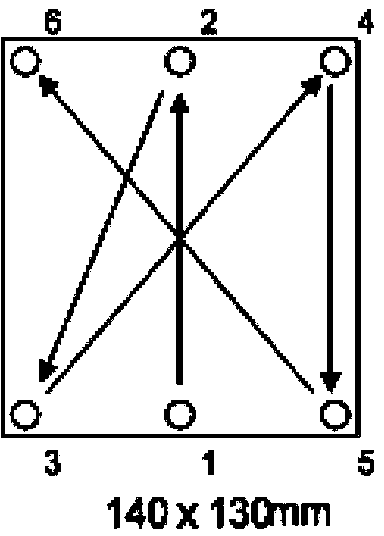

[0031] s4. Install fasteners. All fasteners used to fix the IGBT module must be tightened with a consistent torque, and the fasteners should be tightened in diagonal order.

[0032] The above solves the damage caused by the installation process of the high-power IGBT module, and can better improve the reliability...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com